Desktop Metal has finally shown their 3D metal printing technology, and from a first look, it does appear to be game changing in several respects.

The mysterious east coast startup has been a bit of a puzzle for some time now. We’ve seen only glimpses of their equipment and hints of powerful capabilities. But now we know a great deal more.

While they announced two different 3D printer models, these machines actually use very different 3D printing processes. One uses a powder technique, while the other uses an extrusion system. Both, however, must make use of a furnace to finalize the part once printed.

One system is designed for office use, the Desktop Metal Studio, which is likely the first commercially available 3D metal printing system that you can use in typical environments. I’m quite surprised at the level of features included in this machine that enable it to be safely used.

The Studio employs an extrusion system to 3D print “specially formulated bound metal rods” containing a mix of metal and binder. Objects are 3D printed in the classic manner to create a “green part”.

The green parts are then placed in an office-friendly furnace that’s capable of up to 1400C. This post processing not only causes the binder to evaporate, but also to fuse the metal particles together to form a complete and solid metal object.

What’s fascinating about this machine is that the support structures are designed to be removed by hand and don’t require the installation of very expensive metal processing machines.

The price of a complete Desktop Metal Studio system, including all required elements is apparently only USD$120,000. That’s vastly less than traditional metal 3D printing equipment. They also offer an interesting “hardware as a service” pricing model for those unable to lay out the full charge.

Meanwhile, Desktop Metal also announced a Production system set to be delivered in 2018. This equipment does not use an extrusion system as the Studio system, but instead uses a binder jetting approach.

The Production system achieves high speed printing by using a “single pass” where powder, binder and support materials are distributed in each printer movement. This alone doubles the speed of printing. The binder jets are, of course, high resolution, leading to detailed metal prints. How detailed? Desktop Metal says the voxels are around 0.05mm on a side, comparable to the best plastic extrusion machines.

The Production system is designed for use in a production line, with appropriate controls and features, quite unlike its Studio cousin. I’m not even sure these two machines are cousins, they are so different from each other.

The parts printed on the Production system are easily post-processed, as the single pass motion also drops binder-inhibiting material to ensure supports easily break off by hand after printing.

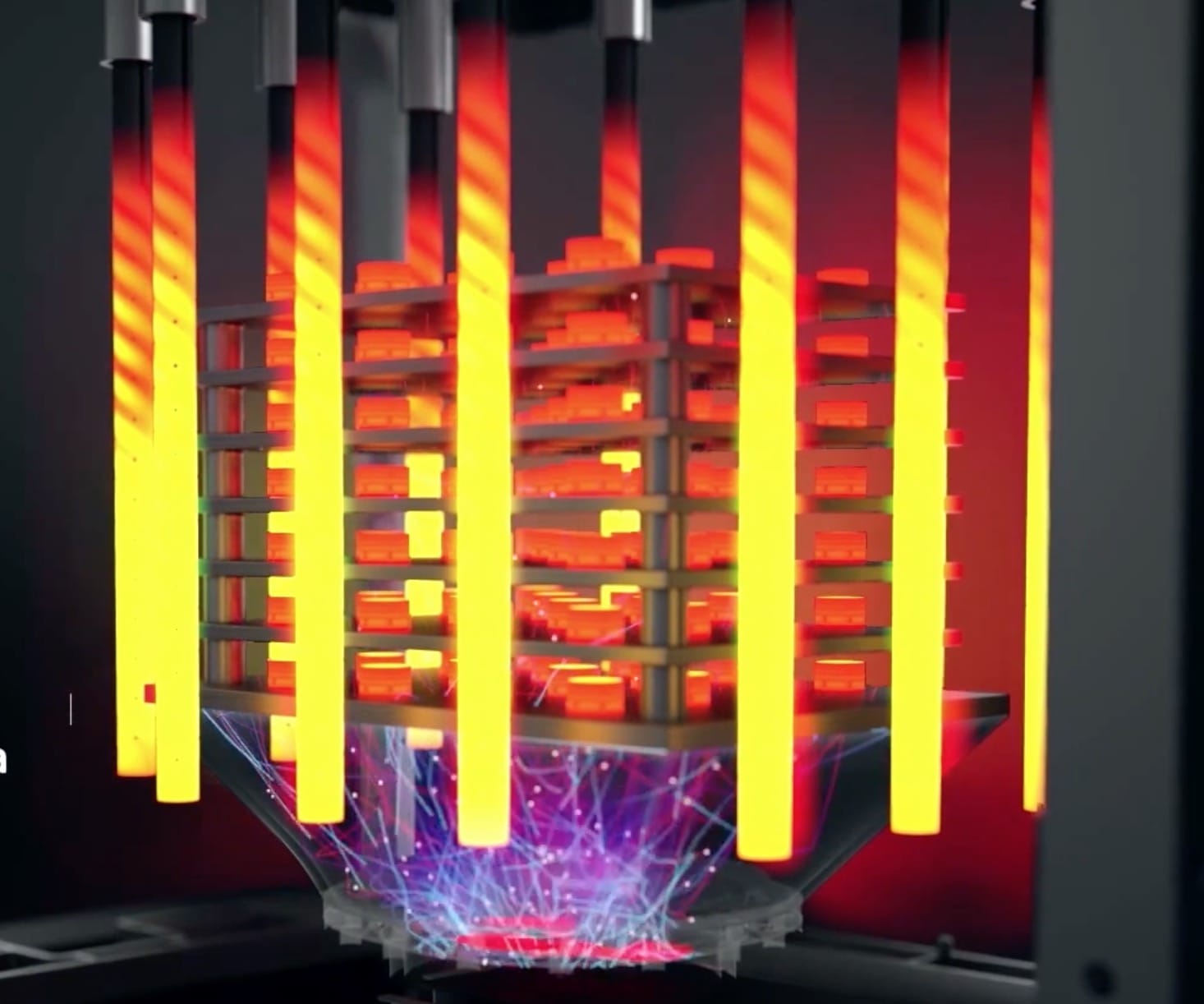

The “brown” parts created in this way are then subjected to a furnace, similar to the Studio process, to remove binder and fuse the metal particles together. However, the Production system’s furnace uses a hybrid of heat and microwaves to very rapidly sinter the parts.

Desktop Metal lists a large variety of materials, as they are using previously known materials from the metal injection molding industry. They say they can 3D print over 200 metal alloys, for example. It’s not clear whether these materials are all available for the Studio machine, but they very likely are to be made available for the Production machine.

In each case, the associated furnace is intelligent: it is set to provide the optimum heating profile for specific metals being used, making the process of finishing metal parts reliable and straightforward.

The most interesting aspect of the Production system is that it is highly efficient. The speed permits, according to Desktop Metal, parts to be printed at up to 100X faster than conventional 3D metal printers, and at far lower cost.

There are deep implications to various parties in the industry as a result of this announcement. There’s much to say, so expect to see some follow up stories in coming days.

Via Desktop Metal