The Snapmaker is a very low cost desktop 3D printer that has now raised a great deal of money, but is this a good thing?

As I’ve written what seems to be countless times before, one must be quite suspicious of low-cost 3D printer startups. Numerous such ventures have failed miserably in the past and I’ve even written a checklist you can use to analyze the probability of success on such equipment.

The typical failure scenario that has occurred many times previously is a low cost – seemingly too low cost – machine, with some extra features, combined with a huge number of orders. If such projects are not planned – and executed – with great precision, large numbers of orders hugely amplify any planning errors, sometimes resulting in the failure of the project.

Some of these characteristics are present in the Snapmaker’s project: low cost and a ton of orders.

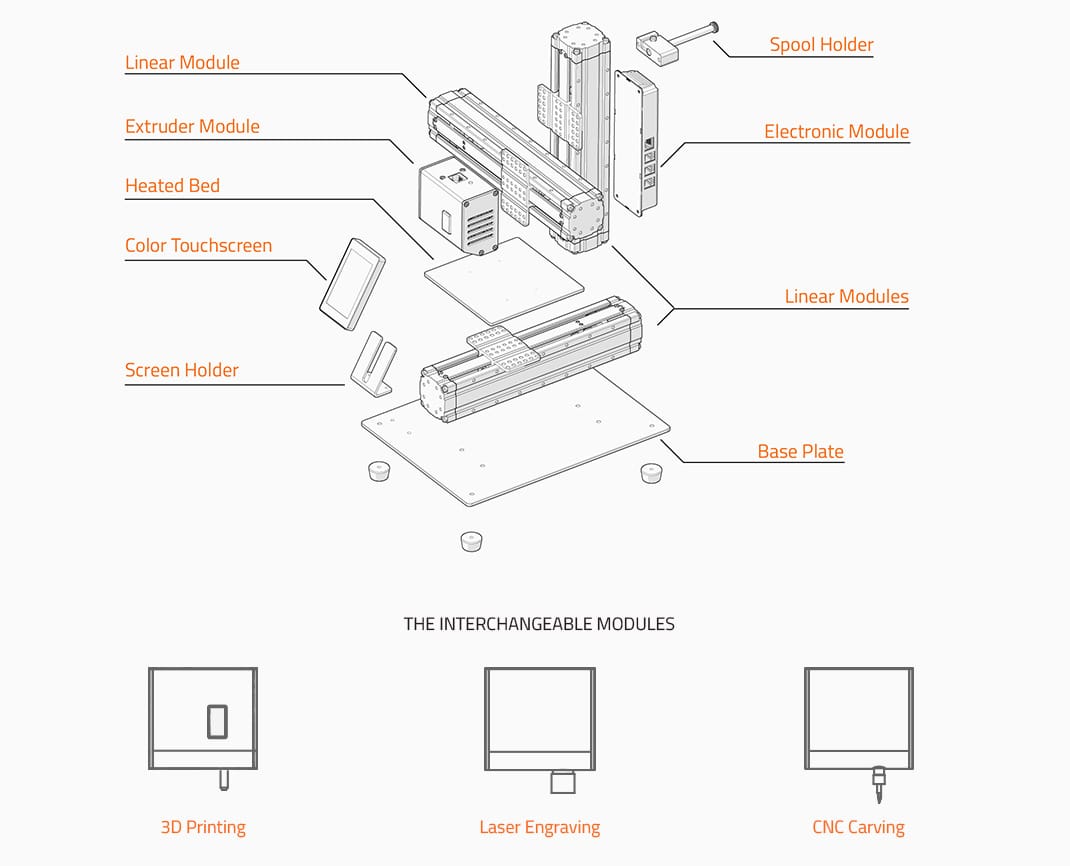

But what is the Snapmaker? It’s a desktop 3D printer that is made from all-metal modules that seem to snap together easily. The company says it can be assembled in only 10 minutes, which is pretty quick if you’ve ever had to build a 3D printer from scratch. It has a heated print bed, meaning it should be able to print some materials beyond basic 1.75mm PLA filament.

The metal design enables the avoidance of leveling procedures, as the rigid components likely hold the build plate in a known, completely level position.

The build plate is also coated with a semi-sticky material that should drastically reduce print errors, especially when combined with the heat.

One interesting feature is that the control board and panel are mounted in a moveable handheld unit that’s connected by cable to the machine. I’m not sure how useful this could be, but it might be unique among 3D printers.

But that’s not all. The machine also apparently includes additional modules to swap for the 3D print head, including a laser engraver and CNC mill. This makes the machine into a multi-function device.

I am a bit skeptical of multi-function machines like this, especially at low price points, where the additional modules are likely to be vastly underpowered for the functionality you’d expect. The minuscule 0.5W laser, for example, might be able to scorch some surfaces, but would take long times to do so. The CNC mill would have similar concerns. If these are truly underpowered, then operators would eventually give up on them.

And now the pricing: The pricing is extremely low, likely too low, at USD$299 for the basic 3D printer. Adding in all of the optional units raises the price to only USD$439. This extremely low price has attracted many interested buyers.

The leads to the other concern I have: whether this project can succeed, given the number of orders they’ve received. As of this writing, the project has been pledged over USD$1M for around 2,700 units. That’s a huge number of machines to produce for a small startup company.

You’d think a lot of orders could be a good thing, but sometimes it is not always the case if the company is not properly set up for mass manufacturing. Consider this: what if someone asked YOU to product 3,000 machines of good quality by September? Would you know what to do? It takes considerable manufacturing expertise to pull something like that off, and not every company has those skills and experience.

Does Snapmaker have these skills? Their campaign page lists only eight team members, which include: mechanical engineers, web developer, software developer, electronics, marketing and “operation”. I don’t see manufacturing expertise listed prominently.

I cannot say whether this project will succeed or fail, that is up to those managing the project. However, there are a few signs here that suggest this could be a risky investment.

Via Kickstarter and Snapmaker