Another 3D printer manufacturer has developed a professional-level version of their desktop 3D printer.

Sweden-based Magicfirm Europe AB has been producing unusual desktop 3D printers under the brand name ZYYX since 2013, when they introduced their initial machine. This unit offered some interesting features, including automated bed leveling, a rarity at the time, as well as several easy-to-operate features. What was of most interest to us at the time was their “fume free” system, in which airborne emissions generated by hot plastic were captured in a filter system, unique at the time – and still not frequently seen.

Then in 2016 they introduced the ZYYX+, which included a number of upgrades focused on increasing build quality, such as an all-metal frame.

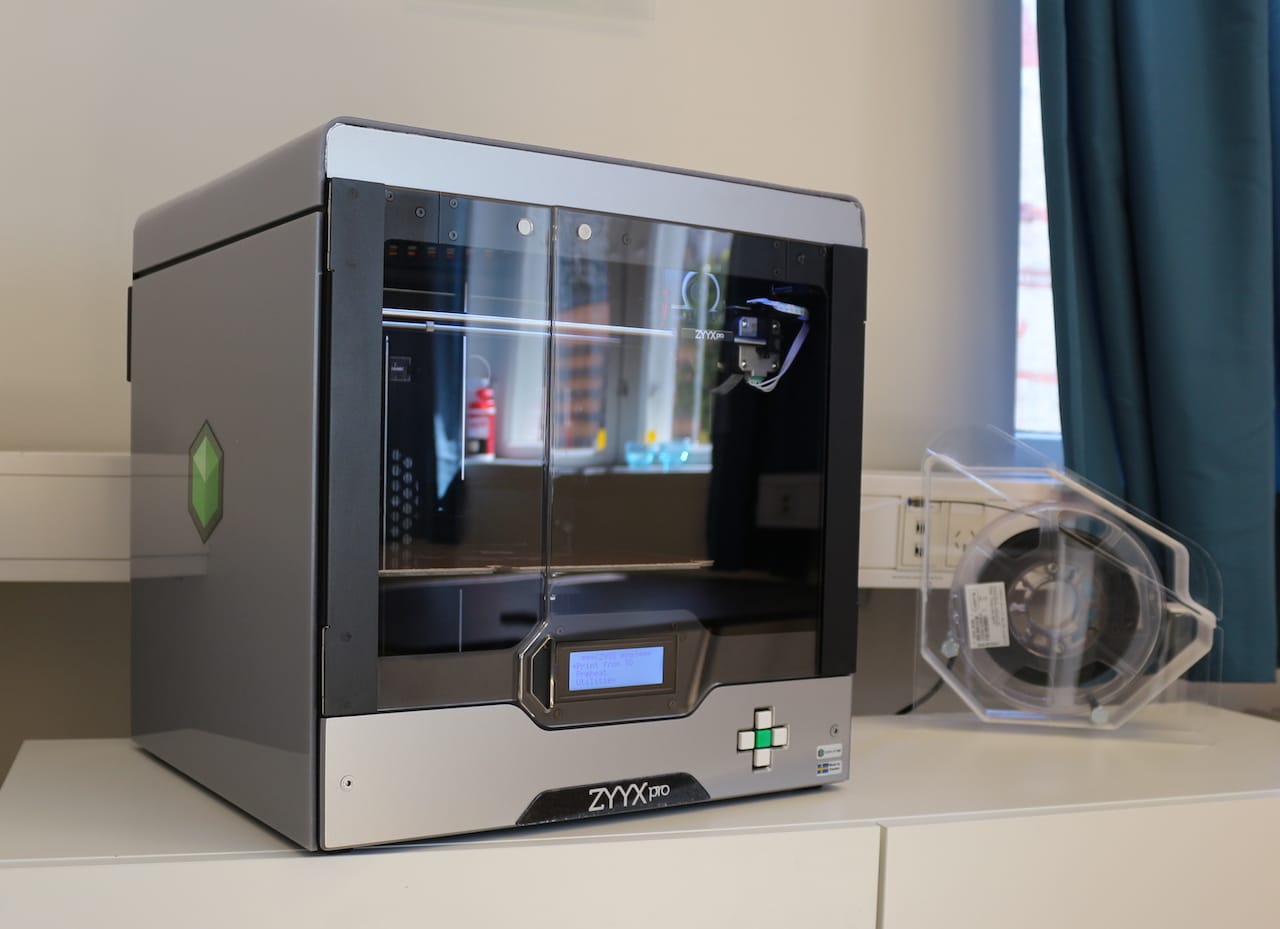

This year they’ve released the ZYYX pro, which takes an entirely different approach to their market.

The ZYYX pro inherits all the great features of previous models, but now includes the ability to 3D print exotic engineering materials.

Parallel to the announcement of the ZYYX pro, Magicfirm Europe also announced three such engineering materials: ZYYX proCarbon (carbon reinforced polyamide), ZYYX proNylon (plain polyamide) and ZYYX proKev (Para-aramid fiber reinforced polyamide).

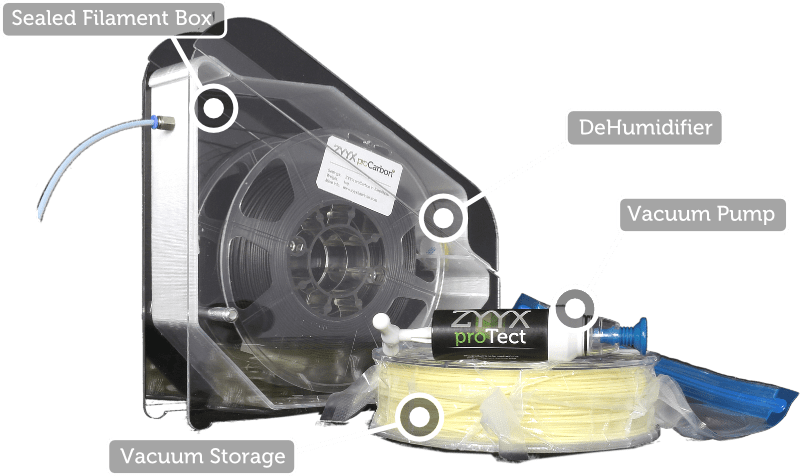

But there is a lot more than just a machine that runs hot enough to 3D print these materials. It seems that the ZYYX approach involves a kind of “system” for handling materials. There are several elements to this.

The heated chamber and extrusion temperatures are capable of 3D printing such engineering materials reliably.

An extension kit permits the use of PLA and ABS plastics in the same machine.

The same kit also includes a variety of nozzle sizes to enable fine 3D printing details, or rapid coarse prints as required.

An extruder swap-out system called “SwiftTool” lets you change the tool head in less than a minute, something very useful if you intend on printing in different materials frequently.

Their “proTect” Material system, shown above, is what they call an “ecosystem” for handling filament. The idea here is to maintain the highest quality conditions for storing and using plastic filament, which can be compromised by exposure to dust and humidity. It involves a sealed filament box during printing and a way to vacuum seal stored filament.

This last feature is something not present on virtually any other machine; it is often left to the operator to figure out ways to maintain filament quality.

All this, combined with the office-friendly nature of the ZYYX system, suggests that the machine could be a very good fit for a professional office environment, where designers and engineers can quickly 3D print prototypes in a variety of strong materials.

This machine should join this short list of professional machines we’ve been seeing grown in recent months.

The ZYYX pro is available now at a cost near €4,250 (USD$4,770), and the PLA/ABS kit is another €295 (USD$330).

Via ZYYX 3D Printer