We had the opportunity to sit down with the CEO of one of the most interesting 3D printing companies around today: Rize, Inc.

Frank Marangell is the CEO of Rize, who this year have released their fascinating and highly extendable 3D printing technology. Their process provides an ability to 3D print isotropic parts with literally no post-processing requirements.

UPDATE] We have learned that since our interview took place, Mr. Marangell is no longer President and CEO of Rize. However, his statements still provide significant insight into Rize’s operations and technology.

In the future, they hope to deliver full RGB color printing, as well as automated surface smoothing. It’s a very powerful technology.

Fabbaloo: The time required to do the post processing shrinks so much that they can do more printing in the same time?

Frank Marangell: They can do more printing. If this part takes 2 hours they can get it right up to the owner of the part. If they have to wait, it may take 2 hours to sit in a tank. First they have to make sure the tank is available, is it used by another party?

It’s not that the printing is kind of a parallel process; post processing is a very serial process: you do one at a time and it takes a lot of expertise. Often they’re not aligned: post-processing is idle and all of a sudden there’s a backlog and you might as well not run the printer because of the big backlog here in front of post processing.

Many people have said when they have intricate pieces on a part, it’s critical it gets out tomorrow they built two just in case in post-processing they ruin one!

They don’t have time to make another one, so when you have somebody with an Xacto knife or water jet blaster you have a high-risk that you don’t have the same part with the same quality on every part that goes out the door.

When I worked with Objet, I could not work that water jet. The guys who worked those machines were artists! They could clear the spokes on a wheel on some of the bicycles that we produced! I would break the handlebars and they could they could actually get the spokes to be defined. I don’t know how they did it.

If you can avoid all of that, you are better off in the process and that’s kind of the you know that some of our one of our benefits.

Fabbaloo: You’re heading towards CMYK color and smoothing but there’s so many other things you could deposit, like conductive material or flexible materials and much more. What’s next?

Frank Marangell: We will take them one at a time, unless there’s some big company, a government or somebody that said here’s a couple million dollars and we want you to change your priorities.

But let’s say you wanted some other color, like red. We could add do it, but I don’t plan to do it. You can’t use text on black. It doesn’t make sense, but OK you want black and you don’t care about text. Alright, I’ll do it for a minimum order. That’s easy.

But maybe you want to make, say, antennas. We are talking with some of the government guys, maybe they want to embed

some characteristics that you can’t tell from the outside but you can maybe get some signals if you know it’s there through some secret mechanism, you know, kind of an FBI thing.

We’re a startup company – we’re very flexible! The only thing we don’t have his money so we’re wide open to anything. We’ve got the IP, we got the flexibility. We need to do the color and the surface smoothing, but if you want to set up a separate project, we’ll build a team you know what helps us grow.

It’s the same with materials. We went out looking for money but if you are a big plastic company and you would like to have materials for our machine, let’s partner!

You have to match the solubility parameters of the inks in the new material. Let’s say a polypropylene (which is not the next one I’m working on), I will happily cut you in more than just the material cost on every kilograms that we sell. We’ll have a family of materials and we will have partners.

Fabbaloo: Right now you offer a polycarbonate-like material. One of the themes we keep sensing is that engineers say “I won’t buy that printer unless it prints the exact material I need”.

Frank Marangell: Great question! And I would add: with the exact mechanical properties in XY and Z, not just X & Y.

Fabbaloo: There is an emerging class of desktop 3D printers that can print exotic materials like PEEK or ULTEM. Do you fit into that world?

Frank Marangell: I fit in better than that and I’ll tell you why. Let’s pick the Roboze machine, for example. It has a reasonable price for USD$40-50,000 and is reasonable to print PEEK and ULTEM but they don’t have a heated environment. They probably do a pretty good job because they have a quite nice product but I would want to test the Z strength because I don’t know what the full mechanical properties are of the printed parts and they don’t have soluble support material for those materials; they only have it on ABS and PLA. I don’t know how you get supports out of anything that has any kind of complexity. ULTEM is a strong material so it makes it even harder to cut out the supports.

I have a MakerBot part that I use in comparison to show that with all the desktops, it doesn’t take much complexity to make them unusable for industrial parts. Yeah you can make some fancy stuff – I download from Thingiverse, but it’s not reasonable. Just a simple part that has a couple of little grooves, nooks and crannies and you can’t get the supports out and it’s unusable so I would say the same thing: did you go all the way or are you going to halfway?

We’re taking the long road. It’s our software, our extruder, our electronics and our firmware. We’re going to attack these things very professionally. We didn’t come into the market until we were ready to introduce it. We didn’t pre-announce anything. We did some beta testings at some serious customers and we’re now ready to sell machines.

