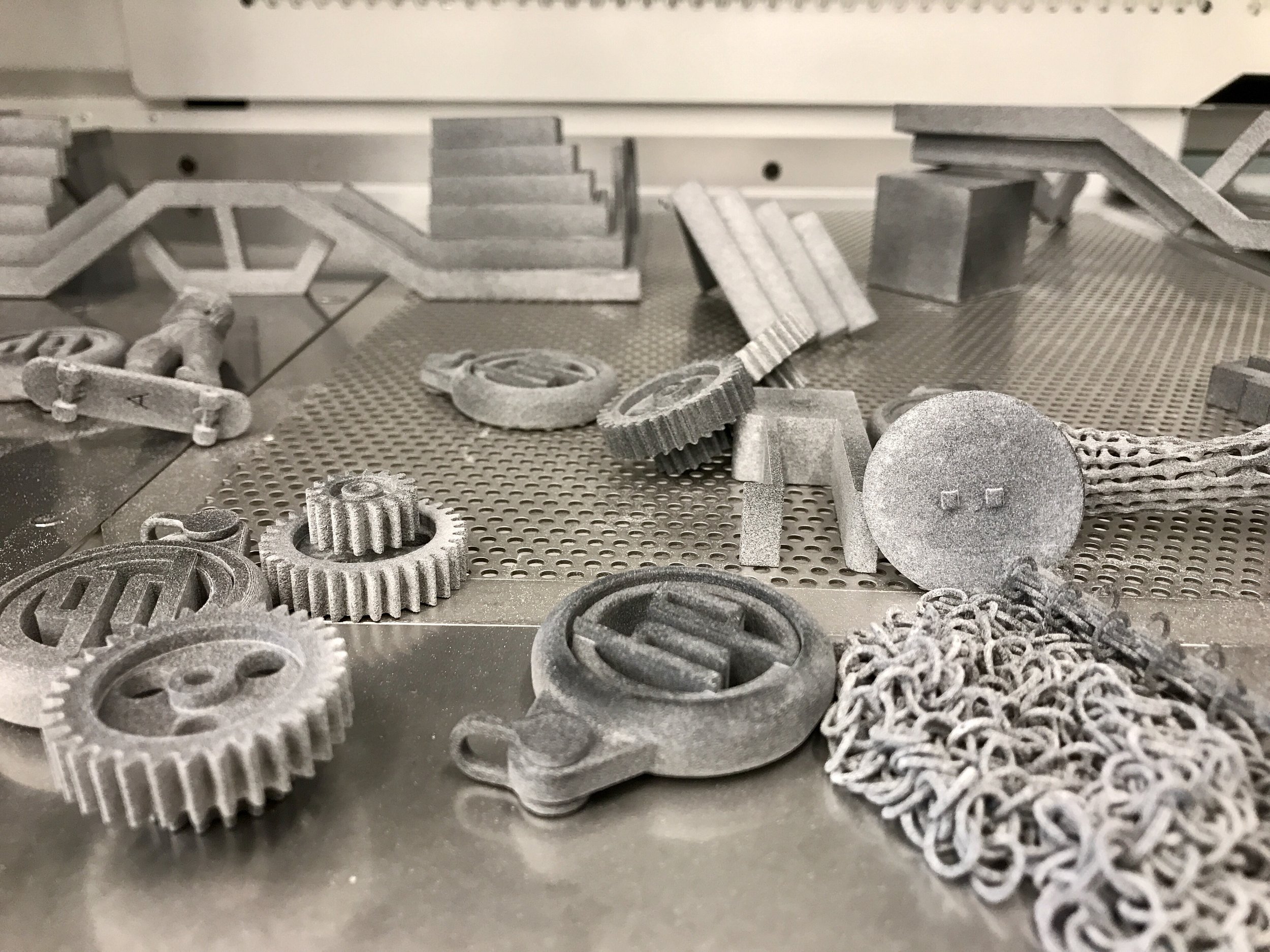

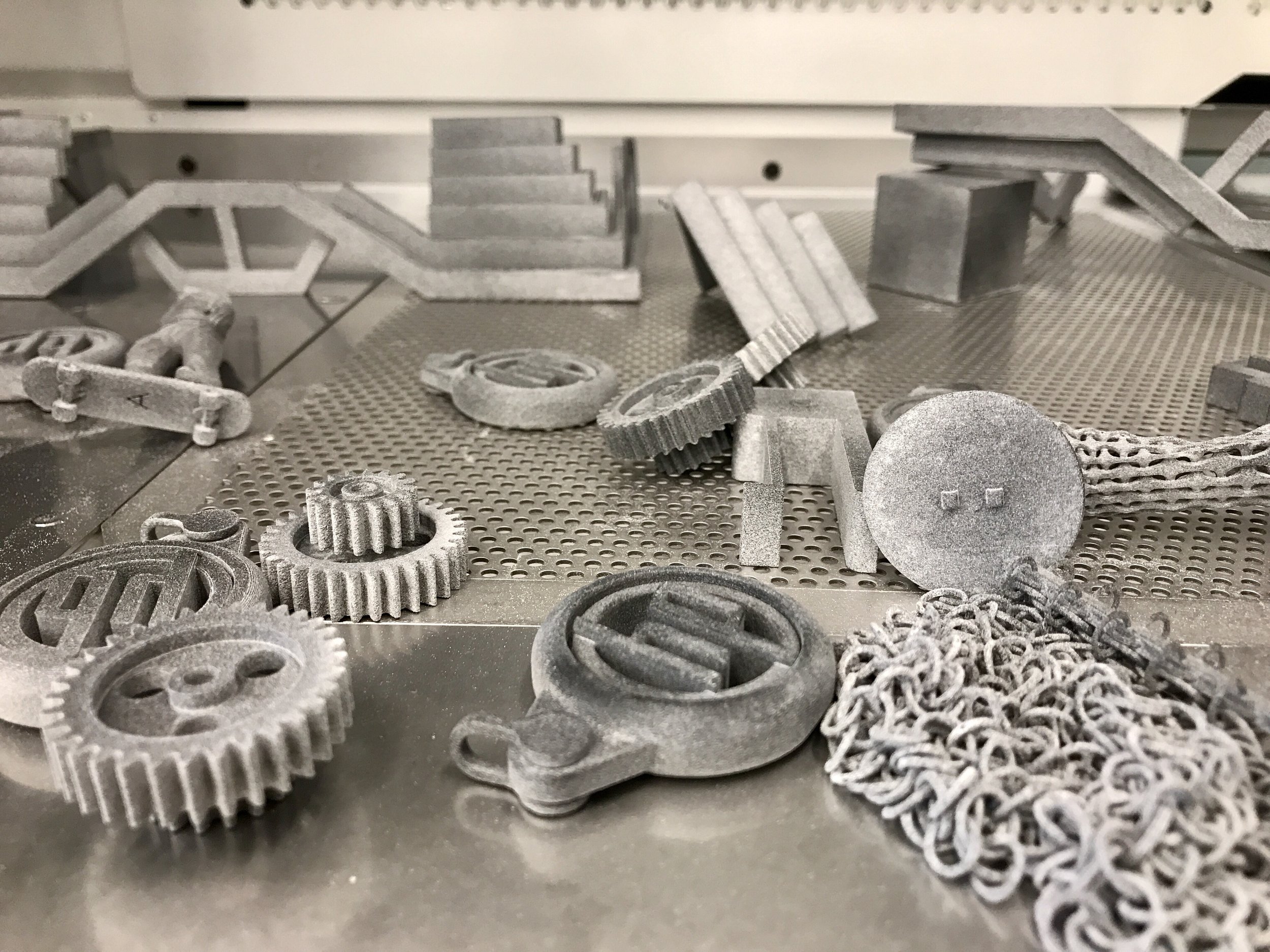

HP’s 3D Open Materials and Applications Lab, is a 3,500 square-foot space where 3D materials partners can jumpstart product development, test new materials and get real-time feedback from engineers.

Fabbaloo asked Timothy Weber, Global Head, 3D Materials and Advanced Applications at HP, about the size of their R&D Department. Weber said that the HP R&D department is comprised of approximately 100 employees, all material experts, with many being chemists with PhD’s. There are not very many 3D printer manufacturers that can boast of such materials expertise on hand.

HP’s open materials platform enables 3D print materials for their equipment to address a wider range of manufacturing needs and applications. While HP launched their equipment with a relatively small set of materials, they have big ideas for the future, and apparently the means to produce them.

HP are adding colour and changing material properties (softer in places for unique production ready parts), and some materials even have sensors built in enabling new IoT applications. HP has employed this technology already with an example of a medical device 3D printed in plastic and then coated with additional materials with sensors to provide doctors with real time data on how the device (or new knee) is performing in a human body.

HP does this with voxel by voxel layers and can change the attributes of each and every voxel’s rigidity, colour, electrical properties. A complex base product can be 3D printed using this capabilty, but that’s not the end of it: coating the print with other materials opens up many other possibilities.

This capability is one strong advantage for HP in the 3D printer market: the ability to vary the properties of the material at a voxel level is extremely powerful and quite unique. Most other 3D printing processes involve but a single material at a time, or maybe a few more. HP’s approach could enable direct 3D printing of far more complex objects, and possibly even functioning electronics eventually.

But for now, HP is still the newcomer on the 3D printing block and has yet to widely adopted by industry. It’s their job to connect with manufacturers and explain how this process works and how it might be profitably used for specific business ventures.

That will be quite a challenge, as voxel-level materials control is so far away from most manufaturing operations that most designers would not yet know how to most effectively levereage it in new product concepts.

But that will come in time.