Prusa Research took an expected, but nevertheless interesting step forward this month by announcing a feature usually found on professional machines.

Prusa Research is well known for producing the ridiculously popular Original Prusa i3 MK2S desktop 3D printer, which many have been drawn towards due to its high reliability, ease of use, excellent quality prints and, of course, its rock bottom price.

We’re told the company is selling multiple thousands of units per month and recently expanded their production facilities in Czechia to accommodate the demand.

But it is a hobby machine, is it not?

Maybe not as much as you think, after their announcement that their new release of slicing software, Slic3r Prusa Edition version 1.36.2, includes the ability to use water soluble support material.

Certainly this is only physically possible on their multi-extruder machine, the Original Prusa i3 MK2 MultiMaterial, a machine that can handle up to four different filaments simultaneously. You could print in up to four different colors, for example.

But multi-extruder machines at the professional level are increasingly being used not for color, which is less important when producing a functional part. Instead, the extra material being most frequently used is water-soluble support material.

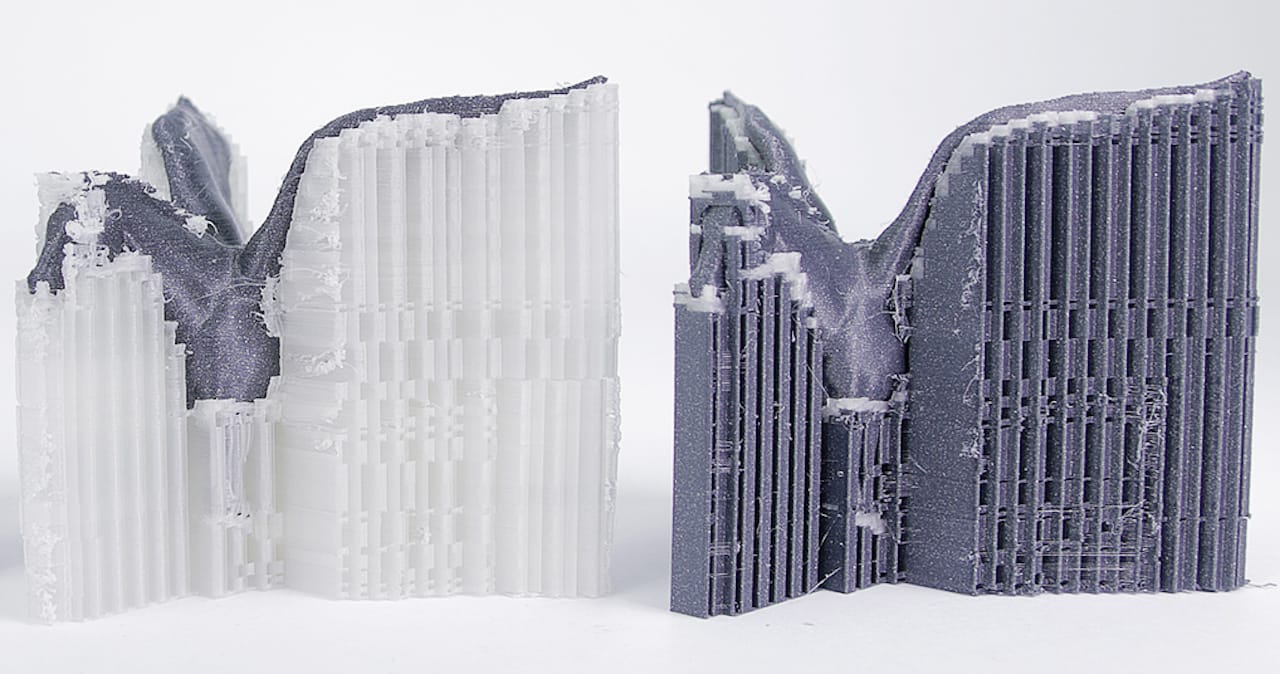

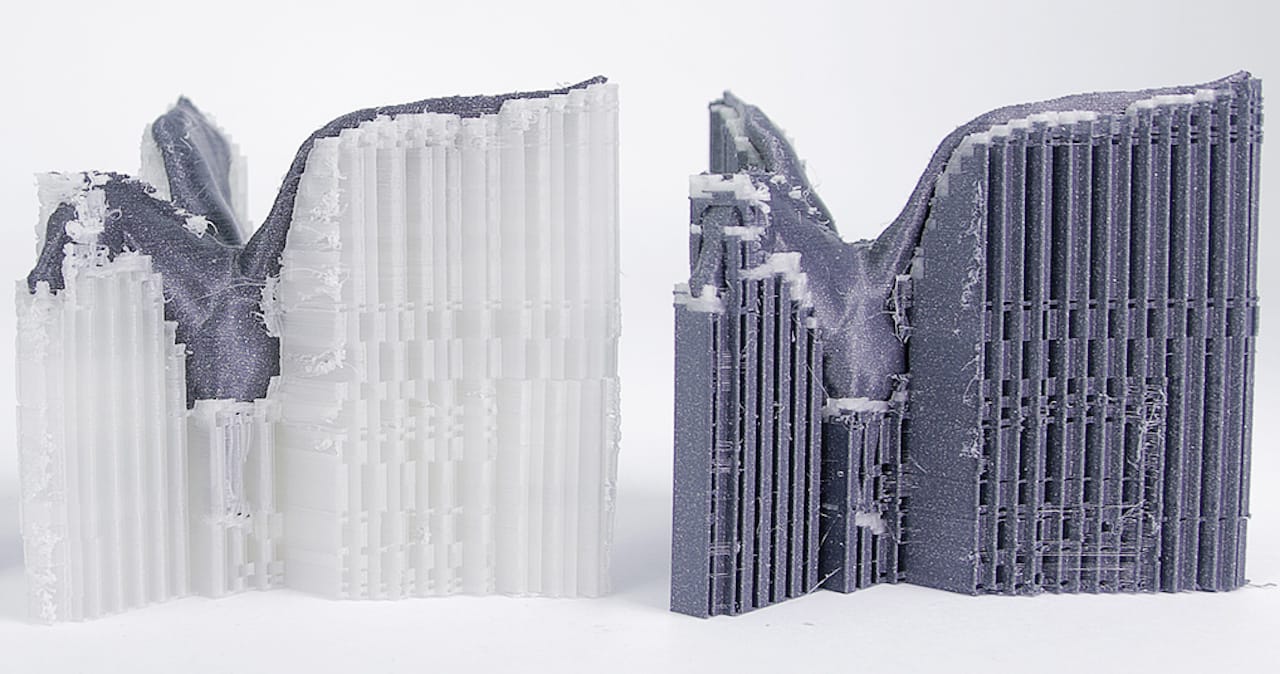

The importance of this capability cannot be understated. With it, 3D print operator is much more reliably able to 3D print objects with arbitrarily complex – and delicate – geometries. Without support you are at the mercy of gravity and thermal effects. Essentially you simply stop worrying about the shape of the object and just print it because you know it will almost certainly succeed.

But now the latest version of Prusa’s slicing software also supports soluble support. This means that you can access a key feature of professional desktop 3D printers at a cost far lower than buying one, if you were to use Prusa’s configuration.

Of course, another feature of professional desktop 3D printers these days is the ability to 3D print high temperature materials, and that isn’t on the menu for Prusa, at least not yet. Such a move would likely require the company to add an enclosure to capture heat and upgrade a number of mechanical components to be able to withstand the higher temperatures.

This would probably be a big deal for Prusa, as they currently 3D print much of the parts for their product – in ABS, a material perhaps with a softening temperature too low for use in a high temperature environment. In other words, they’d probably have to rejig their manufacturing process significantly, so I would not expect this to happen anytime soon.

However, the addition of soluble support capability is a big deal for the company and workshops who have been contemplating getting into 3D printing for part prototyping but are reluctant to spend the bigger cash on more expensive equipment.

Via Prusa