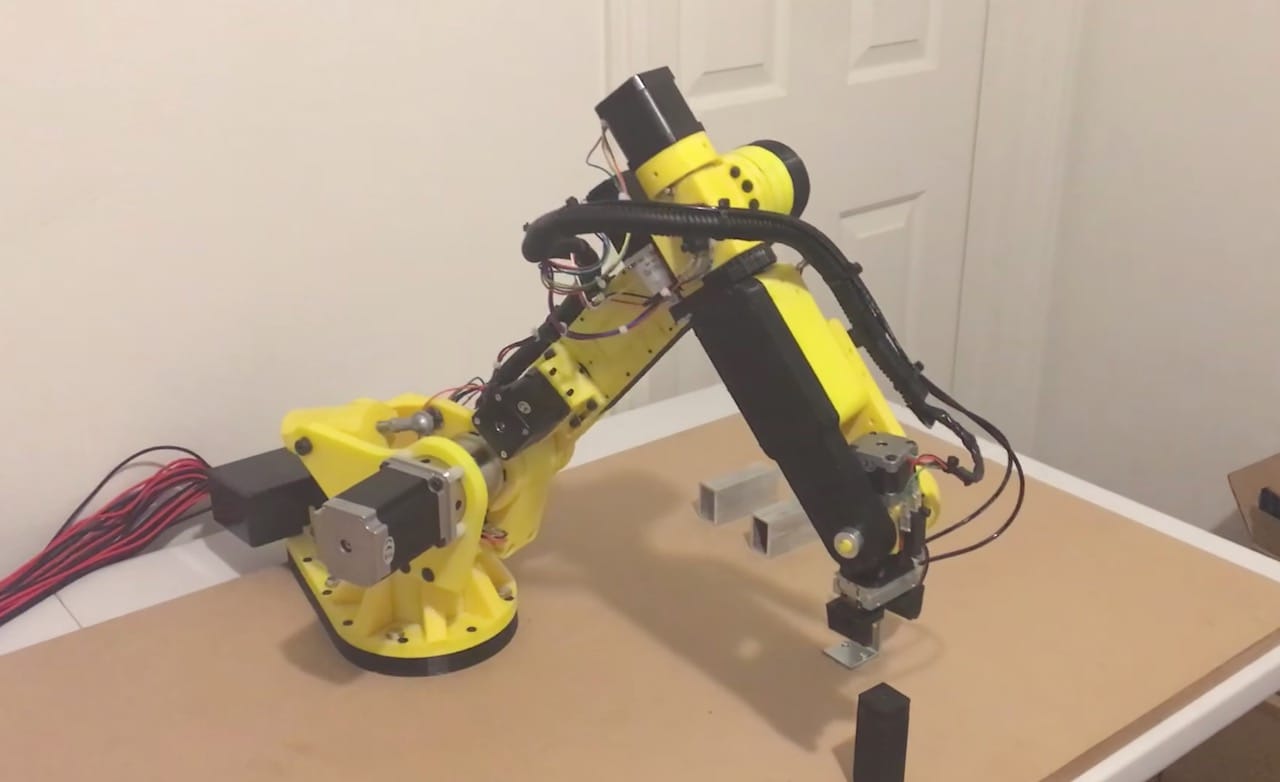

This week’s selection is the complex six axis robot arm by Chris Annin.

This design is not for beginners, as it involves a significant amount of electronics and software installation, as well as the 3D printing.

But if you progress through this project, you will end up with an actual, programmable six-axis robot arm that can do many things. It’s obviously not as capable as a commercial robot arm, which could cost you far more than six digits, whereas this project could cost you around USD$100 for parts.

Annin has carefully selected parts that are commonly available from “Amazon and McMaster”, where they have low pricing. And this is actually a second-generation design, with improvements learned from the first design.

The tremendous amount of work that went into this project has been made public by Annin, who has posted all required files to GitHub, including:

