With the increase in use of desktop 3D printers in professional offices comes another issue: air quality.

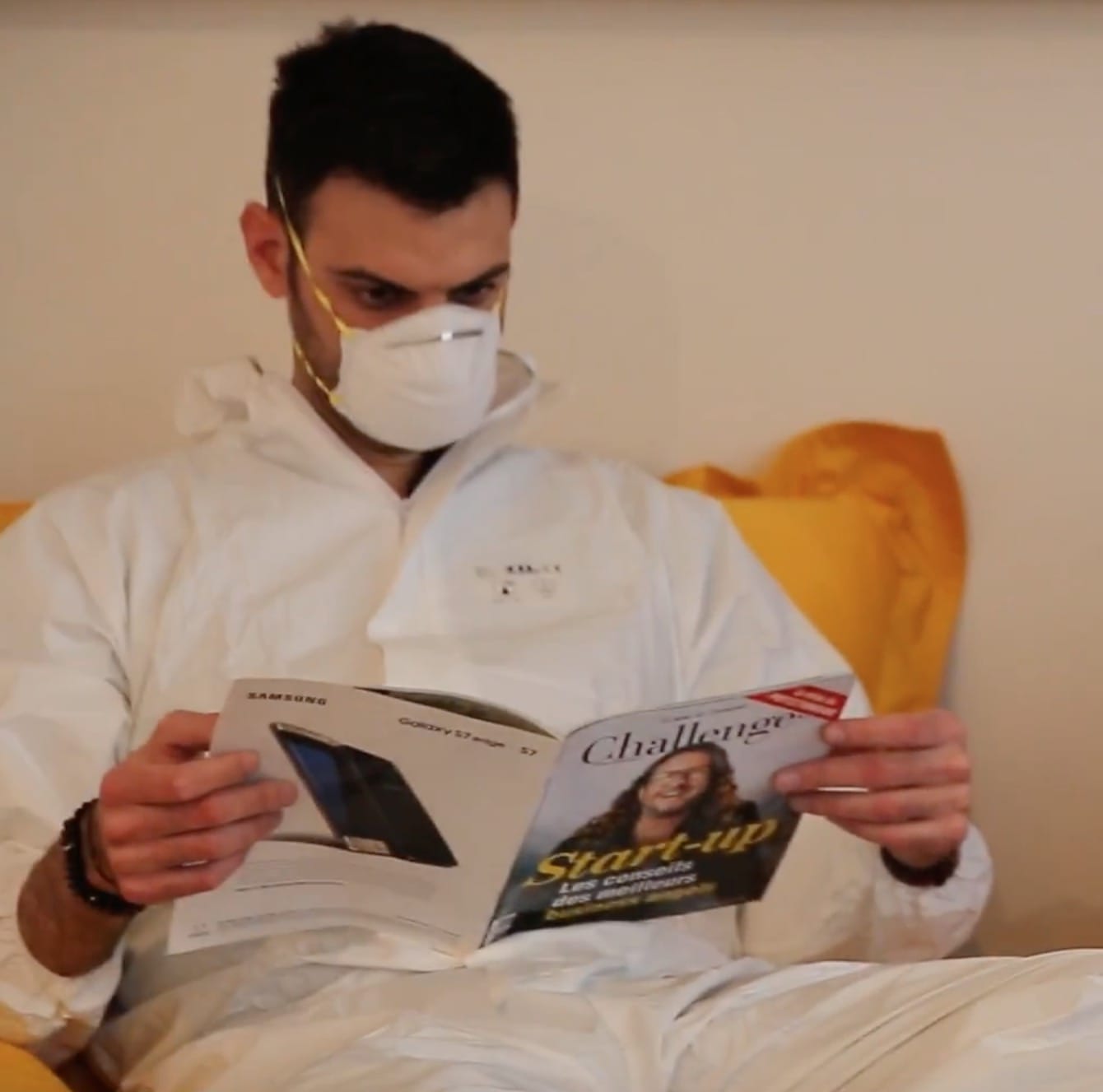

In the consumer craze of desktop 3D printing between 2012-2015, many people were installing equipment in their homes, where they would merrily 3D print all types of material. These machines would most certainly emit nanoparticles and gases into the local atmosphere, sometimes right beside sleeping operators!

One can debate the degree of toxicity generated by desktop 3D printers, but anyone with a cautious attitude would simply avoid or deal with the problem in some way.

But there were few ways to do so. One way was to purchase equipment that included appropriate air filtering technology, so that the local atmosphere would not be polluted. However, few machines today offer such a feature, and in the past it was essentially unheard of.

Another way is to install a blower to take air from your 3D print area and vent it outside. This can work very well, albeit a bit noisy, but it was not a feasible solution in many situations. Consider an internally placed office within a building – where are you venting to? Would your department cough up the cash to put in a very lengthy ducting run to the nearest exterior wall? Not likely.

The final solution for 3D print air quality is to purchase an external air filter that slurps up air from a 3D printer and runs it through several filters. Unfortunately, many of these solutions were for heavy duty industrial use and were prohibitively expensive.

Now there’s a solution that is specifically designed for desktop 3D printers and is actually quite affordable: the Zimpure. They explain the problem:

If we consider that one 3D Printer operates continuously in a well-mixed 45 m3 furnished and conditioned office space (Ventilation rate of 1/hour), we observe an ultrafine particles concentration of 58 000 particles/cm3. It’s more than 11 times higher than what we observe in a typical home, office or school ambient air. Regarding the gases: With this configuration, the predicted styrene concentration is about 150µg/m3, which is 20 times higher than the highest styrene concentration measured in commercial buildings in the U.S. That is not acceptable!

