At Rapid last week we spoke with representatives from German RepRap and found out something interesting.

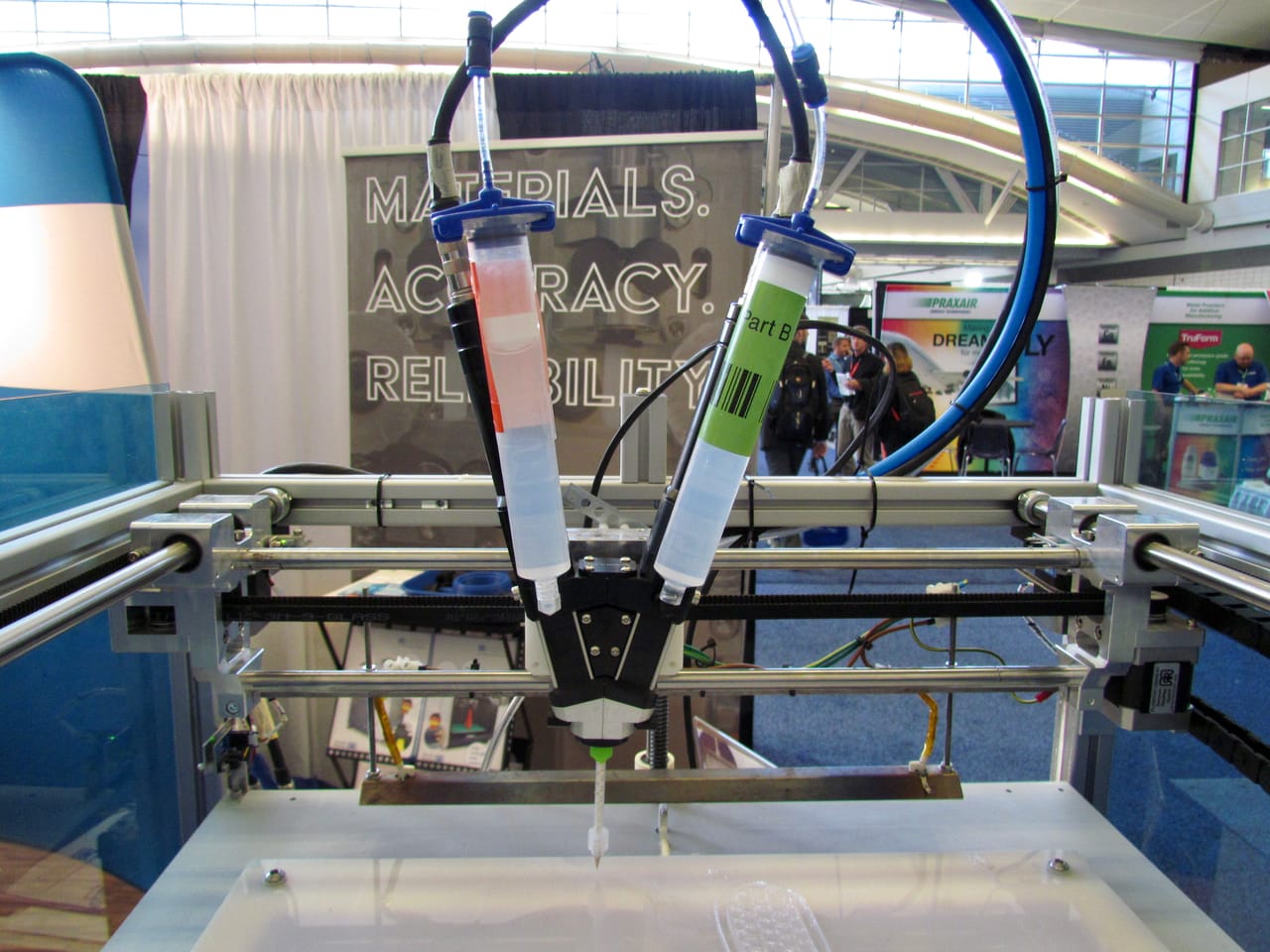

The company has been developing a 3D silicone printer using a new process they call “LAM”, or “Liquid Additive Manufacturing”.

