I’m reading a release from ESA, the European Space Agency, who seem to have found a new way to use 3D prints.

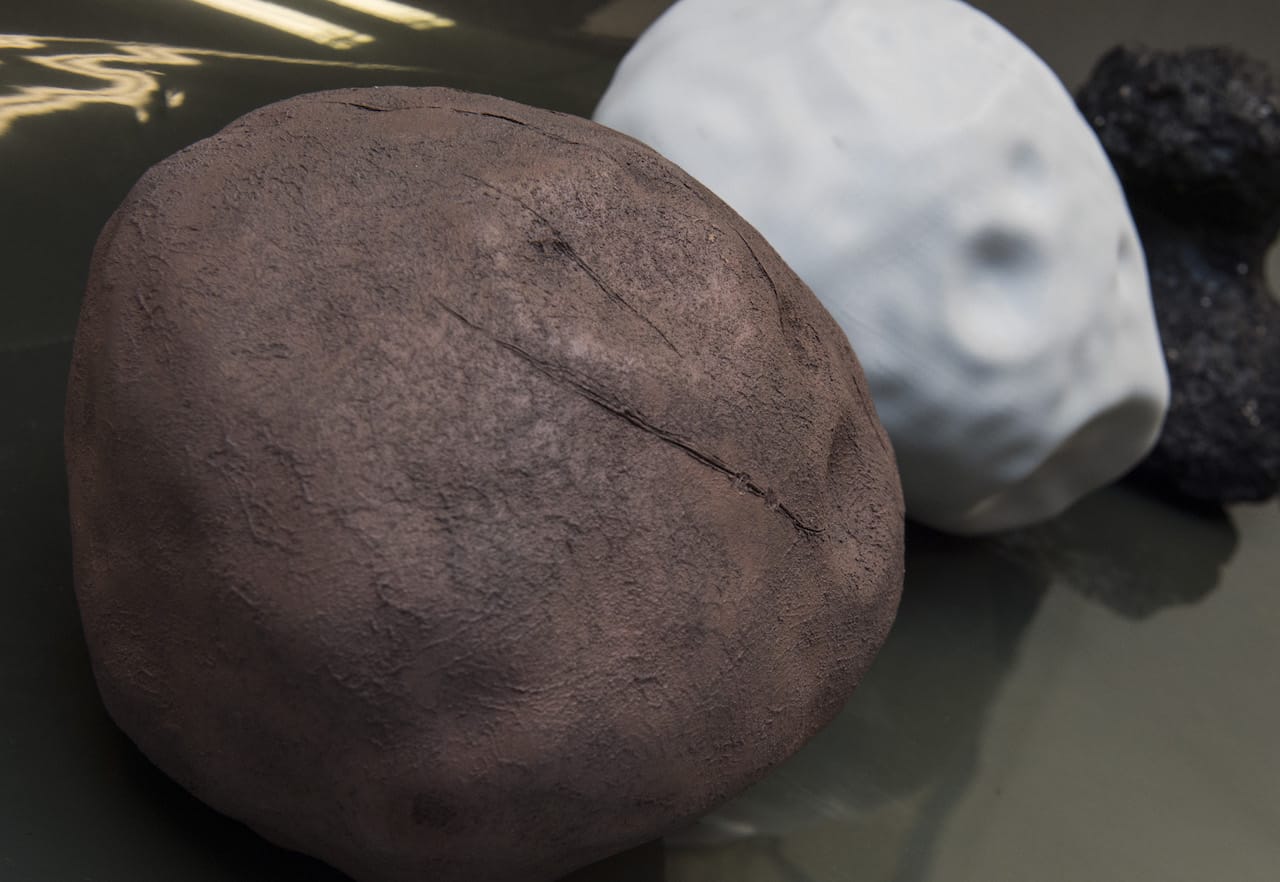

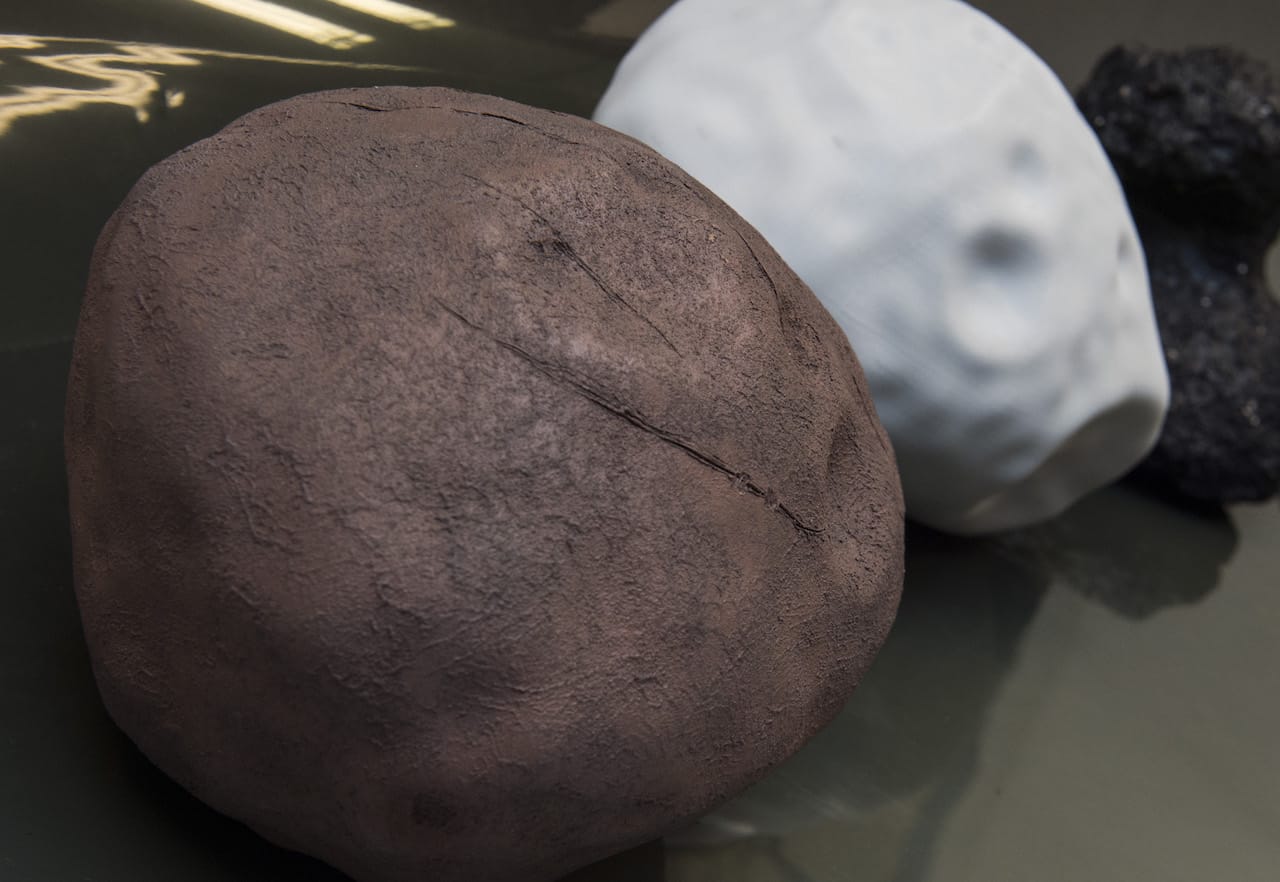

The space agency has been busy 3D printing 3D models of notable asteroids in our solar system. And they’re not just doing this for fun, as there is a real purpose here.

The completed 3D prints are carefully painted to realistically appear as the actual asteroid. It’s then they are used for the new purpose: testing automated navigation systems.

Asteroids are typically very distant from Earth. As there are usually no humans aboard these spacecraft and the radio transmission time can be measured in tens of minutes, the spacecraft must operate autonomously. It must be able to recognize its environment with its sensors and act accordingly.

While the 3D printed asteroids are obviously vastly smaller than the real thing, the camera software sees it as if it were real. And the software is what is being tested here. ESA makes up a mechanical scenario where the camera moves about the 3D printed asteroid in a way that resembles its intended trajectory. Then the camera and software take over and operate independently.

Certainly testing can be done using standard virtual simulations, but this way there are more opportunities to find problems.

In this way they can perhaps ferret out software bugs when they have a chance to repair them, because it can be expensive to send service personnel to rejig a spacecraft somewhere between Mars and Jupiter.

That’s all fine, but is this representative of a new class of applications? Could you, for example, use this same technique for testing and training autonomous vehicle driving systems? What about drones? Could you train a drone to recognize specific object shapes that might appear differently from viewed afar?

I expect there are numerous ways this approach could be leveraged by a number of different industries, not just space exploration.

Via ESA