Competition has lit up the progress of technology in 3D printing, and soon most vendors will have to include more features to keep up.

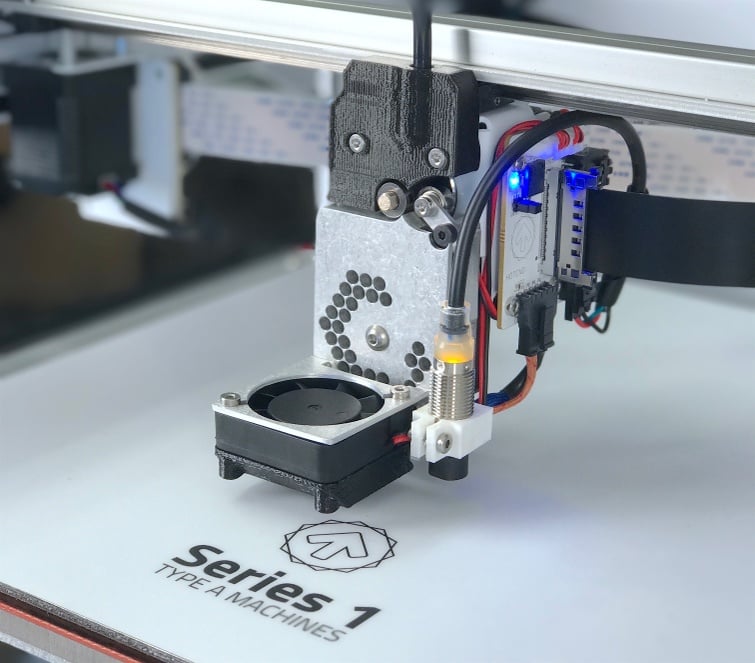

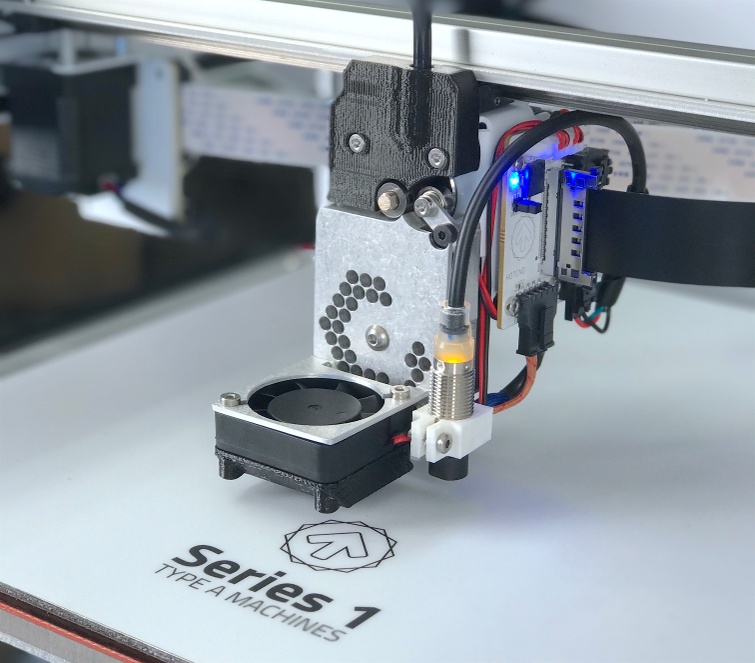

I’m reading a press release from Type A Machines, makers of competent professional 3D printers designed for prototyping. They announced several new features to their popular Series 1 line:

A flexible and removable build plate, fitted with a BuildTak surface for easier adhesion during printing – and easier print removal when finished. Flexible build plates dramatically reduce the fuss of removing sticky prints; just flex the plate and the print usually just pops off. No need for wrestling with scrapers and the potential damage to your fingers anymore.

An “adaptive auto-leveling” feature, in which they use a new sensor to intelligently handle leveling and calibration. They explain:

Adaptive Auto-Leveling, a hardware/software feature, uses a high-quality induction sensor to calibrate and correct for any build surface misalignment during print time. Unlike other active self-leveling methods, which inherently compromise the geometry of the resulting print, Type A Machines’ Adaptive Auto-Leveling relies on real-time error correction to ensure prints are square and true to the build surface, leaving your print geometrically uncompromised, while making 3D printing significantly easier and more reliable.

These are both excellent features to have on any filament-based 3D printer, so kudos to Type A Machines for including them.

Not a few years ago, a feature such as a removable and flexible build plate was considered unusual and was found only by adding components to your machine through third parties.

But once you did add one, it revolutionized your use of the equipment by significantly increasing printing reliability and ease of use.

Each time I’ve added features like this, I ask myself, “why don’t the printer manufacturers include this stuff in their standard products?”

It’s a good question because simple additions like these make the machines so much more usable, and that counteracts the main complaint about desktop 3D printers: they are hard to use and don’t work properly as often as they should.

But with Type A Machines’ announcement, we can see a pattern. How many new machine announcements include an auto-calibration feature? A great deal more than you’d have seen in previous years. How many have highly useable build plates? Same story.

I believe manufacturers are catching on and now increasingly including these and other reliability/usability features in their systems. There are enough 3D printer options now having them that it is possible you might say some of them are a defacto standard feature that buyers are now expecting to see.

This trend may hurt the countless 3D printer startups, most of which tend not to have “fancy” features included in their base machines. But as time passes, their thrift-featured offerings will be seen as less “basic” and more “deficient” in the minds of buyers.

And that starts to set a line in the desktop 3D printer market where you can’t successfully enter unless you are sufficiently funded to include at least the standard, expected features.

I think this is good news for buyers, as the equipment’s capabilities gradually grows. And we haven’t seen the last innovation by any means.

Via PRWeb and Type A Machines