This month’s community support selection is Reflow, a project to assist third world countries through 3D printing.

Each month Fabbaloo selects a worthy non-profit project or activity contributing to 3D printing and provides not only a published story on the project, but also free advertising on our well-read pages. If your project would like to take part in the program, please fill out our application form here.

The project is centered around the idea of reclaimation of discarded plastic for recycled use as 3D printer filament. Currently they have operations in several locations in Africa and Asia.

There have been many attempts at recycled plastic filament, but most have had issues with print quality and some even seemed to be publicity stunts by companies trying to create some buzz over their commodity products. However, Reflow is different.

Here’s how they describe their work:

Reflow creates sustainable 3D printing materials with heart and precision. By building a vast international network for small-scale production, we transform local waste streams into premium material to match all your creative needs. By creating with Reflow, you support a vibrant community of makers, recyclers and waste collectors and help prevent the production of more harmful plastic pollution. Together we can ensure that the next industrial revolution is sustainable, global and inclusive.

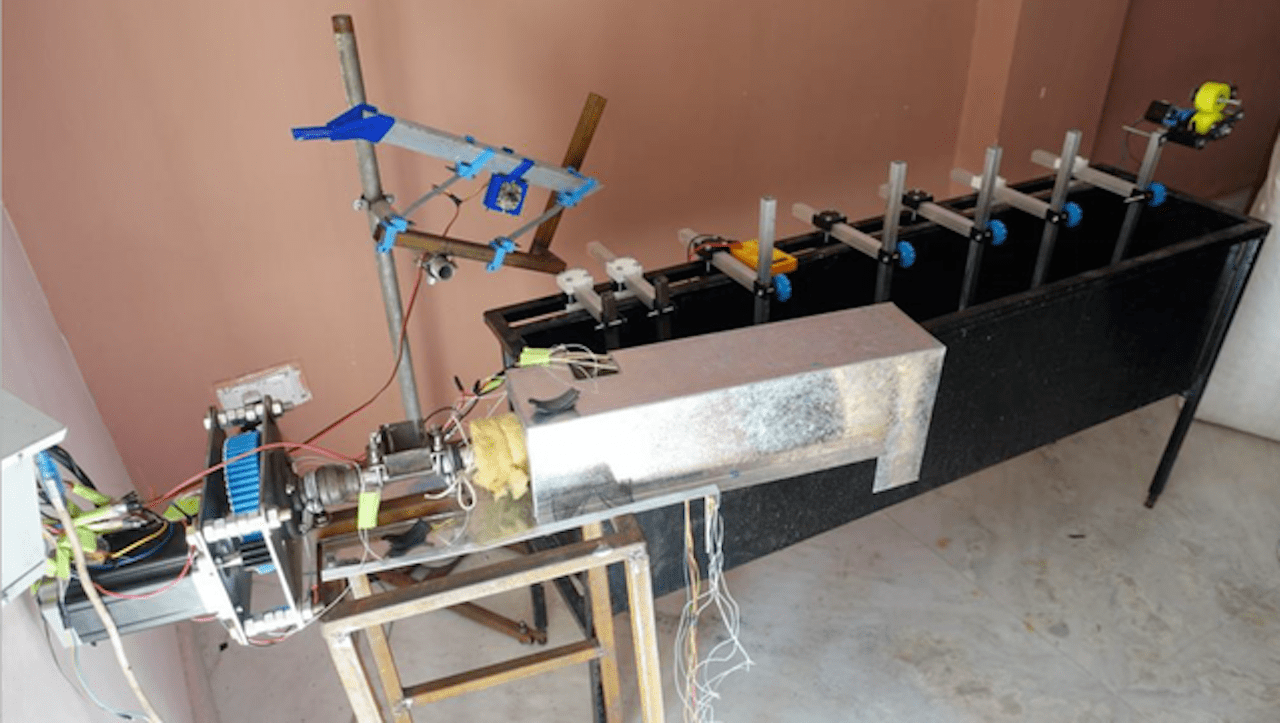

It’s most certainly a grand objective, but how is this done? Reflow has apparently solved the problem by developing plastic recycling equipment that actually seems to work, as we described in a previous story on the company.

The relatively inexpensive equipment can then be deployed in areas requiring assistance.

Any human-inhabited area produces many tonnes of waste each day, a phenomenon that has occurred since before civilization. Recently plastic has become a major component of waste sites, and as some of this plastic will essentially never degrade, it is important to find ways to recycle it.

One way is through 3D printing, by producing usable and practical 3D printer filament.

The method is to establish a collection service in a target location, where locals can sift through endless supplies of plastic waste to identify the right kind of plastic.

While the plastics found in a typical waste site will vary considerably, Reflow has found a way for workers to find empty bottles made from specific mixtures of PET.

These bottles are shredded into 6mm flakes that are ideal for use in recycling applications.

It’s then that the machinery takes over and converts the flakes into useable 3D printer filament.

I should mention that Reflow’s spools of PET filament are of good quality, as their equipment includes sensors to monitor filament quality, just as the other filament manufacturers do.

They also perform extensive testing with the filament with a number of partners to ensure it works correctly.

Finally, profits are reinvested in the originating community where the plastic was obtained, creating an economic lifecycle that appears to be sustainable.

Waste sites are truly gigantic, and they won’t go away with this initiative, but every bit counts.

And if you know of another nonprofit / open source project that should can take advantage of our community support program, please fill out our form.

Via Reflow