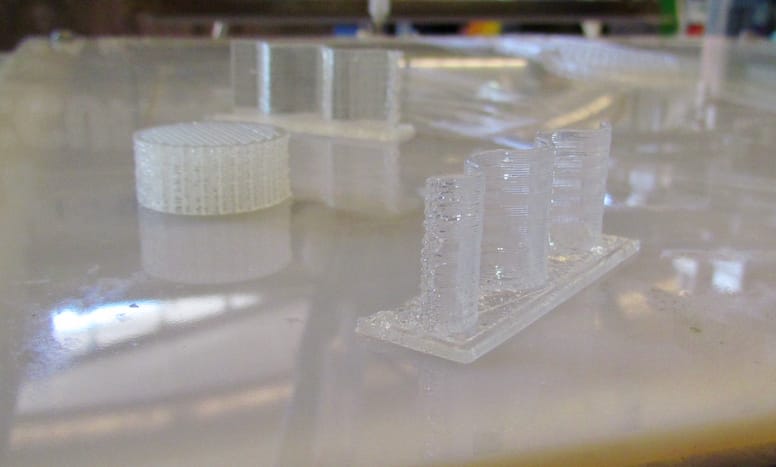

In the LAM process, two fluids are mixed at print time and, through precision heating, chemically react and become solid silicone. By moving the extruder around during this process, they can print very finely detailed silicone objects.

