I’m reading a paper by researchers from Northwestern University where they propose a new method of enabling 3D printed Lunar and Martian materials.

I’m not sure their proposal will be practical, but it is interesting nevertheless.

The problem they’re trying to solve is that of in-situ 3D printing in remote areas. Rather than shipping a building’s components from Earth to the Moon or Mars at (literally) astronomical expense, the notion is to use on site materials (soil and rocks) to produce the necessary structures.

There have been a number of proposals to solve this future dilemma, most notably from several NASA researchers.

But this new proposal comes from Northwestern University where researchers propose creating a “3D paint”. The Tissue Engineering and Additive Manufacturing (TEAM) Laboratory at that institution has long been working on 3D printing tissues, including simulated bone with great success. Now it seems they want to repurpose their tissue technology in deep space.

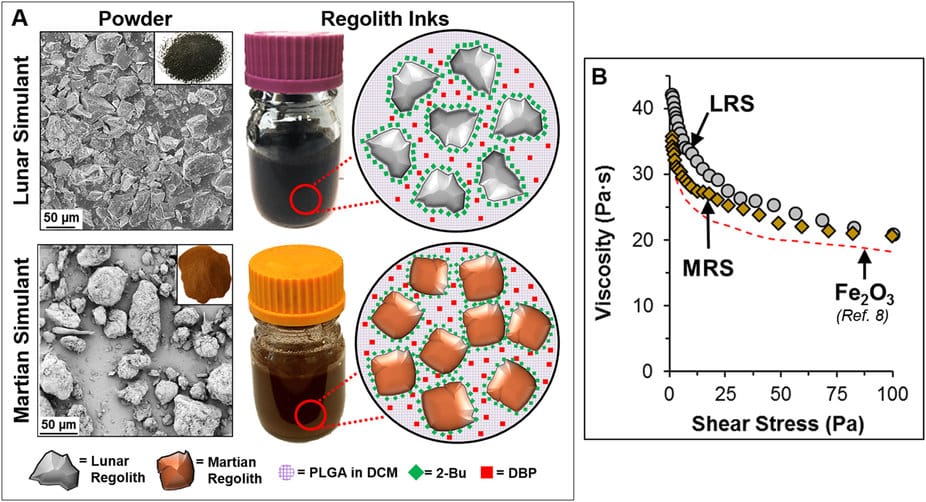

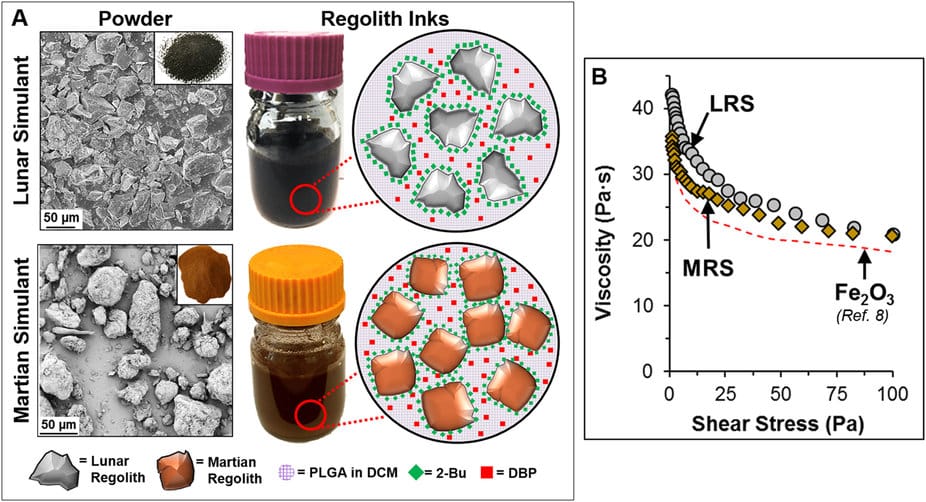

After reading their paper, it appears they are sifting Lunar and Martian soil simulants (yes, you can actually buy this stuff) to produce a powder with granules less than 1mm.

This powder is then mixed with a commonly found elastomeric binder, polylactide-co-glycolide. (Yes, you can buy this stuff, too). The resulting mix is an extrudable slurry that assumes a flexible shape. One can then bake the object to firm it up.

The research team has proven this approach works, but I have a number of questions.

I’m wondering how the polylactide-co-glycolide will work in the harsh environments intended for this method. On the lunar surface, for example, temperatures range from -173C at night to 100C during daytime. And it’s all done in a vacuum as well.

Unless the 3D printing process is taking place in an environmentally controlled environment, the polylactide-co-glycolide might freeze, boil or evaporate, depending on conditions. The slurry would have similar problems. But putting the entire process in a controlled environment would likely be quite costly.

The second problem I have with this approach is that the polylactide-co-glycolide apparently takes up 25-30% of the final material. In other words, if you want to make a 1 tonne structure, you must ship 250-300kg of polylactide-co-glycolide from Earth, as I don’t think you can find any chemical outlets in Mare Imbrium!

This would be fantastically expensive. How much? Astrobotic, quotes USD$1.2M per Kg to the Lunar surface, for example. So, in our 1 tonne building example, we would have to spend USD$360M to get the polylactide-co-glycolide to the building site. Oh, and send an environmentally controlled chamber for it to be used in as well.

As for use on Mars, well, it would cost somewhat more.

While this method technically works, I don’t think it would ever be financially feasible to use it. I suspect the best approaches for extraterrestrial 3D printing are methods that use only local materials and energy, like a laser sintering process, for example.

Via Northwestern and Nature