- Bill of materials and instructions

- CAD files to 3D print components to build the robot

- Arduino sketch for stepper driver control

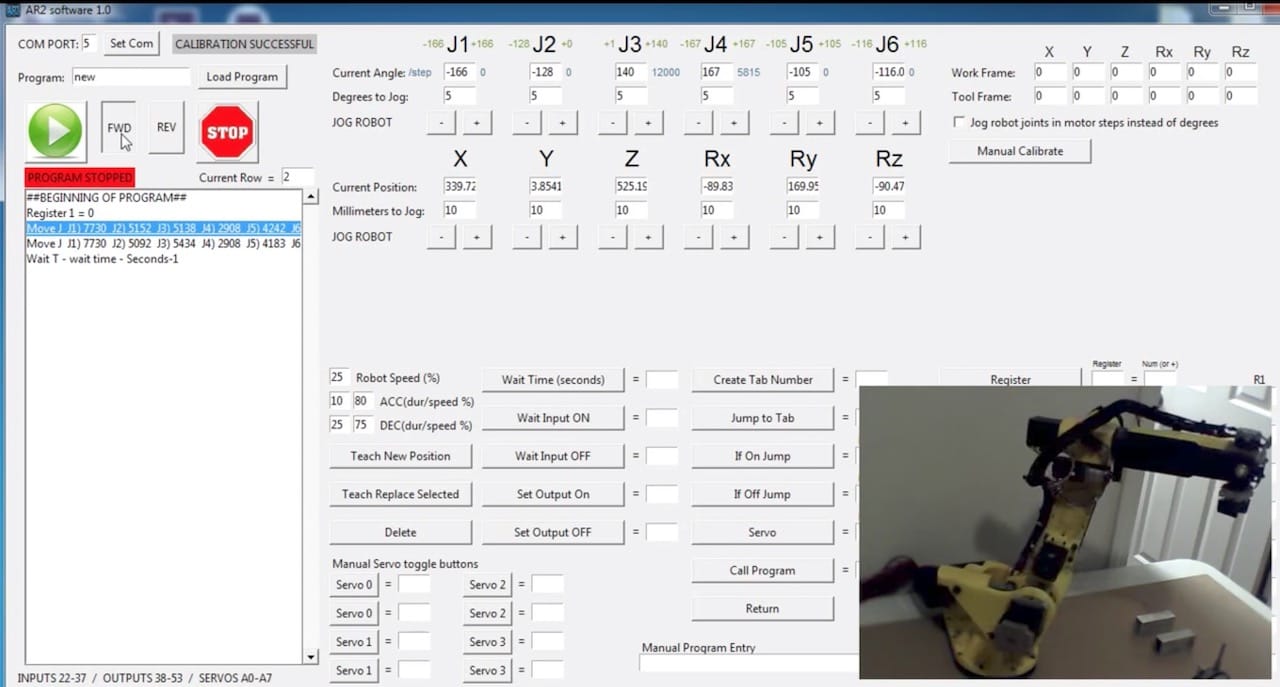

- Software to program and operate robot

- Kinematic model

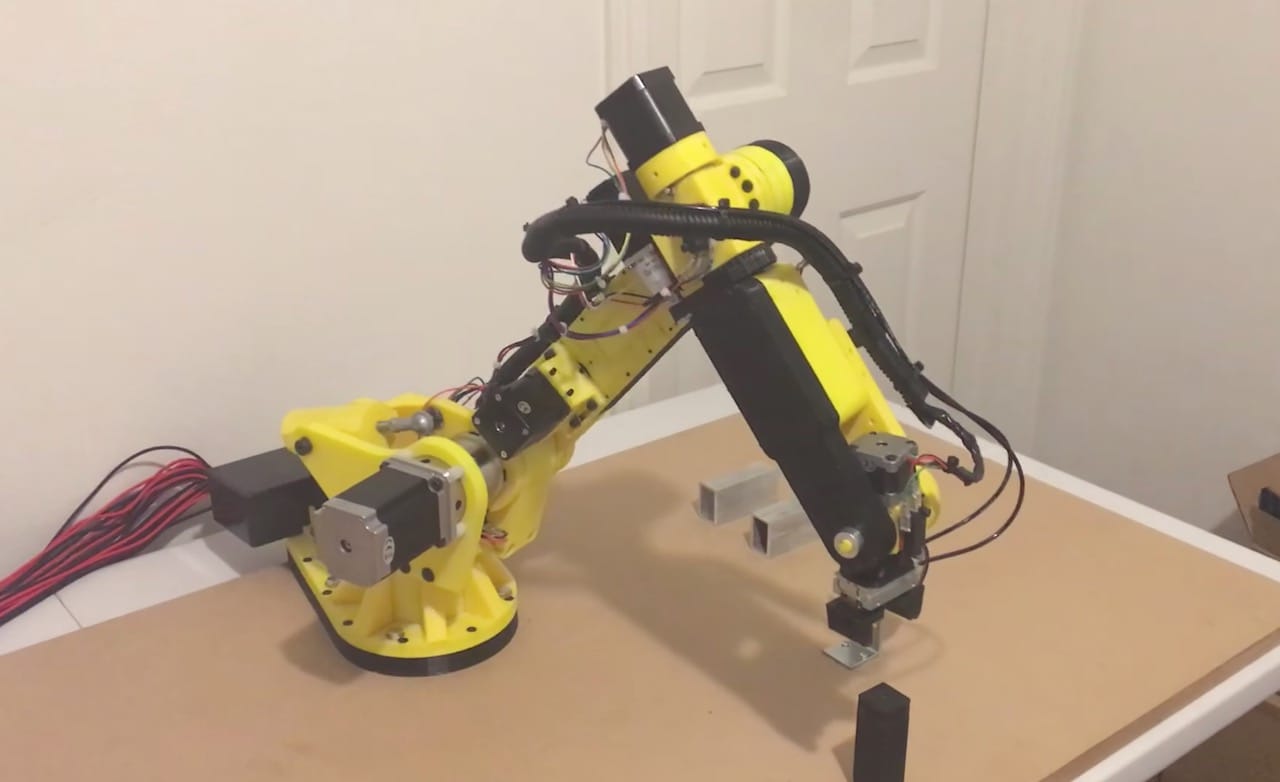

He has also published videos demonstrating the six-axis device, like this one, where you can get a very good idea of how this machine works once you’ve built it:

He has also posted a 20 minute video explaining how to program the six-axis robot arm:

One thing to note is that if you wanted to use this robot arm for milling, for example, you would face a bit of a software challenge, as there are few and pricey options for multi-axis CNC software.

But it would certainly be fun to 3D print and build regardless.

Via GitHub