Fiberlogy is a Polish company producing high quality 3D printer filaments, and we had the chance to test not one, but four of their materials.

We obtained 1kg spools of their HD PLA, Fiberwood, Fiberflex 40D and PLA Mineral filaments for live testing. The company also sells ABS, HIPS and something called “Easy PLA”, which, as you might expect, is designed for an easier 3D printing experience.

Fiberlogy touts their filament quality, saying:

Our materials have outstanding properties and parameters – diameter tolerance of +/- 0.02mm and oval tolerance of +0.01mm. This allows for high precision printing and an ever wider use of 3D printing technology.

And this indeed seems to be the case. In all our prints, we never encountered a jam or print failure, although we did have to iteratively experiment with settings to obtain the best results.

HD PLA

Our spool of black HD PLA lived up to billing, producing strong prints, although not as tough as ABS. Of course being PLA, this material is not as heat resistant as ABS. You should use parts printed in HD PLA only in moderate temperature environments.

While many companies now offer similar high-performance PLA filaments, Fiberlogy’s version is certainly as good as any of them. Recommended.

Fiberwood

The Fiberwood material is, like other wood filaments, a careful mix of wood fibers and PLA plastic. As such, it prints more or less like PLA, in similar temperature ranges.

The prints do appear wood-like, although they are clearly not wood. During printing they do exhibit a very slight wood-like smell.

Surface quality on wood prints always seemed a bit rough, although I believe that’s actually a feature for this material: Wooden items should be slightly rough. Certainly you can sand prints down to a smooth appearance if required. Fiberwood prints were quite strong unless printed in very thin structures.

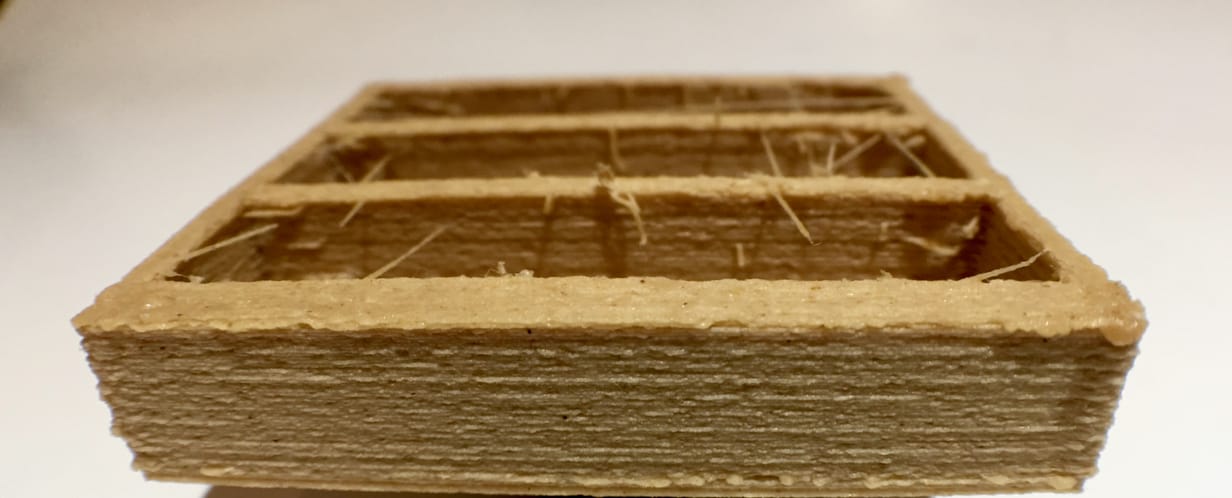

We found the Fiberwood material to be a bit runny, regardless of temperature used. Our hot end frequently dribbled out Fiberwood material, particularly at the end of a print, where there was always a very long strand connecting the distant hot end to the top of the print, as shown here.

This runny quality also generated strings during non-contiguous printing jumps. We attempted to minimize them by increasing the retraction settings, even up to a huge 4mm, but we never could completely eliminate them. However, they were quite easy to remove once the print completes.

Here you can see our progress in gradually removing the strings by a combination of temperature adjustments and increased retraction settings.

Fiberwood sticks very well to cold beds equipped with a suitable PLA-compatible adhesion surface. We found the material sticks more than sufficiently during printing, yet is easily bonked off after the print completes. On hot surfaces, it should work equally well.

We recommend using Fiberwood for projects requiring a wood-like finish, but not for applications requiring smooth surface finishes.

Fiberflex 40D

Like all flexible filaments, Fiberflex 40D is challenging to 3D print. You must use a direct-drive extruder, as a bowden-style extruder would not be able to push the loose filament any significant distance without having it coil up.

