Every once in a while there is a rather unusual new application for 3D printing, and this certainly is one.

TechCrunch reports on a kind of “artificial fruit”. But this fruit is definitely not something you’d like to eat anytime soon. No, it’s actually a very peculiar sensor.

The fruit, in this case is an apple. A 3D printed apple replica is produced, and is loaded with an array of sensors. The apple is then tossed into the production sequence for, in this case, apples. The apples (and sensor) travel through the entire lifecycle, including transport, refrigeration, delays, loading and unloading.

The 3D printed apple-sensor can then report on its experience through the process, enabling improvements.

But why not just place a temperature and motion sensor on the trucks? The paper behind the investigation explains:

There is a need for more realistic monitoring of fruit pulp temperature history throughout the cold chain at a higher spatial resolution inside the cargo. Particularly solutions that are easy to install in a commercial setting are required. For this purpose, a novel kind of fruit simulator – an artificial fruit – has been designed, manufactured and tested. Using a biomimetic approach, it was engineered specifically to match the thermal response of real fruit as close as possible.

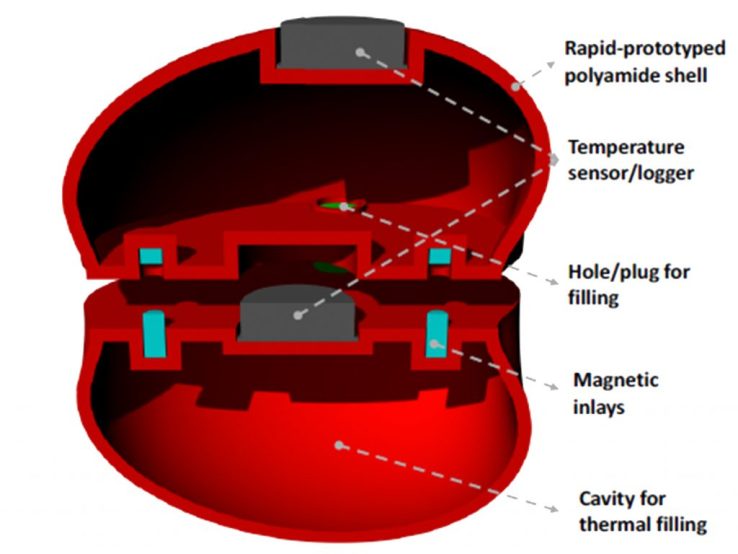

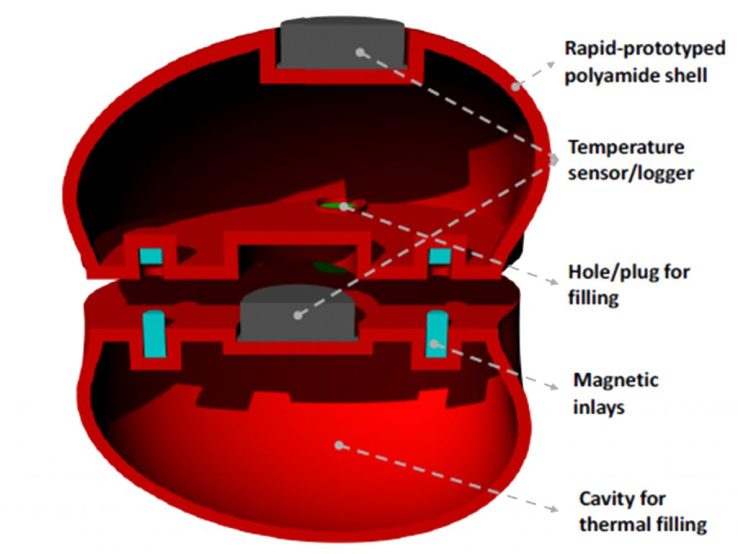

The artificial fruit is composed out of a thin plastic shell, which mimics the exterior size, shape, surface texture and color of the fruit of interest. This shell is filled with a mixture that has similar thermal properties as real fruit as it is basically composed out of the same components. Two self-powered data loggers with a built-in sensor are integrated in the artificial fruit. These different components of the artificial fruit were combined successfully into a manufactured prototype.

Obviously the sensors are removed before the apples reach the customer, although it would certainly be fun to find one in your basket.

The key here is that the apple can be located within different areas of the transport vehicles, collecting data. This can then be used to optimize or even re-develop the transport systems.

It all works because 3D printing technology was able to quickly produce a sensor shape that matched the particular cargo. One can easily imagine this being used for a wide variety of alternative perishable items to provide similar improvements.

Via TechCrunch and Science Direct