3D scanners have never been as available as they are today, but what are the ways they can be used for 3D printing?

The several types of 3D scanning approaches range considerably in capability – and cost. At the low end we have optical-based systems that simply take images, perhaps from a mobile phone, with software to convert them into a usable 3D model, often at no charge.

At the other end there are six-figure devices capable of capturing large objects in requisite detail instantaneously.

In between are a range of tabletop, handheld and drone-driven 3D scanning options. But what are the practical ways people and businesses are using them today?

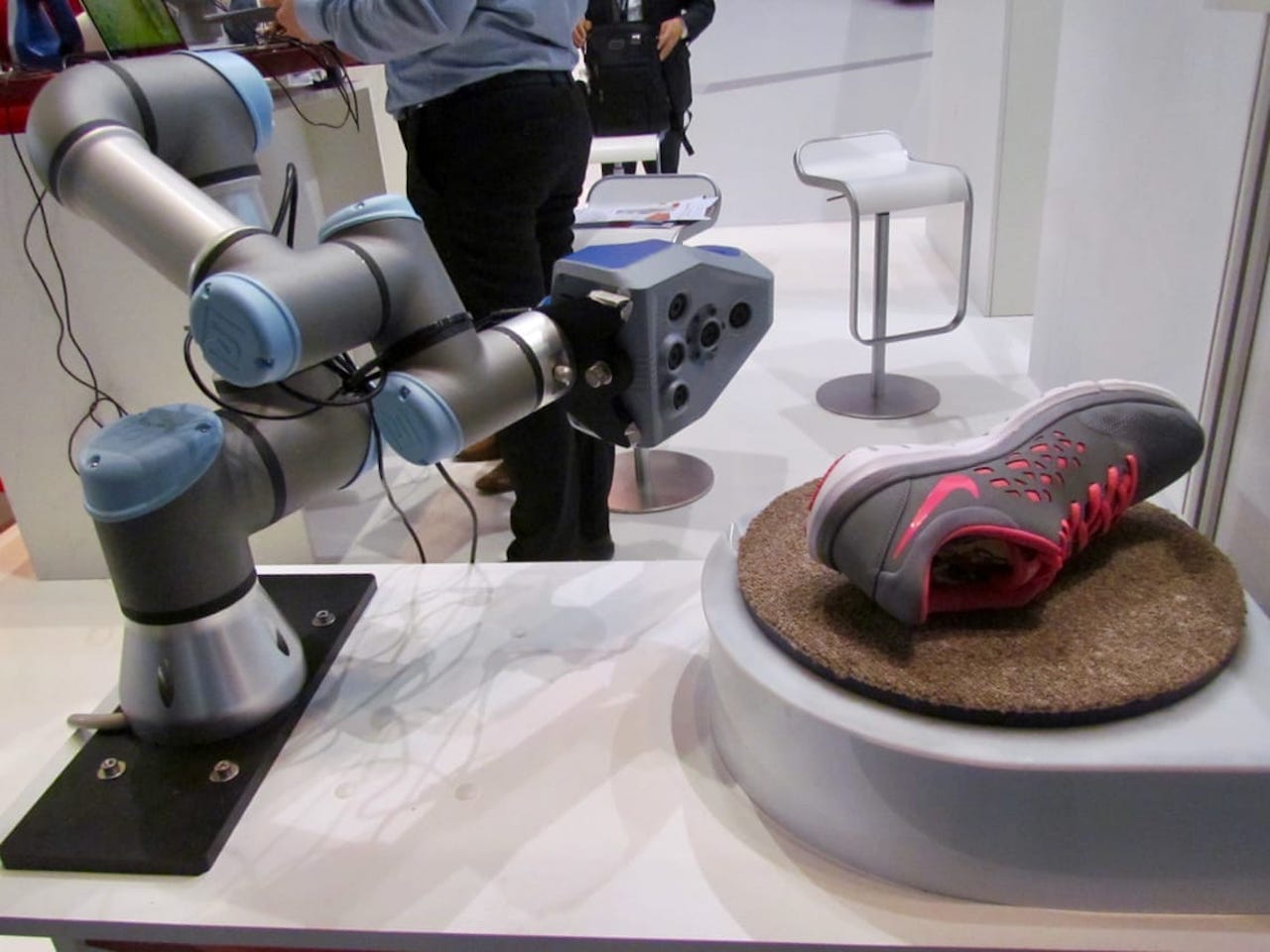

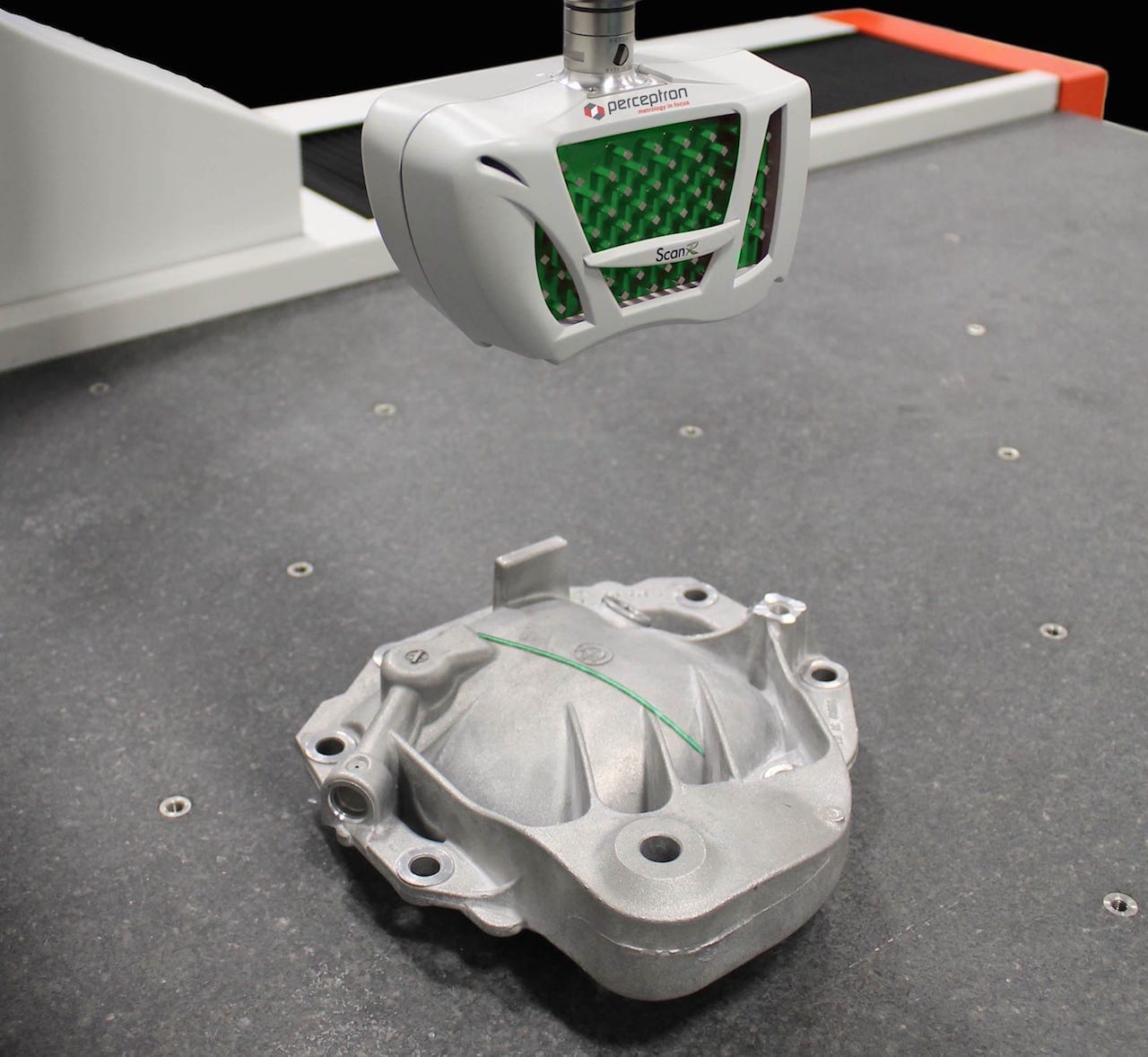

Quality Control: Manufacturing frequently requires an assurance that the parts being produced are within specified tolerances. While there are many ways of ensuring quality parts are delivered, one way is to perform a 3D scan of a 3D printed part immediately after it has been produced. If the scan of the printed part matches (or is at least within required tolerances), then it could be considered a good part.

This technique may not work on all parts, however, as some object geometries are such that a 3D scanner may not be able to “see” internal structures that might be critical to part quality.

Part Restoration: There are times when a part is required, but there is no 3D model. This frequently occurs when dealing with ancient machinery that is no longer supported; the originating company may even be out of business, and there is no where to seek replacement parts. A very typical scenario is repairing older vehicles.

Often a representative part or portion thereof may be available. Imagine, for example, a boat propeller that has only half of its blades. In this situation the remaining blades could be 3D scanned and their shape replicated digitally to restore the missing blades.