Another issue we encountered was adhesion. On a cold bed, even one equipped with a PLA/ABS-compatible adhesion surface, it does not stick very well. You really must use a heated print surface for 3D printing with this flexible material.

We found that you must 3D print very slowly to be successful with Fiberflex 40D. Speeds as low as 10mm/second, or even slower, seemed to work, particularly on shapes requiring only continuous extrusion. Abrupt turns and non-contiguous layers meant slowing things down even more.

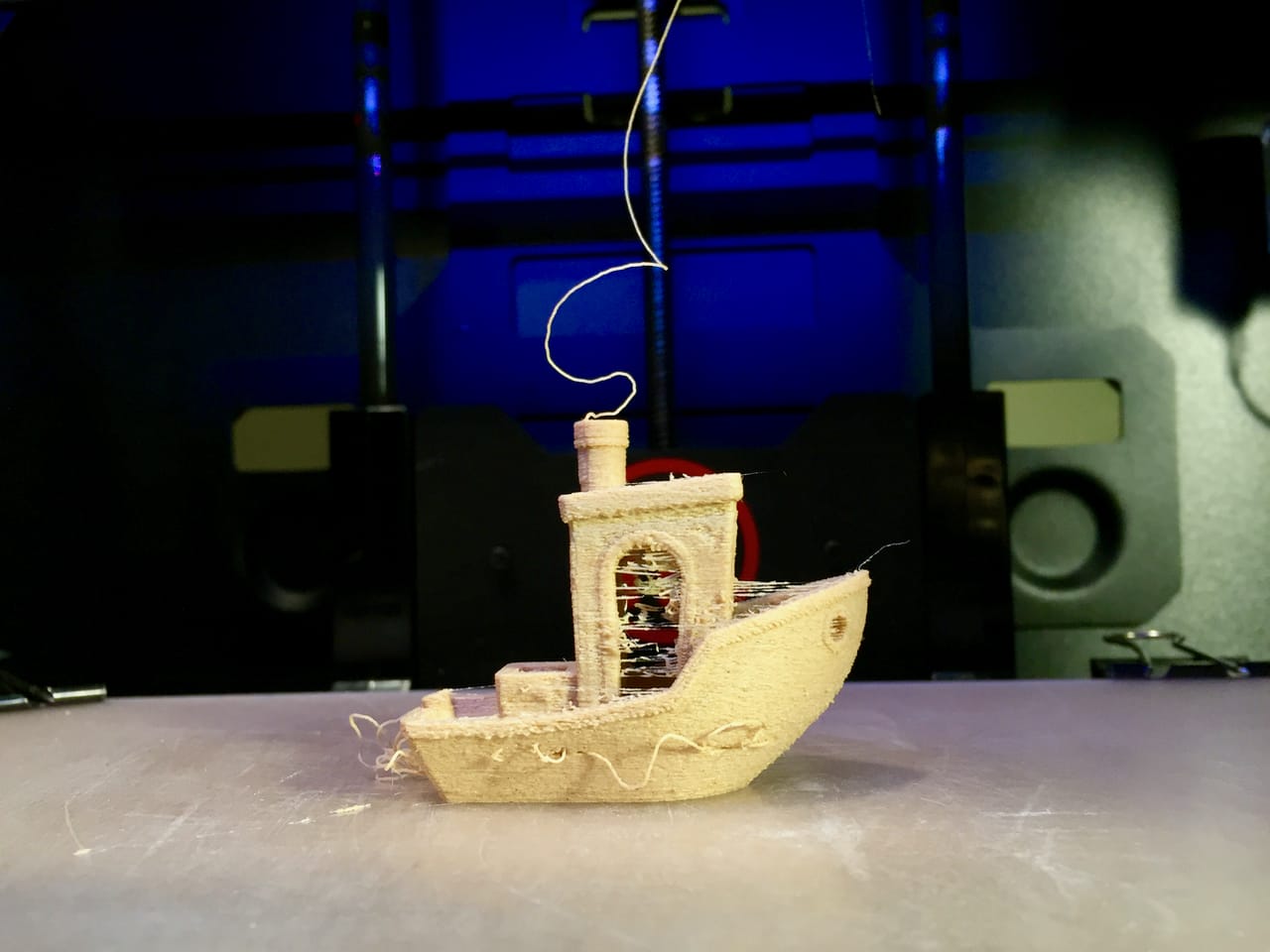

Running Fiberflex at normal print speeds likely won’t be successful, as you may end up with a print that looks something like this.

But if you correctly configure your print settings, there’s another challenge: this stuff tends to stick extremely well to a hot print surface. So well that you might consider putting some painter’s tape down first. We did and it worked out very well.

Flexible materials are great for printing smaller components, like hinges, gaskets and plugs, and we recommend Fiberflex 40D for these purposes.