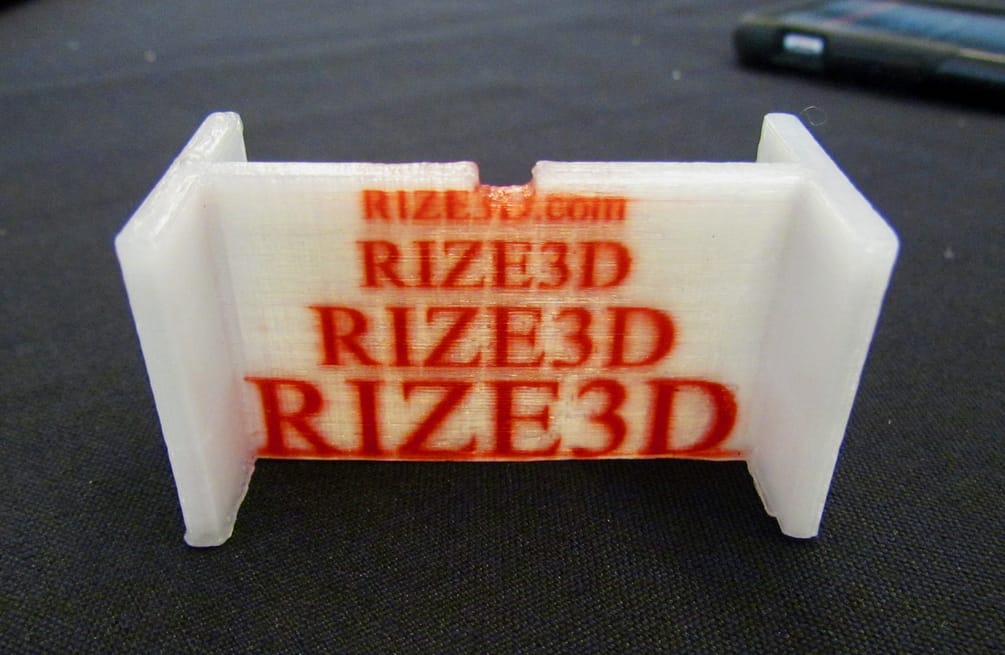

And we’re selling this version. We’re not selling the color version yet. We’re not overselling the futures. We’re selling this machine, and people love it because of what it can do for mechanical design, prototypes, manufacturing and tooling. We’re making an isotropic plastic part right now that has text and images on it in one color that has virtually zero post-processing

It’s not good for everything but it’s better than most of the things in this room here for rigid, real plastic. You can have the photopolymers – they’re amazing! I was an Objet guy, and I wish we could have the surface finish and feature detail that we had at Objet, but we could never leave the parts in the car when we went to lunch in the summer because they would be melted when we came back. They’re brittle and so they are great concept parts but they’re not real engineering plastic parts.

Fabbaloo: How’s your funding going?

Frank Marangell: We just closed a series A round in March, which is great. I think series A is the hardest to do, but it’s not my expertise as running companies and selling stuff is my expertise. Funding is not my expertise from the past, so this is all great experience.

We got seed funded two and a half years ago; we just closed our series A round in March and that will take us to the end of the year, maybe a little longer where we can prove many more installations: a hundred+ installations, where any of the risk that people might have had about market acceptance in this very crowded market space will have been relieved.

That’s the problem. We had 4 customers, and a product I thought was proven – but we only have 4 customers. One of them was in an office environment, in a cubicle, 40 engineers all sharing some of the printer. It’s a great story. But it’s just one installation.

If somebody comes in and buys 32 units to put across their offices, then the VC’s – and I don’t want to downplay VC’s, they’re finance people and often they’re not technologists, so we need to prove that we can carve our place in the marketplace to get around early next year, let’s say. That should take us to profitability.

Right now we need you to help us get the word out in this very crowded space. I do feel sorry for those bankers that are trying to figure out whether this is viable or not. When they try to determine what’s the difference between them or them or them I tell them everybody that is an FDM clone has no IP is just another industrial design in an expired patent product, that they’re not going to exist, they don’t make material, that they probably not even make their extruder or their software or their driver boards. Any mechanical engineer can can come out with those machines.

We are different. We are very unique and have some clear value propositions that is not matched anywhere else. It’s good we got that behind us for the short term for the next nine months or so.

I was able to convince a pretty good channel in the US over the last 3 months. Only since February have I been building channels and now I have all 10 territories covered and some of them have two or three dealers in each territory. I think the results of that it will start to pay dividends.

We will start making the transition from direct sales to channel sales. We’re all going to start transitioning to supporting the dealers so my sales guy is going to be channel sales manager instead of a direct sales manager, for example.

This is part 1 of a 2 part interview. Part 1 is here.