Wax 3D printing is a specialty focus within the world of 3D printing and now there’s a powerful new 3D printer for wax casting applications.

Wax 3D printers are used for only one purpose: metal casting. No one actually wants a wax print, it’s too weak and vulnerable to even the most modest heat levels. No, instead wax prints are used as positive molds for metal casting.

The lost-wax process is used, in which the wax positive print is immersed in a ceramic-style material, which is then solidified. It’s then placed in a furnace where the wax burns out completely, leaving a void in the precise shape of the print. This then becomes the negative mold for pouring in liquid metal for casting.

Vertical applications include dental and jewelry, but Solidscape’s new machine is focused instead on the production of highly detailed metal parts.

The S500’s 3D printing process is unique – and proprietary. Two stages take place in the printing process.

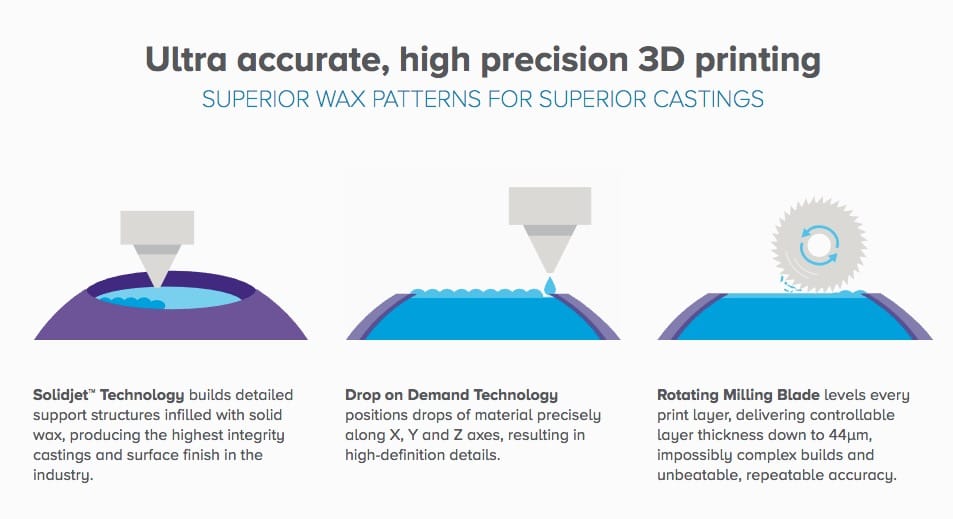

The first stage is to deposit drops of liquid wax in precision form. Solidscape indicates their print head can place drops selectively at a resolution of 5,000 x 5,000 dpi, or about 0.200mm per drop.

The second stage is highly unusual and involves a “Rotating Milling Blade”. Apparently this blade travels across the surface of the most recently applied layer and smooths it to a uniform surface of selectable thickness.

Solidscape says the milling process can produce layers as small as 0.006mm, which is crazy small! This means that the height of the 0.200mm layer drops doesn’t really matter, as the mill will slice it off at the height you want. In this way the S500 can produce high precision wax prints.

Solidscape (which, by the way, is owned by Stratasys) has chosen not to publish a specification sheet for the S500, so I cannot say what its build volume might be. However, it is likely not very large as compared to other machines as is typical for wax and high precision machines.

In addition to the S500, Solidscape also announced the availability of two new materials to go with the machine: a casting material they call “Midas” (get the gold casting connection there?) It is, as you might suspect, designed for jewelry casting.

The company also announced a dissolvable support material, Melt-I, which will enable the S500 to print highly complex geometries where overhangs require support structures. This non-toxic material is easily dissolved after 3D printing.

There’s no word on pricing for the S500, so if you are interested, you had best contact Solidscape directly.

Via Solidscape