PLA Mineral

Saving the best for last, Fiberlogy’s PLA Mineral is a fascinating material to print with. It’s definitely not for every application, but for printing figurines and artistic works, it is simply ideal.

The material is a mix of PLA, chalk, and perhaps other powdered stony materials. Whatever the mix, the prints are truly magnificent to look at; Figurines appear like marble statues.

PLA Mineral prints exhibit very fine detail as you can see in these images. The surfaces seem particularly smooth and continuous, in spite of not printing with the finest layer sizes. Perhaps the white color adds to that visible effect, but it does work.

The PLA Mineral prints are also very rigid, almost to the point of fearing they may shatter if you were to drop one on the floor. But once again, that adds to the impression that this is “mineral”.

I encountered one issue with this material: adhesion. No, it’s not that it’s hard to stick down, but instead it’s quite the opposite! PLA Mineral sticks far too well.

My first print on a cold bed with adhesion surface stuck so well I literally could not get the print off without breaking the print. While the print looked very good, it was shattered and left what seemed to be permanently attached bits to my adhesion surface.

I was surprised to find out that these bits could not be removed physically, even with a heat gun; it simply smeared over the surface. The only way I found to remove them was to print some HD PLA on top of them and peel it off. The good news is that the print bed was undamaged through all this activity.

The proper adhesion solution seems to be printing on a heated surface covered, once again, with painter’s tape.

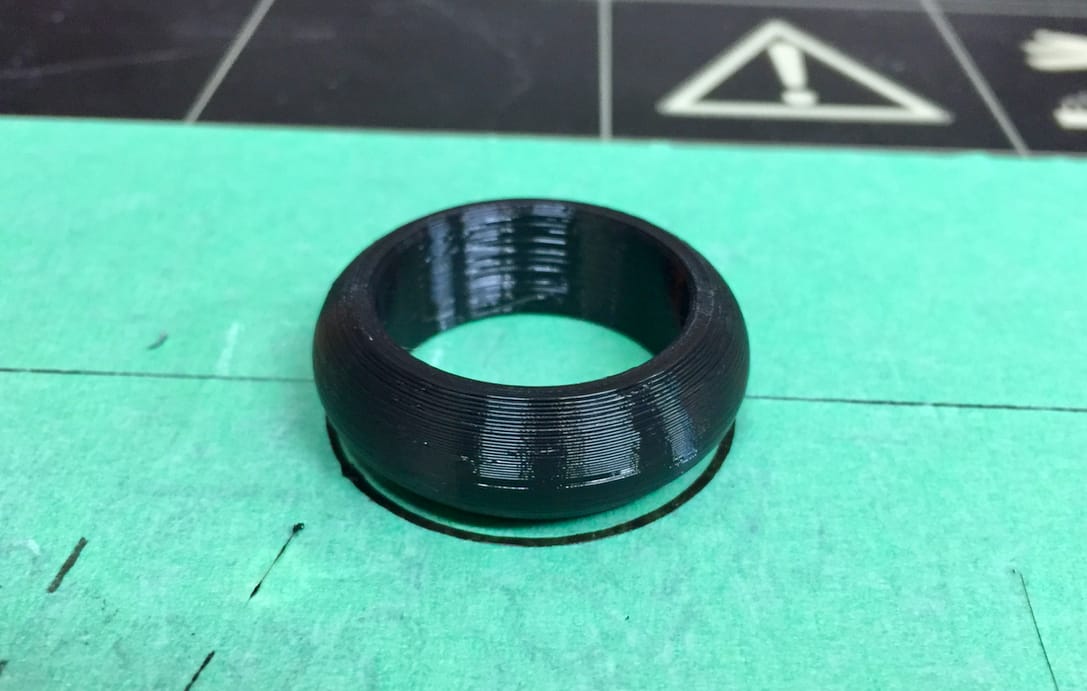

This approach worked very well and results in a straightforward print removal. However, you do end up with some tape on the bottom surface, as shown here. I’d rather have that than a broken print, wouldn’t you?

Availability

Priced at between €35-45 (USD$40-50) per kg, these filaments are not overly expensive, particularly for the quality you’re getting.

While Fiberlogy’s filaments are very good, they are sometimes hard to find. The company, based in Brzezie, Poland, has excellent sales availability in that country, as they rely on a network of resellers. Outside of Poland it’s a bit more rare to find their filaments, but there are several outlets in UK, Denmark, Belgium, France and Finland. Unfortunately there are no outlets in the West at this time.

However, the company is seeking additional resellers and it would be terrific if they could find some partners in North America and elsewhere to broaden their reach. North American filament resellers, you might give these folks a call.

Via Fiberlogy