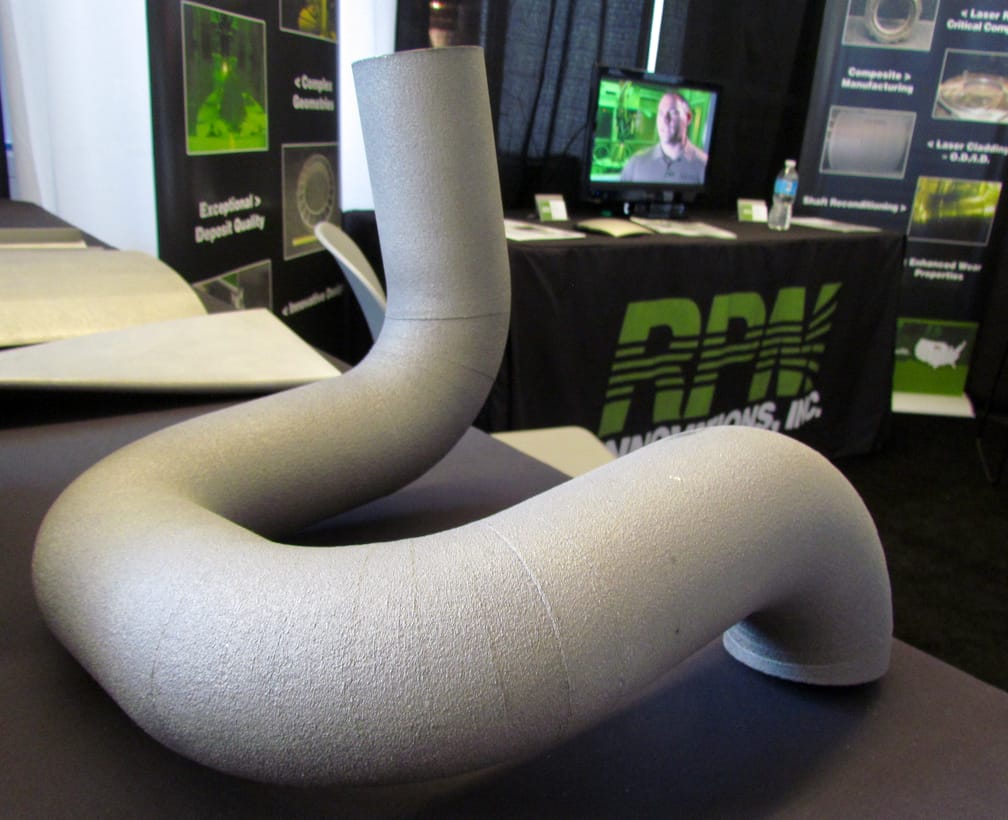

Most 3D metal printers offer relatively small build volumes, but not those from RPM Innovations.

RPM Innovations is a Rapid City, SD-based company that specializes in laser deposition technology. This technology can be used for a variety of purposes, such as metal cladding or metal repair – but it can also be used for 3D printing.

In fact, since 2009 the company has produced a large-scale 3D printer that uses this technology.

The printing process involves a fine metal powder that’s precisely blown toward the deposition point. Simultaneously a powerful laser intercepts the powder and swiftly creates a melt pool of liquid metal. By moving the deposition point, the system can 3D print solid metal objects.

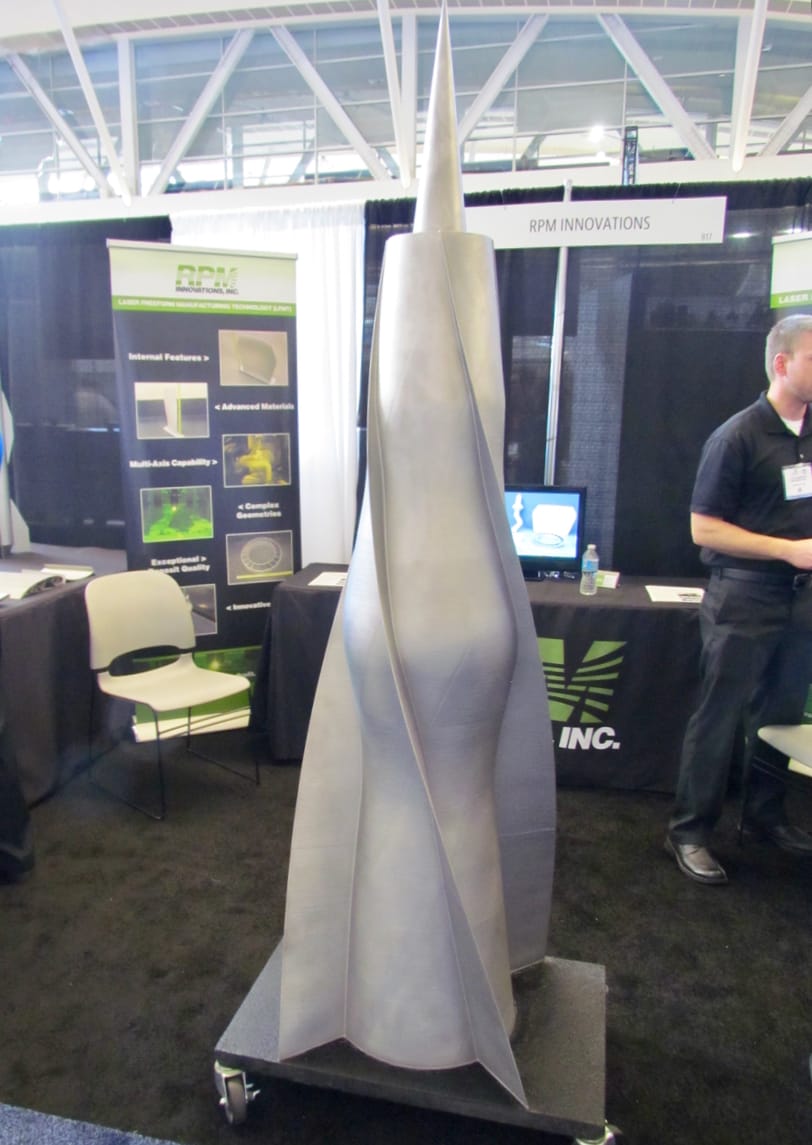

The nature of the process is scalable, even though it can handle thin walls as small as 1.5mm. RPM Innovations has produced a 3D metal printer whose build volume is an astonishing 1524 x 1524 x 2134mm.

How big is this? It’s sufficient to 3D print this gigantic nozzle / turbine / supersonic whats-it. Note that it’s positioned on a trolley with wheels as it is quite heavy.

They’ve been using this machine in-house since 2009, but began selling them to the public in 2014. The cost? It depends, but could be up to several USD$M’s depending on the machine size – that’s right, RPM Innovations can adjust the size of the machine to customer requirements to some degree.

Who uses this machine? According to RPM Innovations, they have clients in the aerospace industry (not surprising given the large print example above), the defense industry and the oil and gas industry, who must require all manner of large metal parts for their processing equipment.

For readers requiring gigantic 3D printed metal objects, there seems to be only one place to go.

Via RPM Innovations