If you haven’t heard of Multiphoton Optics, you will soon, as the German company has developed a very powerful 3D printing process that is quite unlike others.

Most 3D printing processes are organized around a planar approach, in which objects are built by creating successive layers. The exception is deposition-style robotic systems, which are expensive and rare in the space.

But Multiphoton Optics uses a very different process that offers a very different build process.

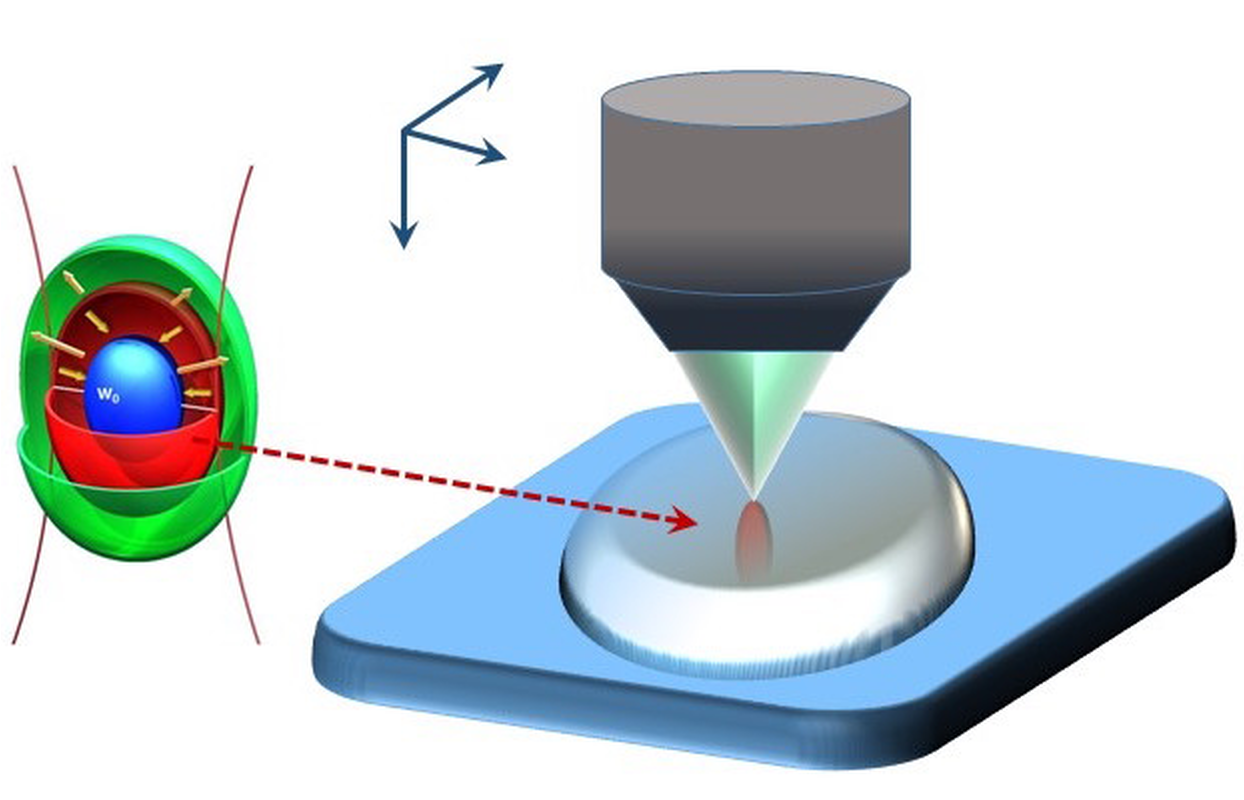

It’s laser based and relies on the concept of a focal point. A laser beam is arranged through complex lenses to converge to a very small focal point. Outside of this focal point, the power per area of the laser is significantly reduced. But at the focal point, there is sufficient power to do interesting things.

Things like solidifying photo-curable 3D printer resin, for example.

Imagine a build chamber filled with a transparent photosensitive liquid material. Now imagine a motion system that moves the powerful focal point throughout the 3D space of the build chamber, lighting up the laser selectively. You are able to “draw” a solid object in 3D form. Imagine a curved, 3D path traversed by a focal point; this would become a solid volume in this process.