Reverse Engineering: There are times when a part exists but it is not clear why it is designed as it exists. It may be possible to 3D scan the object in order to disassemble it into components for deeper analysis. That analysis may reveal why the design went in a particular direction, and also how it might be improved.

Of course, sometimes parts might be reverse engineered by a competitor in order to catch up on a leading product, but this can also happen within a large company that does not fully understand its own parts inventory, particularly for older parts.

Measurement: There are many cases where a new part is required to fit onto an existing part. One way to ensure the new part fits properly is to 3D scan the mounting position to create a kind of negative 3D model from which the new part’s positive shape can be developed.

Site Mapping: Drones have revolutionized how existing large structures can be captured in 3D. Since optical methods have been refined for 3D scan use at lesser scales, there is no reason it cannot also work by having drones orbit structures and capture images in a similar manner.

Medical Preparation: Certain surgical procedures are quite complex and require significant planning to ensure success. Sometimes the planning process is aided by 3D scanning the internal structures of the subject’s body and 3D printing them. The surgeon can then get more familiar with the subject’s structures even before surgery commences.

Personal figurines: There are few things more personal to 3D print than – a person! But in order to obtain a 3D model of a person, face or body, you must engage a 3D scanner of some form. While some opt for the inexpensive route, more complex and detailed 3D scans can be obtained with better 3D scanning gear.

Object Duplication: Sometimes you simply need to duplicate an object, and depending on the specific object geometry and function, you might be able to do for basic objects, such as clamps, jigs and knobs. Scan and 3D print.

Did I miss any?