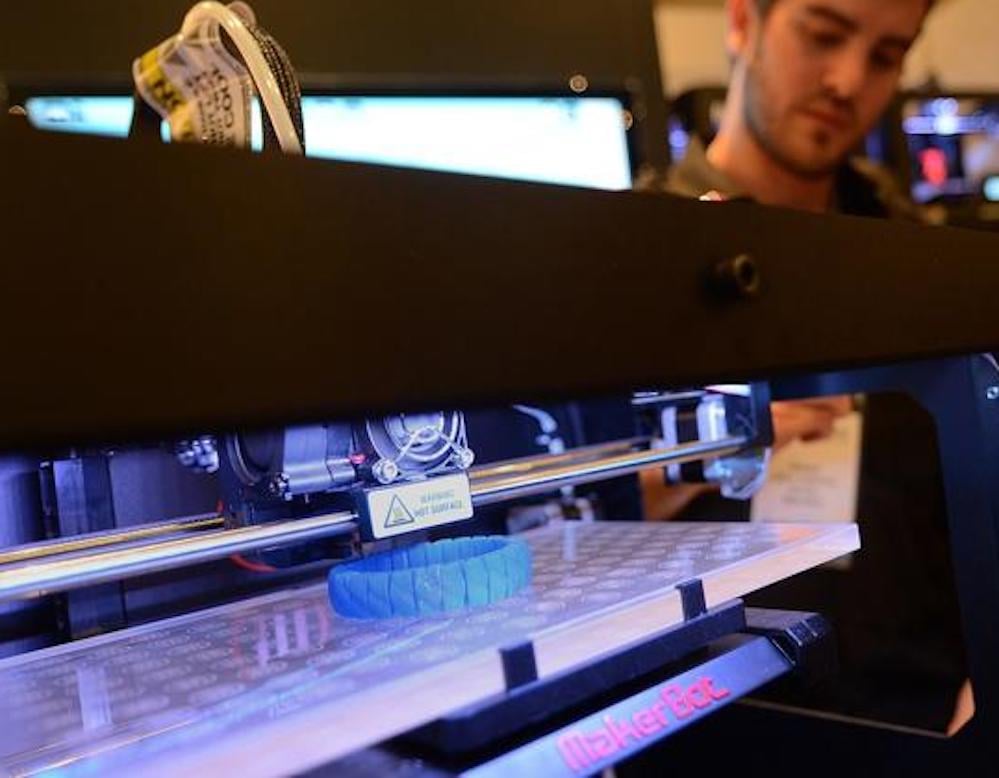

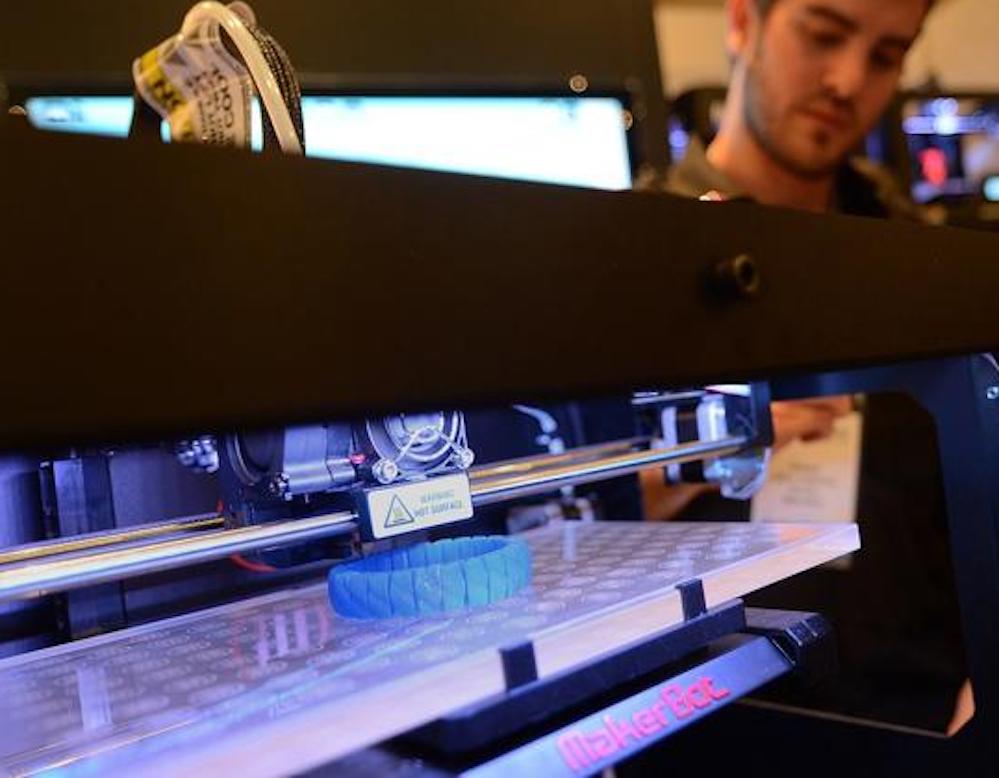

Last week we wrote on the invisible problem of nanoparticles not being caught by typical HEPA filters. One company may offer a solution.

Poland-based 3DKreator’s CEO, Emmanuel Perrin contacted us regarding their filtration solution, which as far as I can tell, is entirely unique in 3D printing.

But first a quick refresher on the problem from our previous story: As typical desktop 3D printers heat up thermoplastic, the material emits tiny nanoparticles of sizes ranging from 0.012 – 0.116 microns. Meanwhile, the typically standard HEPA filters used in some equipment to capture them tap our at 0.300 microns, meaning the majority of the nanoparticles escape filtration and end up in your workplace.

We recommended using external filtration as the solution, but Perrin has another view:

I agree fully with this article. I would only challenge the solution : agree that it is better to have an external ventilation/exhaust system to protect the users ….but are we sure this is great for the environment ???

That is true, although the nanoparticles will eventually hit the ground by weather effects and not remain in the air, where they might in a closed workshop with recirculating air systems. Nevertheless, an accumulation of such particles on land is also probably not the best idea.

Perrin’s company, 3DKreator, seems to have developed a much more effective filter. He explains:

We have developed a filter which combine HEPA filtration (to filter the “big” particles) with Photocatalyse filtration (to destroy the organic chemistry like Styrene). The results is that we get rid of 84% of the organic chemistry while HEPA get rid of the big particles. All our machines are enclosed and equipped with our SYNE filtration to limit as much as possible the effect of the 3D printing emission and we are developing a stand alone version that could be fitted everywhere.

This hybrid approach appears to be much more effective.

3DKreator’s Co-Founder, Przemek Kazanowski, explains further:

It’s called SYNE – air filtration system for 3D printers. Basically speaking all hazardous fumes and toxics coming out from 3D printing processes SYNE innovation changes into CO2. This solution is a must if you would like to have a healthy 3D printing in your office or in school.

I am still disappointed that the industry has not yet picked up on the safety considerations of the equipment they have been building. There are still far too many machines that have no recognition that this may be a problem.

Over the past several years, we have seen many formerly “advanced” features creep into the market and become defacto standards that are expected to be on any reasonable 3D printer. They include: automated calibration, self-adhering print surface, LCD control panel, WiFi, and filament break detection.

One of these days proper filtration will also make that list, but it is not today.

Via 3DKreator