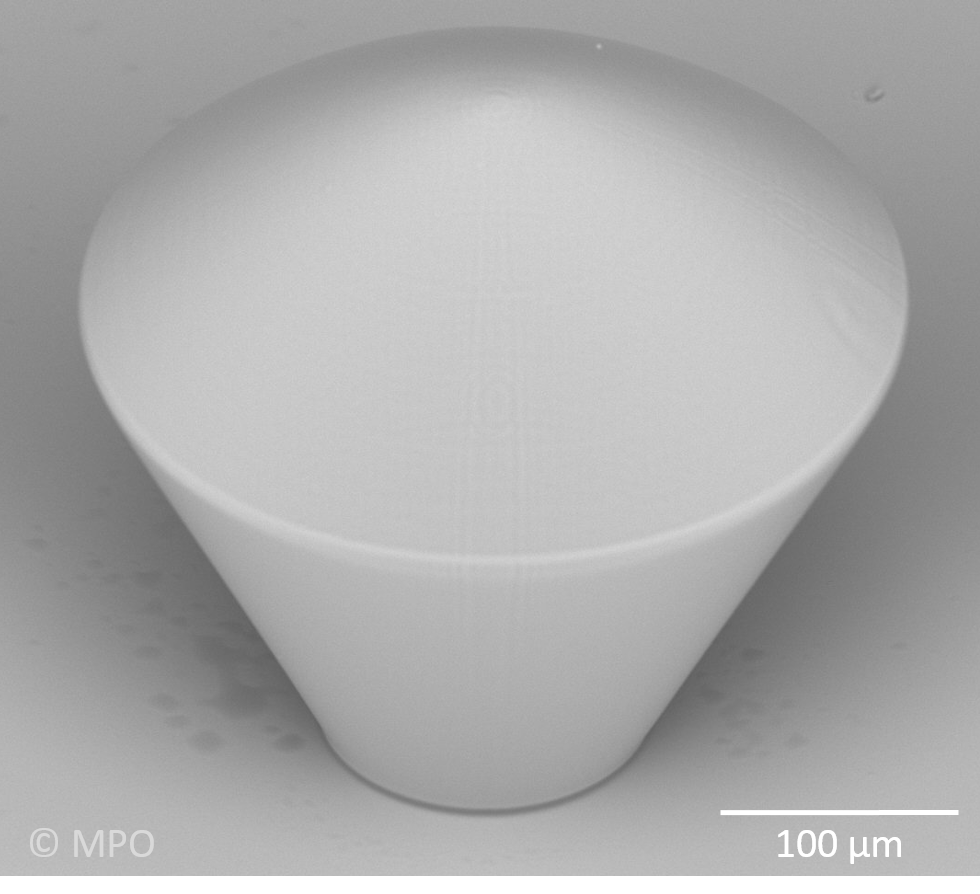

This is the core of Multiphoton Optics: a very different 3D printing process, and there are a number of advantages, the key being incredible resolution, as this is governed largely by the size of the laser focal point.

