It’s been obvious for a while that Stratasys has been focusing very closely on the aerospace industry, and now they’ve announced a significant development.

Aerospace manufacturing is a very tough business to get into, as the parts used on aircraft must all be certified and tracked diligently for the entire lifetime of the part’s use. Replacement parts made, say, ten years from now must meet the same certifications before the part can be used.

The aerospace industry has developed a rigid set of certification processes to achieve this, and it works, although it’s challenging for manufacturers. However, it has not included additive manufacturing aspects. Until now.

Apparently polymer additive manufacturing components are being added to these standards, meaning if a company met them, those 3D printed parts could be legally used on aircraft.

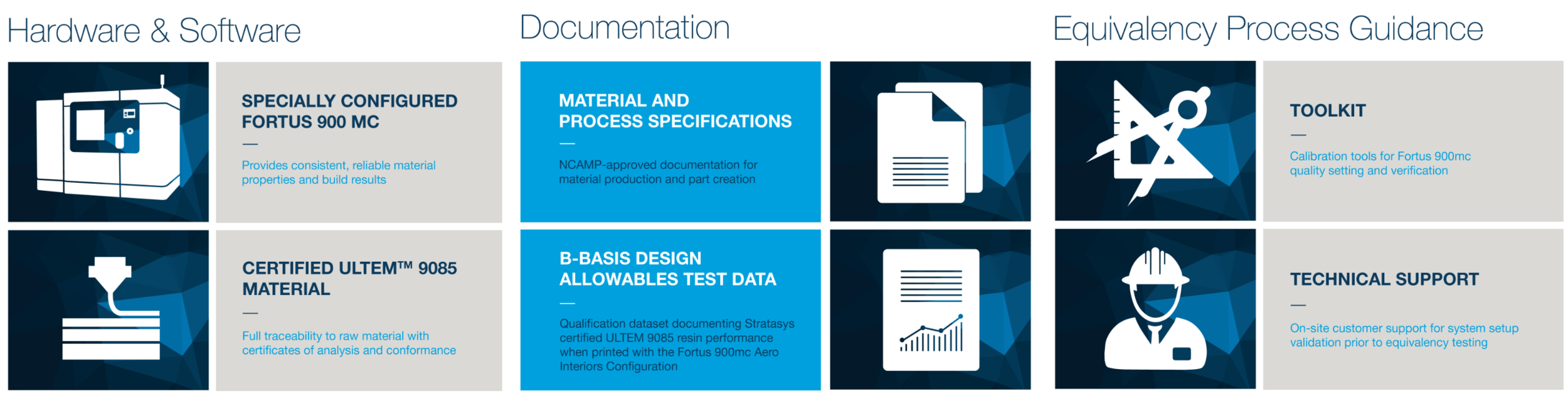

Stratasys announced what they call the “Fortus 900mc Aircraft Interiors Certification Solution”, which is a series of elements that can comprise this certification. It includes things like:

- FAA-compatible certification of the resin used to make ULTEM filament

- FAA-audited filament production process

- Fully certified traceability of material from “pellet to filament”

- Upgraded filament deposition process for more consistent mechanical properties

- Comprehensive NCAMP qualification test program, including statistical analysis and testing for high confidence

- On-Site Process Guidance to qualify system setup

These features should allow manufacturers to produce flight-ready aircraft interiors on suitably configured Fortus 900mc systems, whereas other 3D printers may not be permitted to do so. This is a huge step for Stratasys, deepening their venture into aerospace.

One can imagine further certification programs appearing for additional aspects of aerospace manufacturing by Stratasys.

I can only imagine the work Stratasys must have undertaken to get to this stage; it now sets a high bar for their competitors, who must take the same journey through the certification world to match Stratasys’ new capabilities.

Via BusinessWire