An innovative idea for a simple household object may hold the key to far greater use of 3D printing.

And by “key”, I mean an actual key.

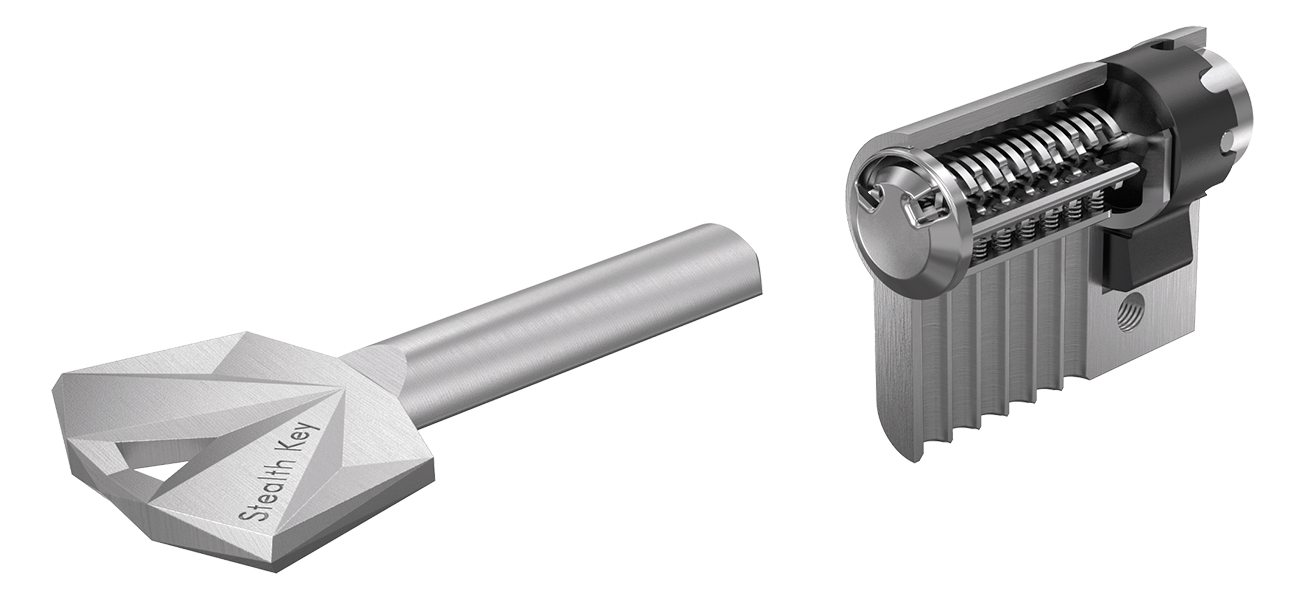

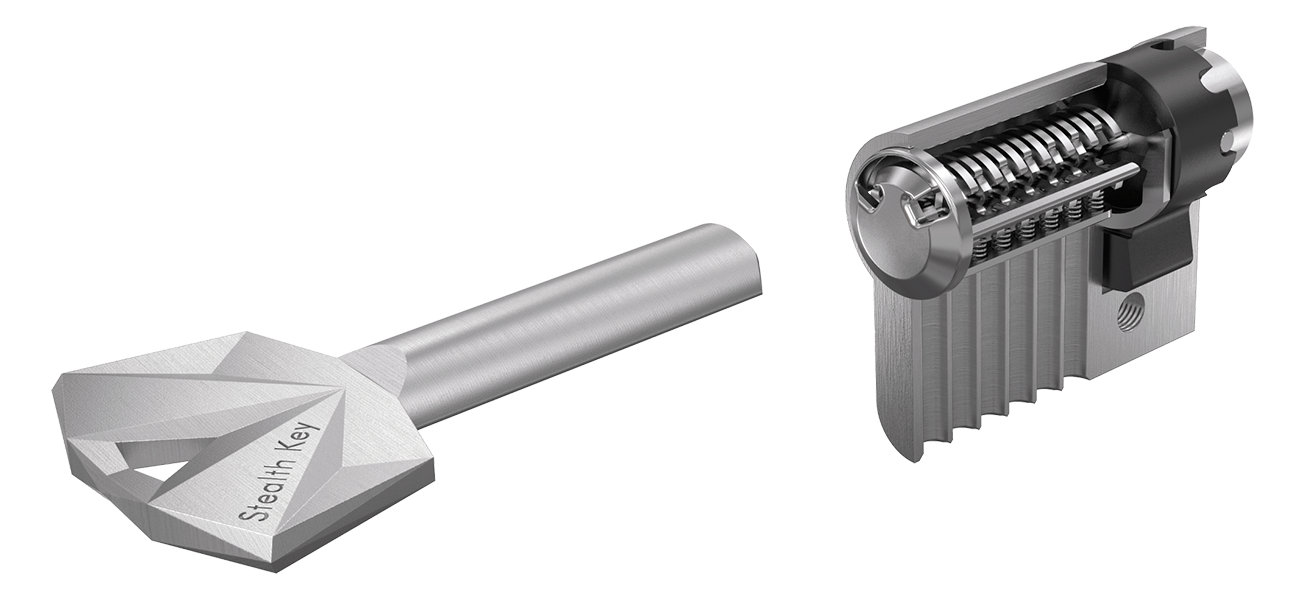

Swiss company UrbanAlps has developed a kind of “3D Key” for use in mechanical locks. It’s 3D printed in metal, titanium, actually, and provides far more security than commonly available keys.

The rationale behind this innovation is simply that existing keys are quite insecure. While you can keep them in your possession, it is surprisingly easy to defeat them through copying.

A standard flat key can be copied by making an impression in clay, photographing its shape or even tracing it on paper. Each of those provides a model from which a replacement key can be made. And sometimes that replacement key is made with a 3D printer, making the process quite straightforward for those with the right equipment.

Now UrbanAlps has developed a new key that has a 3D shape. From the exterior the “stealth key” appears to be a plain cylinder. That’s because the variable parts are on the inside of the key, away from prying eyes, cameras and clay.

The shape is sufficiently complex that it cannot easily be made with conventional making processes – an ideal target for a 3D printing application.

Of course, making the key itself is only part of the challenge. UrbanAlps also had to make the lock into which the key would fit. That’s quite challenging because today’s keys persist because they largely work and are considered reliable. The new key / lock mechanism would have to be just as reliable. A secure key is useless unless it actually opens the door!

The innovation is clear, but they may run into a few challenges in marketing this product, as it is likely to be far more expensive than a common key. Secondly, replacements for the keys will be equally expensive and cannot be quickly made at the neighborhood hardware store nor will local locksmiths be able to handle your request.

While this is certainly interesting, this points out a very interesting angle on transitioning to 3D printing.

A transition to 3D printing in an industry occurs when a new approach is devised that can only be addressed by 3D printing. The current costs of 3D printing are so prohibitive that any application that can be done in traditional making processes are done that way because it’s less expensive.

This is why many industries have not yet switched to 3D printing: they want to build the same products they’ve always made, and see 3D printing as a more expensive way of doing what they’ve always done.

The trick is to somehow figure out a way to create a product that leverages 3D printing in new ways, and that’s hard. It takes great creativity and imagination – like the UrbanAlps folks did.

But here’s the point: a traditional key is in fact a 2D item.

UrbanAlps transformed it into a 3D item.

And now the question of the day is: what items are in 2D form that could be in 3D form? Look around and you will see plenty.

That is one of many ways one can tackle the 3D transition.

Via UrbanAlps