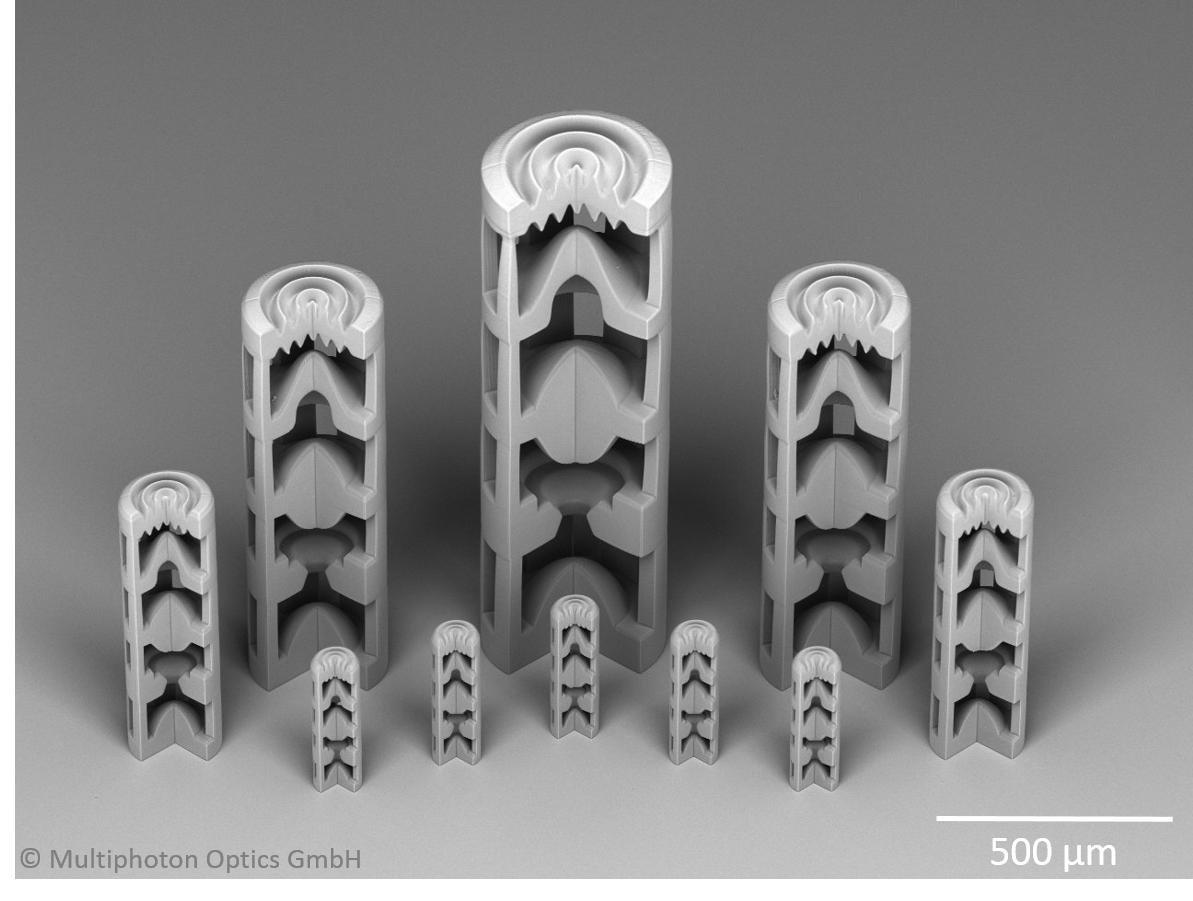

How fine can the resolution be? Mulitiphoton Optics informs us that they can achieve 5-30nm. Just to be very clear, that’s nanometers – not microns! In millimeters this is 0.000005 to 0.000030, one of the finest resolutions I’ve ever encountered in 3D printing, many times greater than any SLA machine could achieve.

But other advantages are present: we’re told that support structures are not necessary in this process. And, due to the extreme resolution, post-print finishing is sometimes not required, either.

This enables operators to achieve direct 3D prints of very sophisticated objects more rapidly than with other 3D printing processes. In fact, the Multiphoton Optics machines are most frequently used to 3D print optical quality lenses, as shown here.

The Multiphoton Optics process operates, as you might guess, at ambient temperatures. This avoids the complexities of heating and cooling frequently seen in other 3D print processes. The solidification occurs due to the use of organic photopolymers that react when exposed to the laser’s focal point.

I should mention that these organic photopolymers are not a proprietary product of Multiphoton Optics; they are actually commercially available products found from many sources.

Currently Multiphoton Optics is using a photosensitive glass material, but we’re told they are experimenting with a metal printing next, which would use a mixture of polymer and metal particles, much like some other vendors have used. If they succeed, their equipment would then join the growing cadre of nontraditional 3D metal printers, including Desktop Metal.

You might be wondering about the speed of this 3D printing process: if the focal point is very small, then it could take a very long time to traverse all voxels in a 3D model, wouldn’t it?

