What should we make of the two surprise announcements by Formlabs?

The company announced two entirely new products to complement their current resin-based desktop 3D printers: the Fuse 1, a powder-based SLS 3D printer, and the Form Cell, a robotic system capable of turning a set of Form 2 desktop 3D printers into a powerful production factory.

What struck me about these two machines, which no doubt Formlabs has been working on behind the scenes for years, are for an entirely different market segment from their traditional targets.

The company started years ago by producing a desktop 3D printer, nominally suitable for hobbyists. It was quite successful, and led to the investment that took the company to its present state.

Their most recent product, the Form 2, was a more sophisticated version of the original product, so much so that it was possible to market it to professionals, such as dentists and designers wishing to produce prototypes. That was a bit of market switch, but far less than what seems to be going on now.

The new products offer very different capabilities that are best for completely new audiences. But who are these new products for?

The Fuse 1 seems to be targeted at industrial users who would otherwise use more expensive systems from 3D Systems and EOS. These users would be printing strong nylon prototypes or production parts with their equipment for a variety of applications, including medical, design and manufacturing.

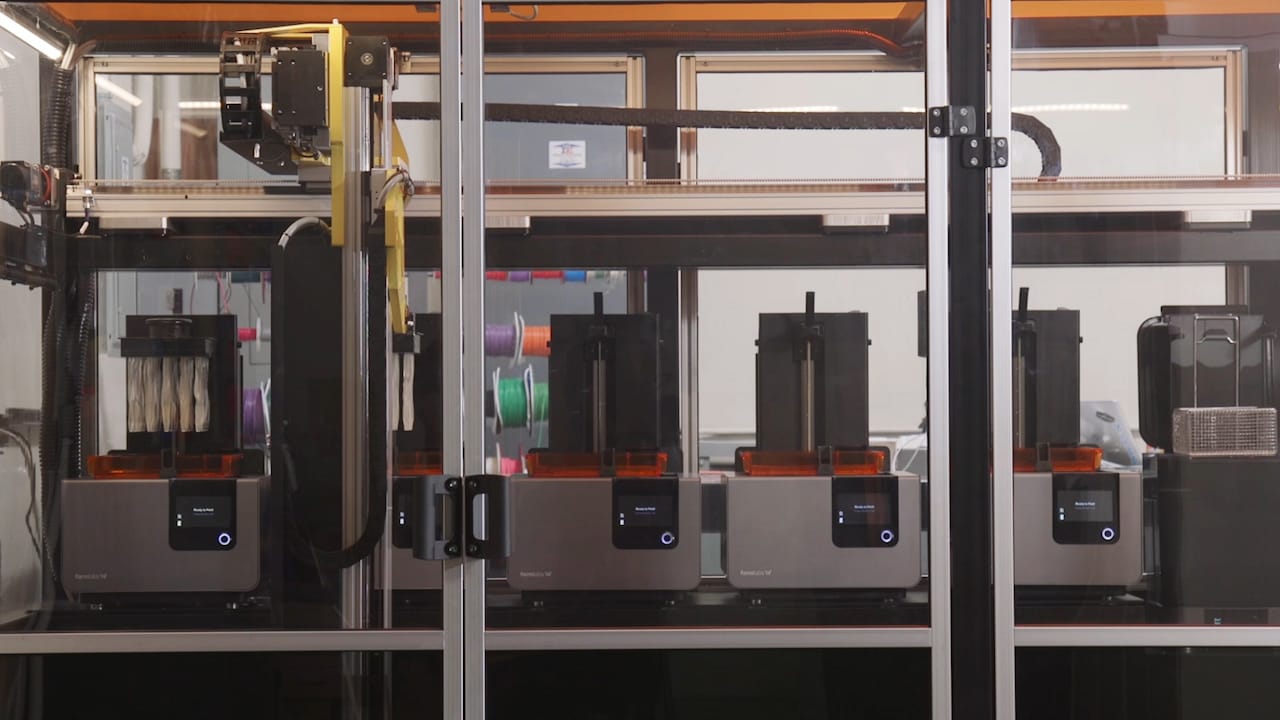

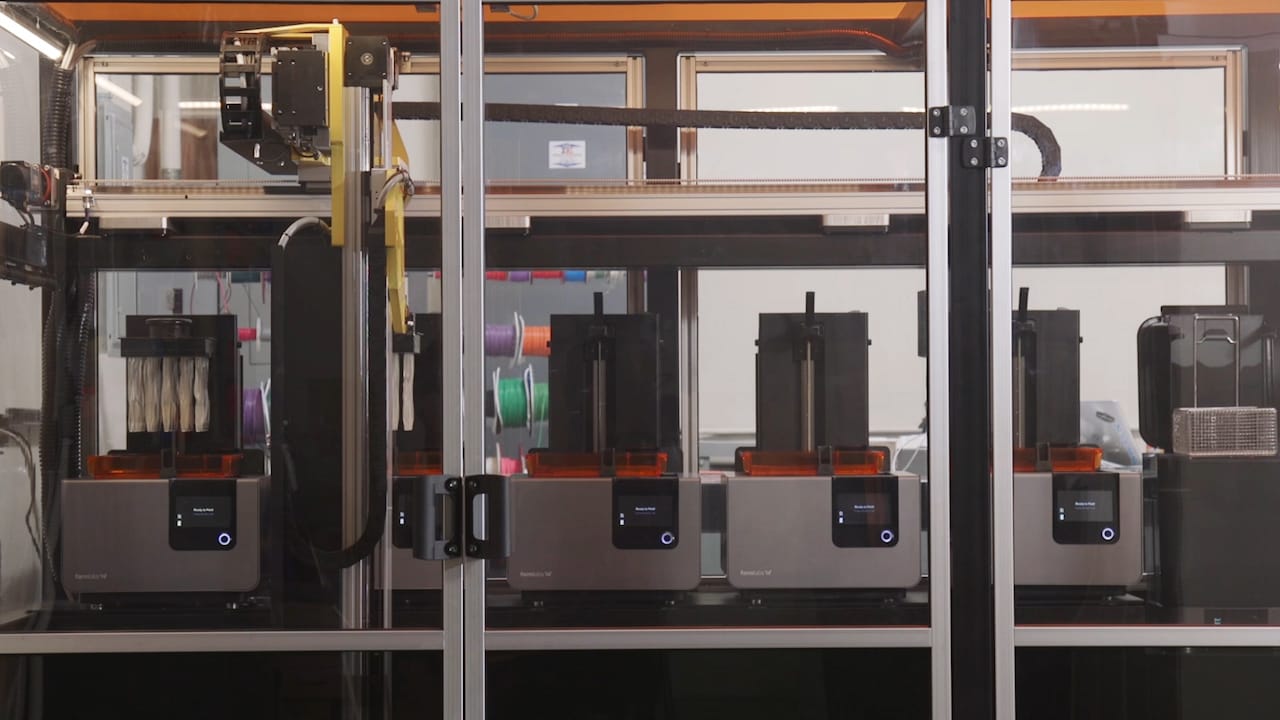

The Form Cell would be used to set up a kind of production line in which the machines would, if provided with a supply of resin, trays and 3D models, would print objects continuously, just like a factory. It’s really a kind of manufacturing system.

