A word you may be hearing more frequently in the world of 3D printing is “isotropic”. Let’s look into what that means and the implications for 3D printing.

Isotropy is defined as “Isotropy is uniformity in all orientations”, and that’s what we’re talking about here.

Imagine an isotropic part, one that is the same in all dimensions. This means that it should look the same from all viewpoints, have the same color, and feel the same on the surface.

But while those are certainly interesting, the property that’s of most interest to 3D print operators is strength. That is to say, the part has equal strength in all directions, at least material-wise.

This is a thing because historically most 3D printers have printed parts in layers, depositing one layer after another.

Let’s examine this a bit. Look at the diagram at top, where you can see several layers extruded on top of one another. This is the typical form of a 3D printed part as produced by a filament-powered 3D printer.

Regardless of how fine the layers were deposited, there are strength characteristics that are very important.

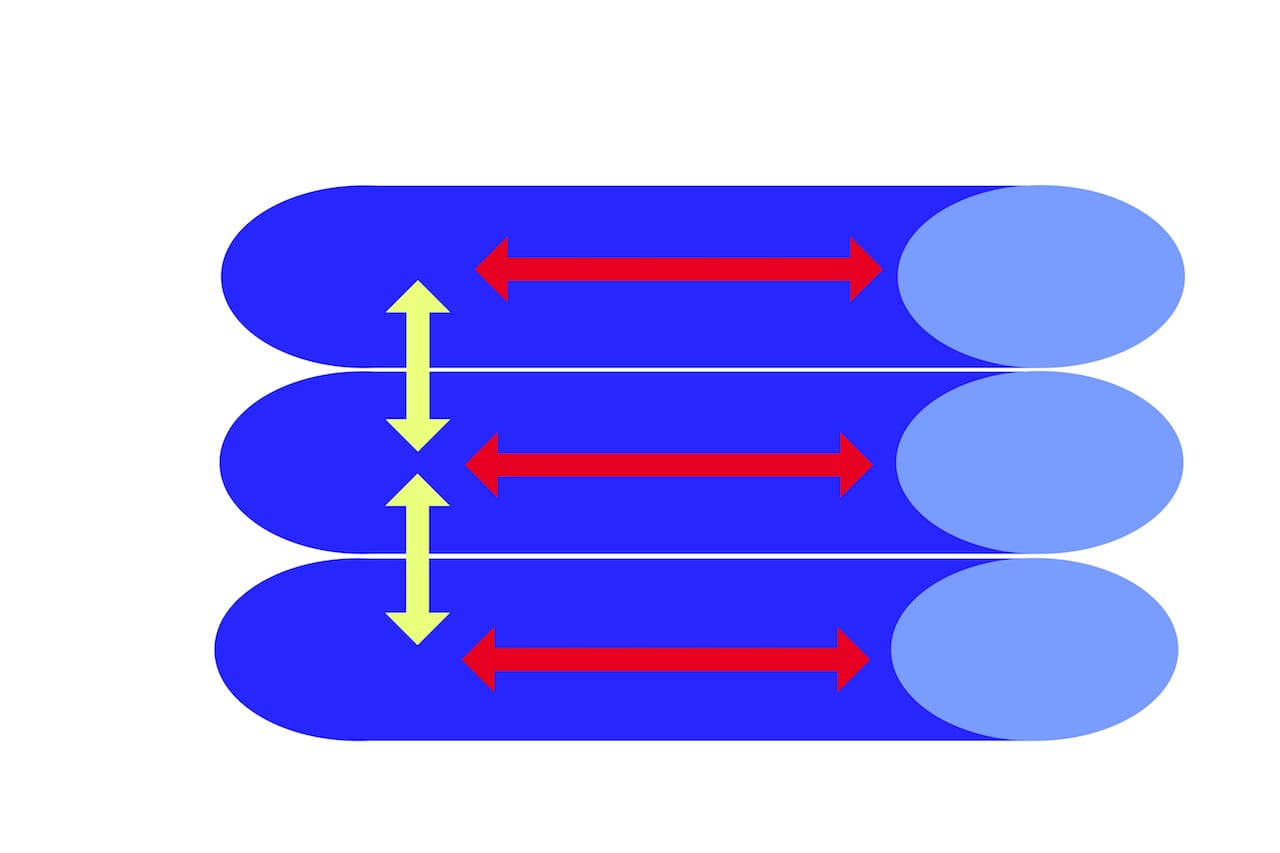

Look at this diagram, which adds some directional arrows.

The red arrows are aligned with the extrusions. Along these lines the strength of the object is essentially the same as the strength of the material itself, as a force along this direction tests the bonds between the material’s molecules, and there are many of them.

Meanwhile, the yellow arrows show a different direction. Here the weakest link is in fact the bond between the layers, which comprises much less material. Fewer molecules, and perhaps bound less uniformly due to deposition of hot material on cold during 3D printing.

What this demonstrates is that the part will break on the yellow axis far sooner than on the red axis.

This isn’t to say that it’s a problem. It’s just one of many constraints one must be concerned with when 3D printing on filament-based machines.

Typically 3D printer operators would rotate a part so that it would be printed with layers matching the required axis of strength.

That often works, unless the part receives mechanical stress from more than one direction, in which case you must choose a compromise strength axis. Sometimes that works, and other times it does not, as it depends on the geometry of the part and the circumstances of its use.

But back to isotropy. An isotropic part, if you could make one in a 3D printer, would eliminate this constraint entirely. You wouldn’t have to worry about which direction it was printed, as the molecular strength would be the same in all directions.

You could then be free to make 3D printed parts that are more functional. An ideal quality for someone using 3D printing for professional design purposes.

So far, the number of 3D printers that claim to make isotropic parts is very low, perhaps because the filament extrusion process makes the production of isotropic parts quite challenging.

But I suspect that isotropy will gradually increase in importance, eventually becoming a de facto default feature in any 3D printer. I think this trend is beginning this year and will continue going forward.

But until then, please continue turning your prints upside down, as required.