That could be true, but Multiphoton Optics has a solution for this dilemma: adjusting the size of the focal point. It seems that they can dynamically change the focal point to a larger size, enabling “coarse printing”. This would, for example, be done on the interior solid portions of a 3D model. Then a finer focal point could be used to touch up the details on the exterior surface. Brilliant!

Nevertheless, we’re told the print speed of the process is still a bit slower than traditional 3D printers, which would mean slow. However, we’re also told they are working hard to speed up the process and we may see improvements in the future.

And certainly the build volume of their current equipment is not particularly large. However, parts with such fine detail requirements are typically not large in any case.

There’s another interesting aspect of this process: it also works on solid materials. If you were to place a solid object within the build chamber, you could certainly move the focal point to the surface of the object, applying arbitrary levels of laser power. In this way the same device can be used for ablative manufacturing. This could be used to apply a pattern or label to the surface, applying a treatment of some kind or possibly cutting into the surface depending on the nature of the material.

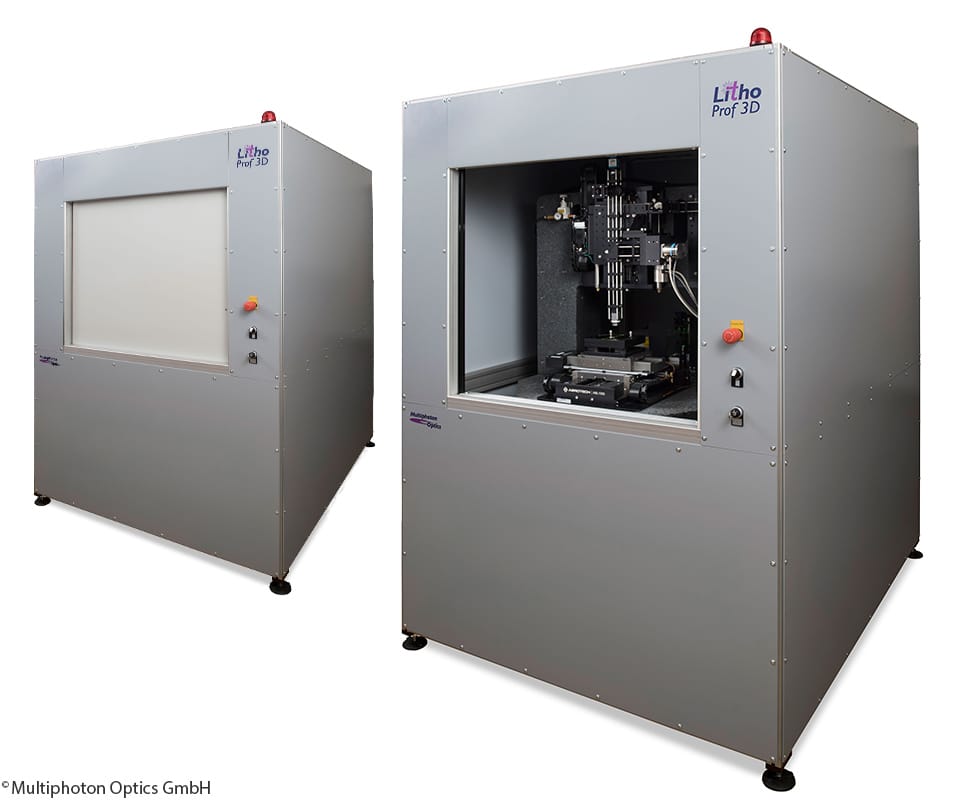

The four-year-old company presently offers a number of prototyping and engineering services related to the process, and can 3D print parts on request. They also offer the machine itself, the LithoProf3D, for purchase if clients expect frequent use. However, this is not an inexpensive unit, being priced in the €500-550K (USD$580-640K) range. We’re told they are working on a smaller unit for around €350K (USD$410K) to be released at an unknown future date. Thus far Multiphoton Optics has sold a number of units worldwide to “very well known companies”.

Multiphoton Optics appears to be well-funded, having gone through several investment rounds and now having a staff near 15 people. It seems they will be around for a while – and that’s a good thing.