The forgotten part of 3D printing: post processing. It’s a lot more complex than you can imagine.

There is so much focus on the “printing” part of 3D printing and what is often forgotten is the sometimes huge effort required to post process prints. From removing the print from the machine, to separating support structures to smoothing the surface, finishing a print can be a spectacular amount of manual labor.

Fortunately, there are companies willing to automate some of this process. One aptly-named company is Buffalo-based PostProcess, who produce a line of sophisticated machines designed specifically for post processing 3D prints.

The company offers products that address three specific post process issues:

- Support structure removal

- Surface finish refinement

- Waste water disposal

They offer a variety of machines for different materials and part sizes, for several types of 3D printing processes, and combinations thereof.

At top you can see their largest machine, the “BASE All Process”, which offers the ability to automatically remove support structures on parts printed with any of these popular 3D print processes: FDM, SLS, SLA and PolyJet.

How does it work? It provides 360-degree spraying and agitation, combined with detergents and controlled by sophisticated software algorithms that should, in their words:

Deliver uniform, high-quality results for every part, regardless of geometry, with short cycle times to meet high-volume production needs.

It is large indeed, as it has an internal maximum part volume of 1346 x 762 x 813mm, large enough for parts from the Fortus 900mc and from other large 3D printers. That or quite a few smaller printed parts.

You might get the notion that this is designed for large-scale 3D print production, and you’d be correct. In fact, the BASE All Process unit is set up for assembly line robotic handling, as the back door of the chamber can be opened for access.

Another interesting machine in the PostProcess family is the DECI Duo, which is again capable of handling parts 3D printed with various processes. It employs a powerful combination of circulatory and vibratory approaches. But this unit performs Support Removal, Rinsing AND Drying, all in one unit.

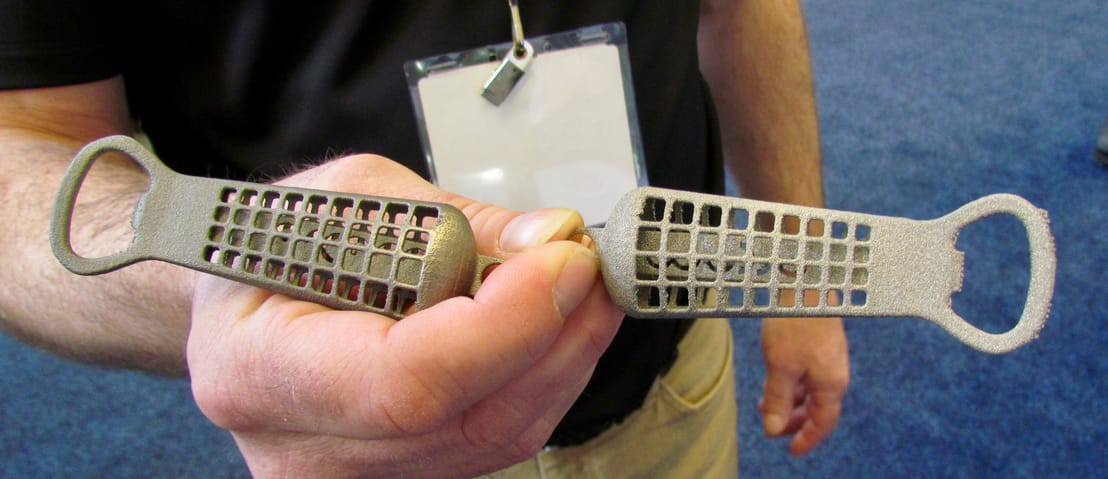

Their technology is not limited to plastic either. Consider this example of a raw 3D printed metal part on the right, and the same part having undergone treatment by PostProcess. It’s certainly not a perfectly smooth finish, but this was apparently obtained in only a few short minutes of exposure to their water sandblasting technology.

This could dramatically speed up metal post processing, as the partly-smoothed part could then be handed off to traditional finishing equipment for final touches, saving a significant amount of time.

These finishing machines are not inexpensive, as the BASE All Process unit and the Deci Duo could cost in the USD$85-90K range. However, for companies 3D printing large quantities of parts, they could be a very important way to automate the otherwise laborious process of finishing parts.

Via PostProcess