An experimental 3D sugar printing process has been developed, but not for the reason you think it will be used.

In the past we’ve seen multiple attempts at food printers of various kinds, including chocolate, dough, peanut butter, ground meat and even Nutella. And there have been a couple of 3D sugar printers, most notably being 3D Systems’ ill-fated ChefJet. The ChefJet would selectively sinter fine sugar to create small, fragile colored sugar shapes. I actually ate one once, but it was not particularly notable taste-wise.

Since then such food experiments have continued, with small successes and a lot of failures. It just has not seemed to catch on for a variety of reasons.

But this project, by Pok Yin Victor Leung of MIT, has developed a 3D sugar printer that works. However, it’s purpose is most definitely not to print sugary treats for everyone.

No, it’s actually been developed as a kind of research vehicle. You may recall the 3D glass printer also developed at MIT from 2015? While this technology was proven to work, it also was very challenging to build, with extremely high temperatures required, and unusual glass materials. The temperatures were so hot components had to be made from custom developed ceramic parts.

The concept was too expensive to perform research on the highly desirable glass 3D printing capability, which would no doubt be gladly adopted by industry for an enormous variety of practical uses. However, the research would be limited because of the constrained access to the expensive equipment.

Leung devised a way to study glass 3D printing by producing a very inexpensive alternative that had similar properties: a molten sugar 3D printer. The idea was to adopt a common desktop unit to handle granulated sugar in much the same way that some machines use pellets instead of filament.

However, it turns out 3D printing sugar is a vastly more complex matter, as anyone who’s spent time in a kitchen will realize that heated sugar can carbonize, crystallize and cause other troubles.

Leung overcame this by adopting the long known practices of the candy industry:

Molten sugar (a mixture of table sugar and corn syrup used in candy making) has a similar material property to molten glass. They are both in solid state at room temperature and are

optically transparent. Their viscosities are both dependent on temperature.

A sucrose and fructose mixture exhibits a glass transition temperature from 57C to 69C and melts around 172C.

Dyes can be added to create different colors. Once cooled, the hardened sugar can be stored indefinitely in proper storage conditions.

Preparing the input molten sugar material is takes a few steps that would be familiar to candy makers:

In a typical batch preparation, 1000 g of table sugar is first wet with a small amount of water (*100 g). Five hundred grams of corn syrup (Karo Light Corn Syrup) is added to prevent sugar crystallization.3 This mixture is heated in a stainless steel pot over an induction heater at 1800 W until 100C and is continually heated at 1300 W until 154C. Water is boiled off from the mixture during heating, and the mixture’s temperature is an indicator of the remaining water content. One hundred fifty-four degree celsius is referred to as the hard crack stage in candy making and corresponds to *1% of water content.16 Stirring is not necessary as this may initiate crystallization. Sugar temperature is monitored by a digital thermometer (CDN DTC450 Digital Candy Thermometer). Food dye can optionally be added to the pot to provide color when the temperature reaches 145C. The molten sugar is poured into the printer reservoir and allowed to cool for 15 min until it reaches a steady temperature suitable for printing.

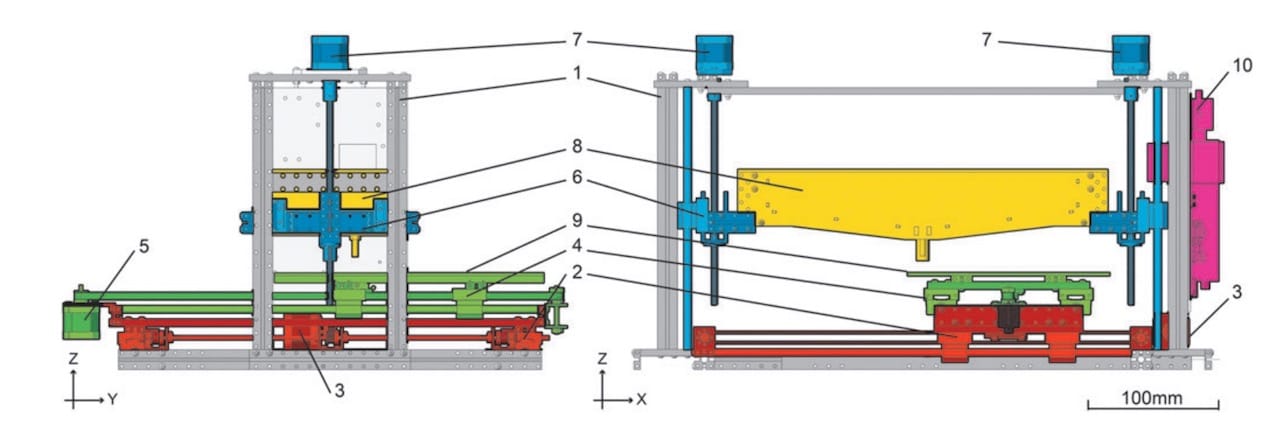

From there the material can be extruded from a suitably adapted desktop 3D printer. Essentially, they’ve built a large molten sugar reservoir that sits at the top of the machine, and it’s kept at a constant 98C to maintain the sugary molten state.

To commence printing they simply remove a plug and the sugar flows at a constant rate determined by gravity. The extruder moves in XY directions to effect printing.

It’s obviously a very rudimentary setup, but it accomplishes the purpose: develop a platform where molten material printing can be studied at very low cost. In fact, the cost of sugar used in this experiment was only USD$1.44 per kg. That’s a lot less than the cheapest material I know of for any kind of 3D printing.

The outcome I’m hoping for here is much research into molten material printing, where it could eventually result in the production of commercial 3D molten printers able to print in glass or other very high temperature materials.