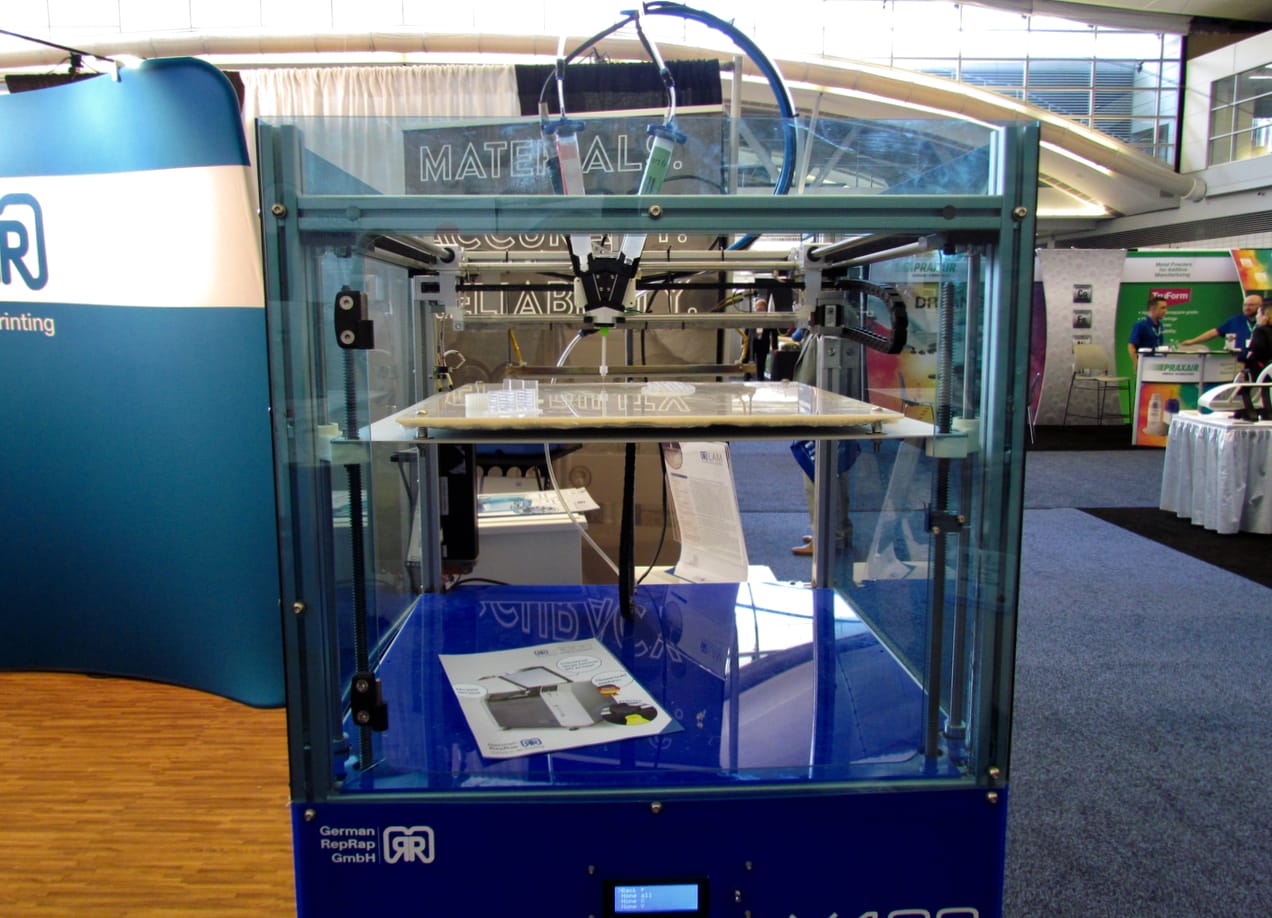

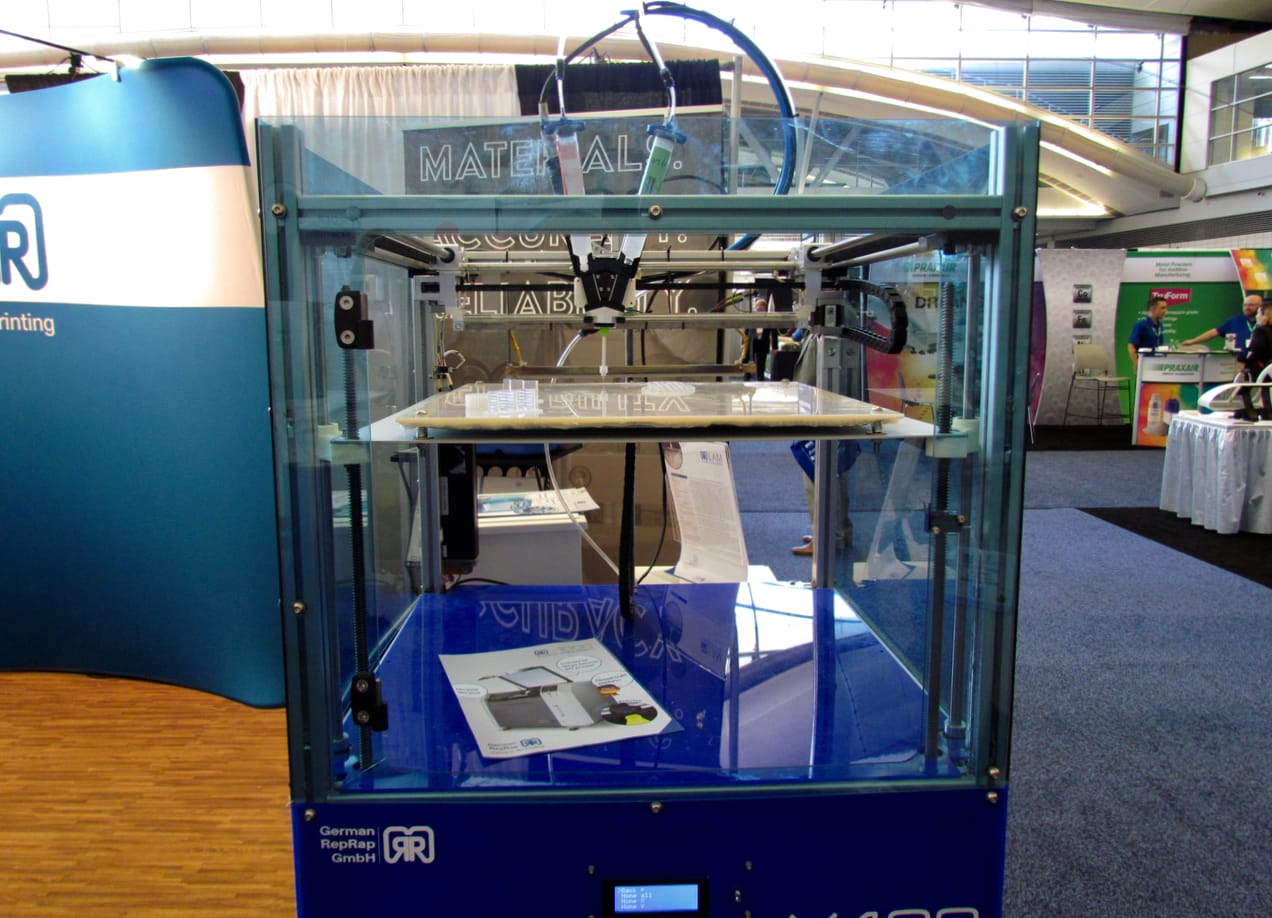

I first saw this technology at Solidworks World, where German RepRap was showing off a “demonstrator” of the technology.

Essentially, they had taken one of their popular X400 plastic 3D printers and modified it to use the new LAM extrusion system.

The results were quite impressive, although they were produced on a demonstrator machine that clearly wasn’t something you’d want to be selling directly.

But after our story and others detailing the demonstrator came out in the public, German RepRap were besieged with potential customers interested in the product.

As a result, the company has decided to actually sell the demonstrator! You can now order one for USD$65,000, while the true production machine using LAM technology won’t be available to the public until 2017Q4.

It seems there is very great interest in silicone 3D printing, as it would enable the production of highly unusual gaskets and flexible elements for new designs. So much so that buyers would ignore the niceties of a “normal” machine and be satisfied with the demonstrator alone.

This could be because there might be a significant advantage to having silicone 3D printing capability sooner rather than later. Imagine if you were able to approach your clients and show them incredible silicone 3D prints before anyone else did?

I think you might gather up some additional business and new clients.

And that’s exactly what German RepRap is doing.

Via German RepRap