It seems that electroplating might become a popular secondary 3D print service, if trends carry forward.

If I see something once, it’s a thing. Twice, it’s interesting. Three or more times and it could be a trend. And that’s where I believe electroplating is headed in the 3D print world.

The idea of electroplating is not new, but here’s how it works:

- 3D print a part in typical plastic 3D print material

- Electroplate the surface of the part with a metal, such as copper or nickel; others are also possible

The resulting plated part is now quite different from its original plastic state. It is now watertight, possibly electrically conductive, resistant to many chemicals, resistant to UV and moisture exposure, significantly stronger and probably has a more attractive surface finish.

This is quite desirable in cases where you don’t need the full strength of a metal part, but do need some of the other engineering properties, as the production of the electroplated “metal” part is significantly less expensive than 3D printing the same print on a proper 3D metal printer. If that’s all you need, then save some cash.

These plated parts do have all those properties mentioned above, but there is one challenge: heat. If they are heated beyond the softening temperature of the interior plastic, then you could have a problem with reduced strength. The plating on the exterior surface won’t melt, but the inner strength is lost. So you cannot use electroplated parts in hot environments.

Two 3D printer vendors I’ve seen demonstrating this approach recently were Roboze and Union Tech, both of whom are experimenting with electroplated plastic parts.

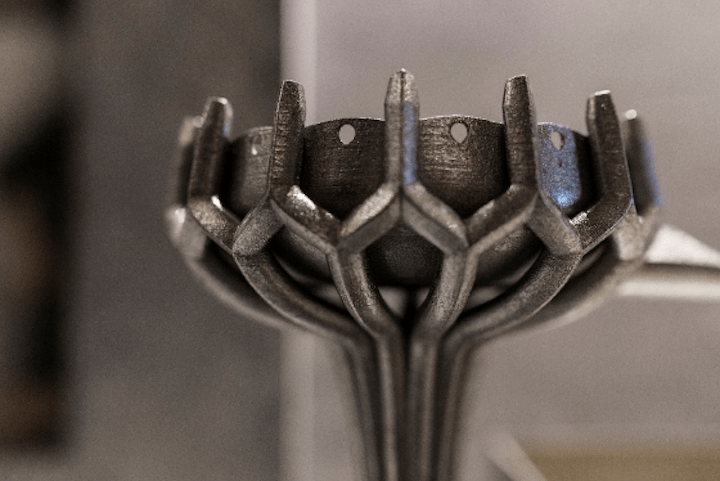

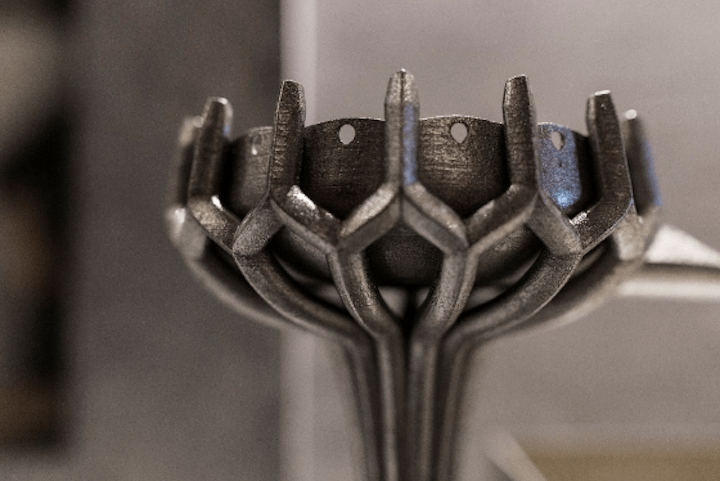

Now I see a 3D print provider offering this as a feature capability: FIT AG of Germany has added a nickel and copper electroplating service for plastic parts. They say the resulting parts will have up to 10x the mechanical rigidity of the non-plated equivalent parts.

I expect that electroplating may become a defacto standard offering by many 3D print services in years to come, as it is a peculiar process requiring additional equipment that many who own a 3D printer may not want to operate. It would be far easier to simply order the part through a service and have it electroplated.

In fact, the 3D printer vendors who have been experimenting with electroplating have typically partnered with other firms who specialize in electroplating, suggesting it’s unlikely we will see a 3D printer manufacturer directly provide that service with their equipment.

Via FIT