Today’s desktop 3D printer operators have a huge advantage over those from years before, through the magic of print profiles.

In the early days it was often simply luck that you’d land on the correct print settings, which include flow rate, print speeds, layer size, temperatures and so on. It took much experimentation to gradually identify the best settings through trial and error – and a lot of wasted filament.

Further complicating matters in those days was the fact that most desktop 3D printers were built from kits and this sometimes led to machines with slightly different physical configurations. A typical difference might be that the heating element would be created by winding a wire, but some assemblers might use more or fewer turns, leading to different heating characteristics.

That meant the print settings on one machine might not work as well on another. It was a frustrating time.

Now things are a lot easier, mainly due to two developments.

The first is that most desktop 3D printers are assembled at the factory and are virtually identical, physically. This means that settings perform predictably between units.

The second, and far more important development, is the sharing of standard print settings for different scenarios, known as “Profiles”.

Leading 3D printer manufacturers now often ship associated 3D print management software with a set of included profiles for common – and sometimes not so common – print scenarios.

Aleph Objects ships a customized version of Cura with their equipment, and current it contains no less than 87 different profiles for two dozen different print materials!

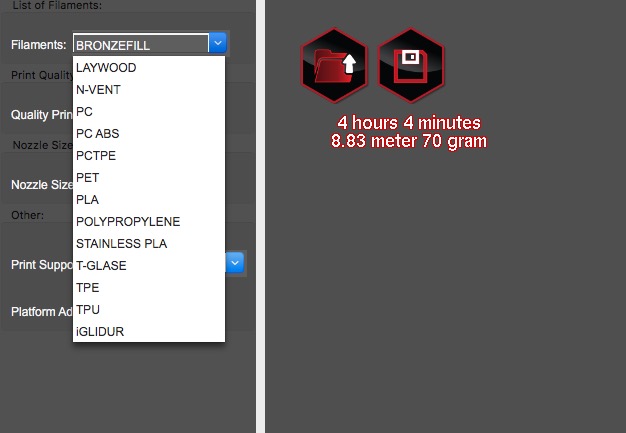

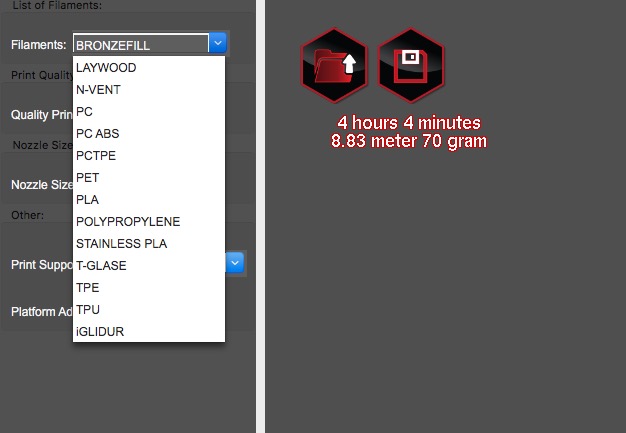

In the screenshot at top, Airwolf 3D’s Apex software includes a number of profiles for popular 3D print filaments, functionality now becoming more common in the professional desktop 3D printing industry.

And those two aren’t the only ones. Many other companies produce similar profile sets, some comprehensive, others less so. Ultimaker is another company providing comprehensive print profiles, recently introducing a number of new profiles for more exotic materials, in particular their new polyproplene filament. And those manufacturers producing proprietary materials often bake the profiles directly into their products – they are there, you just don’t see them as prominently.

The presence and usage of these profiles dramatically increases print quality, because someone else has spent considerable time doing those trial and error experiments on your behalf, and their knowledge is encoded in the profiles.

Does it work? Indeed it does. Here is a #3DBenchy printed on a Prusa i3 MK2, and it is certainly one of the nicest I’ve seen. This was printed with an unmodified profile for PLA material.

That’s the kind of result people seek when 3D printing.

But in some cases, where the material is similar to the profile but not exactly the same, the standard profiles are not quite perfect. That’s ok, because the required tweaking is more easily done because the standard profile will be close.

For example, if you’re using a flexible filament from vendor A, but you have only a profile for vendor B’s flexible filament, just start with the B profile and tweak until it works. It will save you time – not as much as if it was the identical filament, but still a saving nonetheless.

The use of profiles is also being driven by the growing professional user market, where engineers and designers are running desktop 3D printers for prototype development. They want to spend their machines’ time producing those prototypes, not testing print parameters.

Where is this going? I suspect that a good set of print profiles will gradually become a defacto standard for open filament machines in the near future. In other words, if a vendor hopes to sell their machine, especially to professionals, they’d better start testing filaments.