In France, the particles pollution is the 3rd cause of death: more than 48 000 people die every year as a result of particles pollution. We can’t accept even more pollution inside our home!

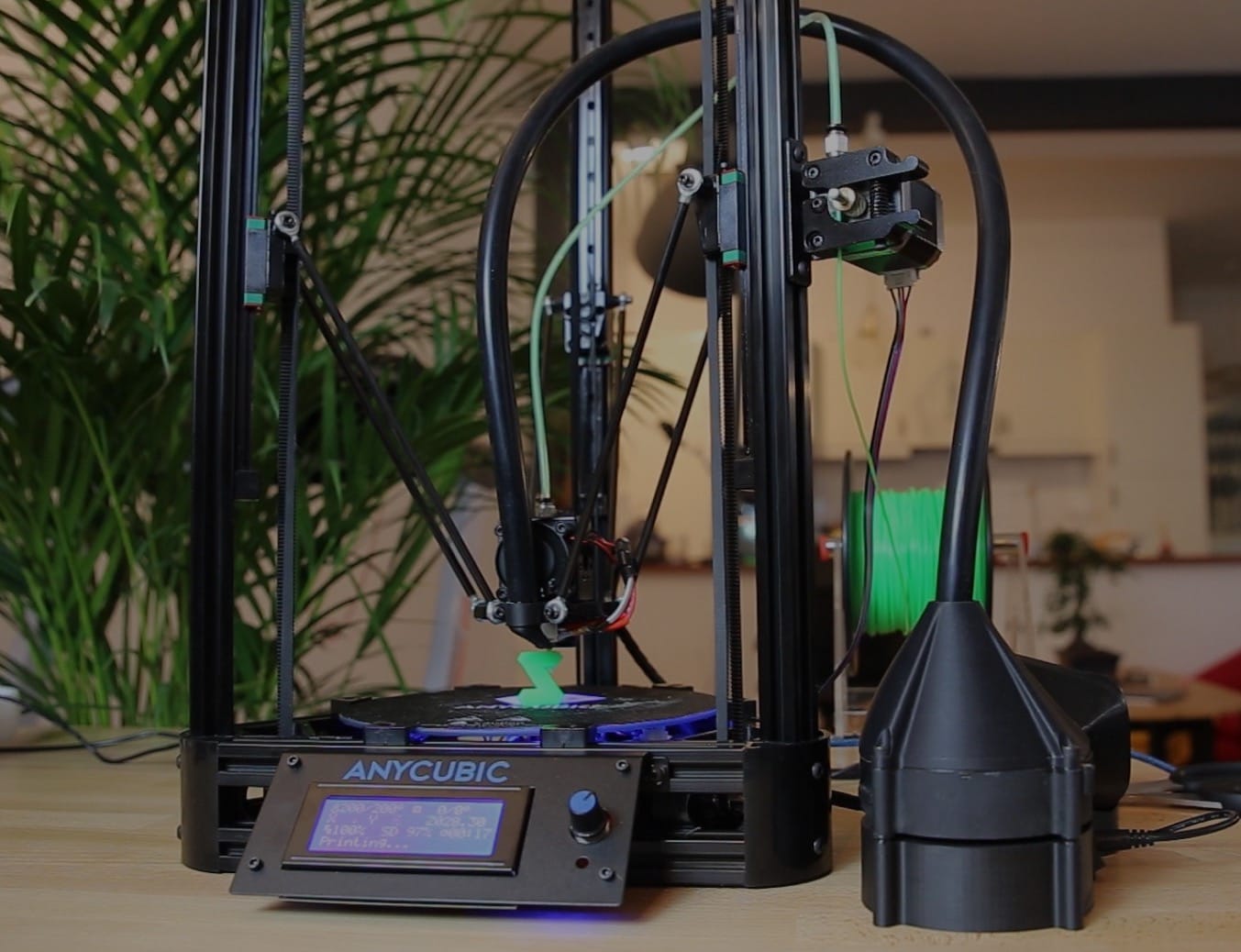

Made by two young French entrepreneurs, the Zimpure is a small accessory that bolts onto your extruder, the source of emissions. A channel takes air flow into the base unit, where it runs through two filters: an ultrafine particle filter and an activated carbon cartridge.

These two filters will remove most of the nanoparticles as well as potentially toxic fumes. Zimple, the company behind Zimpure, says that 98.2% of the styrene and ethylbenzene are removed, for example, and that is certainly something anyone would want.

They explain how it works:

Zimpure is compatible with all your 3D printers. You just have to choose the right suction head, depending on your printer. The pipe is fastened directly to your extruder by a clipping system, by screws or by velcro straps, depending on your printer. The suction flow is put as close as possible of the nozzle.

They’ve currently designed suction heads for a number of popular desktop 3D printers, including: Zortrax, Ultimaker, FlashForge, MakerBot, Delta, Prusa and M3D Micro, and I suspect they will make more on request.

The system’s filters can be swapped out as they are consumed, and Zimple does provide replacements.

This configuration may be more effective than a full size room ventilation system, as it localizes the source of the emissions quite directly. And it’s quite inexpensive as well, priced at only €119 (USD$138).

If you’re looking for an inexpensive and portable 3D print filtration system, this might be it.