3D Platform has been developing ways to dramatically speed up 3D printing very large objects, and their latest extruders are simply insane.

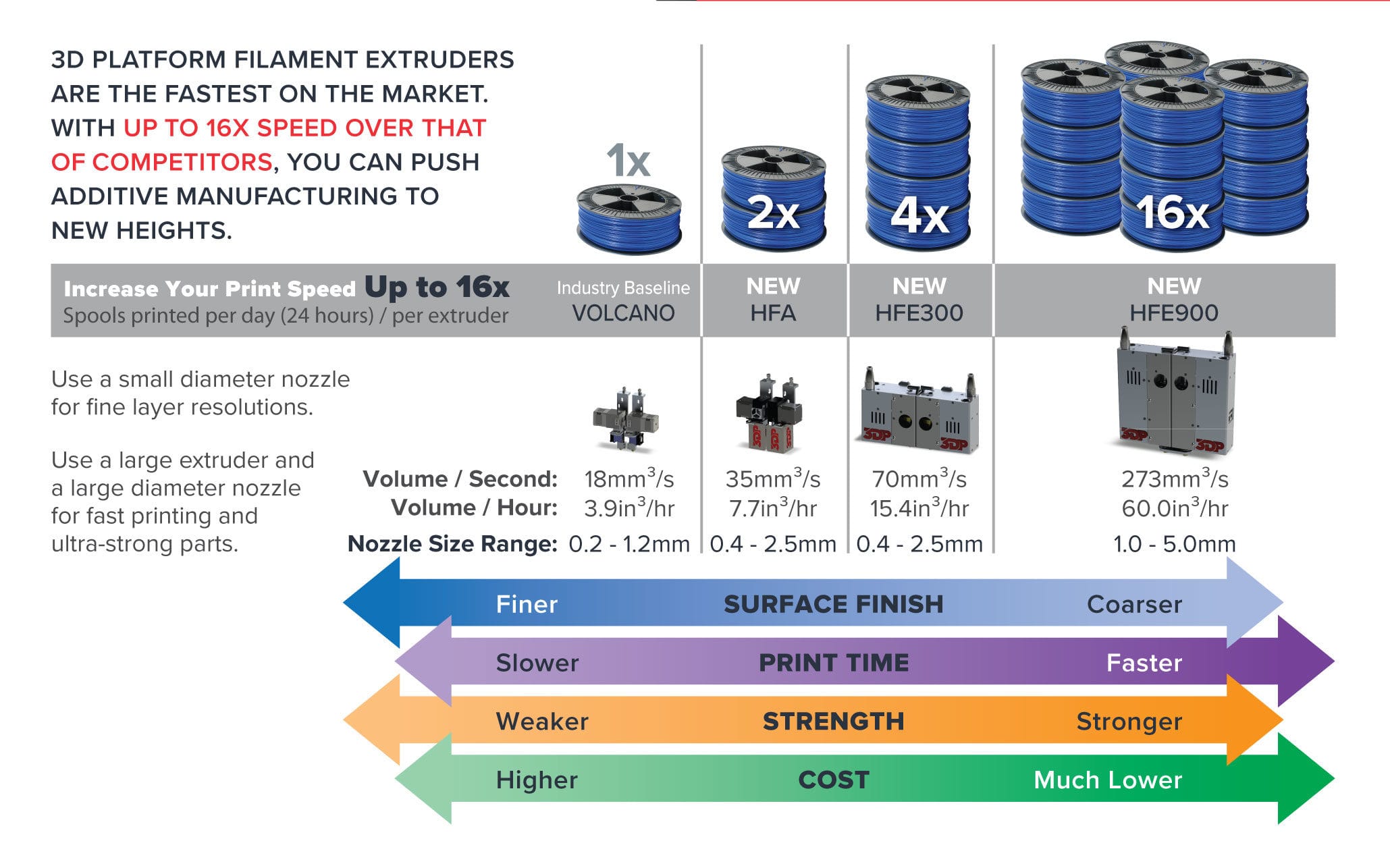

While most 3D printer vendors make tweaks to their extruder design, 3D Platform has developed what are likely to be the highest volume extruders in existence today, their HFE series.

The problem they are solving is the print duration problem on large-scale 3D printing. Early large format 3D printers were essentially scaled up versions of desktop machines, often using identical or similar extrusion systems.

These systems could deliver a few cubic millimeters of material per second. While that’s acceptable for a 3D print the size of your hand, it is unacceptable for 3D prints on large format machines that might be the size of furniture. Or literally BE the furniture.

Their previous high-volume extrusion system, the HFA series, was impressive, but the new HFE series takes things to an entirely new level of 3D printing capacity.

There are three models, as you can see at top, ranging from the “small” HFE 300, up to the massive HFE 900. You’ll note that they each appear quite tall, and there is a reason for this: to print at higher volumes, you must push plastic faster through the system. But that means the plastic would be exposed to heat for a shorter period of time. To compensate, the hot end component is longer, ensuring the plastic is exposed to heat sufficient for softening.

Let’s look at the stats for the HFE 900:

- Extrudes up to 1.35 kg per hour (!)

- Requires 900W input power to heat the rapidly moving plastic

- Accepts 6mm filament, far larger than the more common 2.85mm format

- Has nozzle sizes between 1.0 and 5.0mm, among the largest I’ve heard of

Let’s put this in perspective: on a desktop 3D printer, how long would it take you to 3D print an entire 1kg spool of 1.75mm filament? A week? A few days? Likely that’s the case, assuming you are 3D printing continuously.

There’s another advantage to this: all 3D printers can fail, and the longer the duration of the print job, the higher the probability of failure. By dramatically dropping the print duration, the probability of failure decreases as well.

The HFE 600 can print that entire spool in only 45 minutes.

However, the HFE print would likely be far coarser than you’d receive on the regular desktop 3D printer. This coarseness is quite acceptable for a large format print, however, as your eyeball distance to the print would be much further so you cannot see the larger layer lines anyway.

The HFE extruders are an optional accessory to certain models in 3D Platform’s growing line of large-format 3D printers, and I suspect they should be considered by anyone requiring large 3D prints.

Via 3D Platform