And that’s about as far as you can go from their original mandate of a consumer-style desktop 3D printer.

The Form Cell seems to have only two competitors: 3D Systems’ prototype Figure 4 SLA system, where a robotic arm can move completed prints through a series of finishing stations, in a manner very similar to what seems to be happening on the Form Cell.

The other competitor would be Stratasys’ newly announced Continuous Build Demonstrator, for which we recently got a very inside look. This concept, like the Form Cell, can continuously print 3D objects until supplies run out.

All three of these system are directed at manufacturing, in a way to persuade manufacturers that 3D printing isn’t a kind of standalone, manually operated machine that really doesn’t fit into their sophisticated production process. No, Stratasys, 3D Systems and now Formlabs all intend on deep integration into manufacturing automation.

Another strong implication of these announcements is that Formlabs now has a much larger – and potentially much more profitable – market to address. How many manufacturers might purchase a Form Cell? How many Form 2’s will be sold implicitly as a result of Form Cell sales? How many EOS and 3D Systems customers will choose to buy a less expensive Fuse 1?

In a way, Formlabs is following a pattern here: their Form 2 device severely dented the market for expensive commercial SLA units from other vendors. Now they are doing exactly the same thing for the nylon powder 3D printer market. At this rate, one might expect them to announce an inexpensive 3D metal printing next year sometime.

I think Formlabs has now officially transformed itself into an industrial 3D printer company.

Via Formlabs