I’m reading a story about a 3D printed surfboard, and it suggests another, wider use of 3D printing tech.

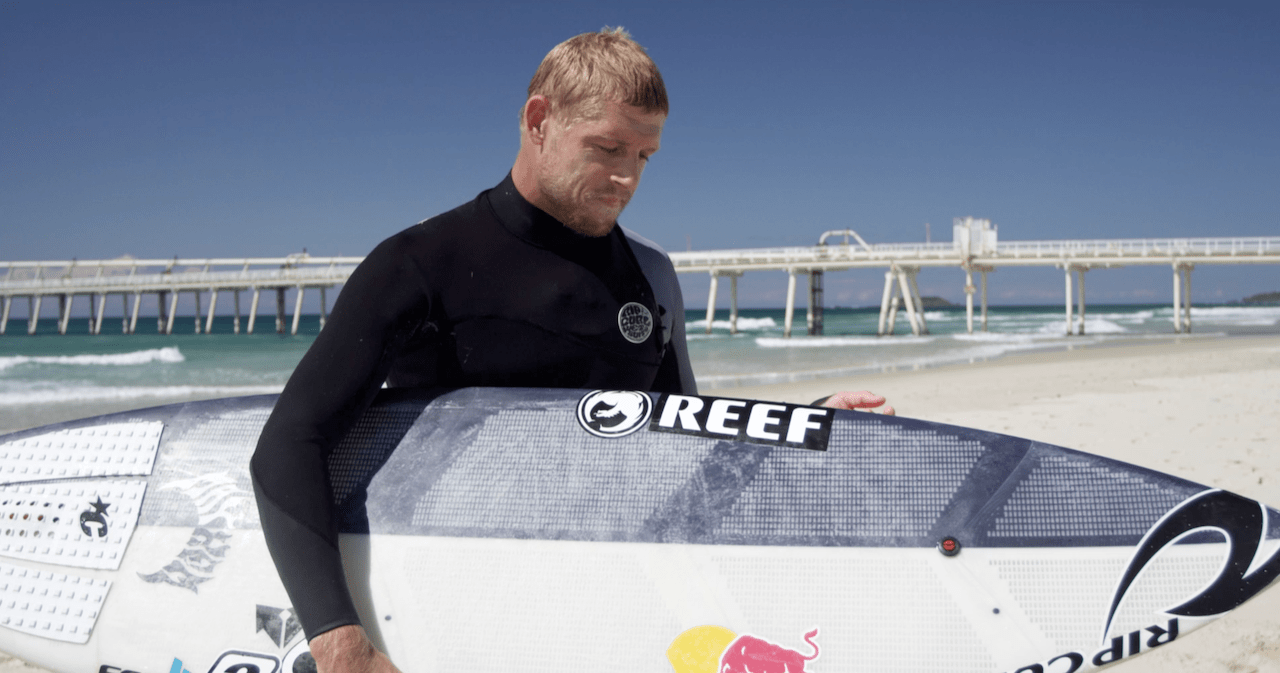

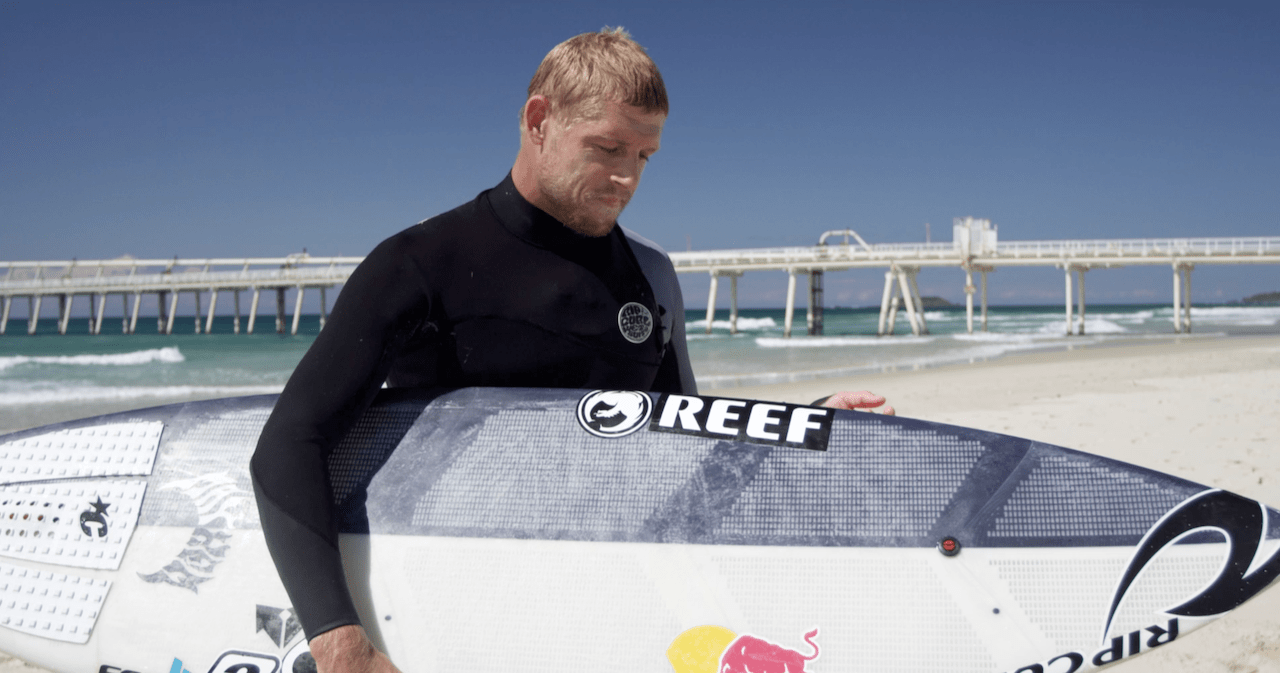

The surfboard in question was a kind of hybrid design involving both traditional and 3D printed elements, originally created by Australian professional surfer Mick Fanning in 2014. The “Trestles Mayhem” board was a highly advanced design, said to be equivalent to a “F1 treatment”.

However, since then a clone of the board design has been undertaken by Red Bull High Performance engineer Brandon Larson with prototyping and manufacturing service Proto3000.

The project involved 3D printing ten parts, taking over 100 hours of printing, then assembling them together into a board. Layers of fiberglass were then applied to form the exterior skin of the advanced board.

This sounds straightforward, but in fact the board’s design is actually quite complex, involving numerous subtle details, such as edge transitions, slight dips and “scallops”, whatever they might be. These details are obviously quite challenging to replicate using manual processes, but could be done using 3D printing to form the skeleton of the board.

The resulting board is quite strong, yet also light due to the sparse – and complex – 3D printed interior.

In the video, it seems the board works just fine.

But what’s interesting to me is that we have another industry that is taking on 3D printing and leveraging the technology as several other industries have done.

It may become normal for high performance surf board designs to now be produced through this process and marketed more widely than had been done previously. And as this process becomes more popular, the prices – and capabilities – of the products will fall and rise, respectively.

Now then, if the surf board industry can do this, what other sports-related industries could take similar advantage? F1 certainly has, but they are a bit more exclusive, as opposed to surf boards. There are a great many other sports that could do the same thing.

Via Red Bull