This week’s selection is the fun Marblevator Baby Steps Revisited by Oklahoma-based Greg Zumwalt.

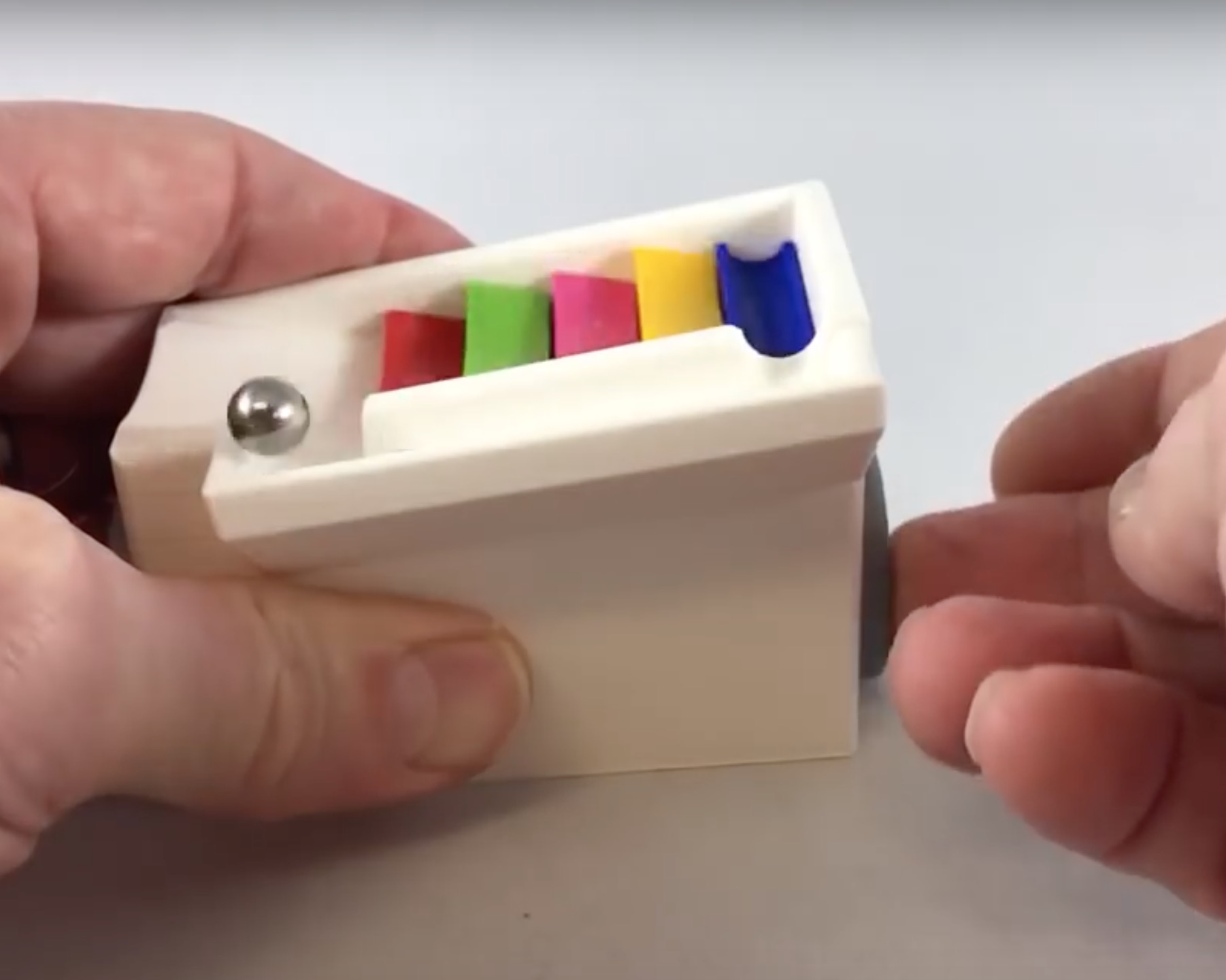

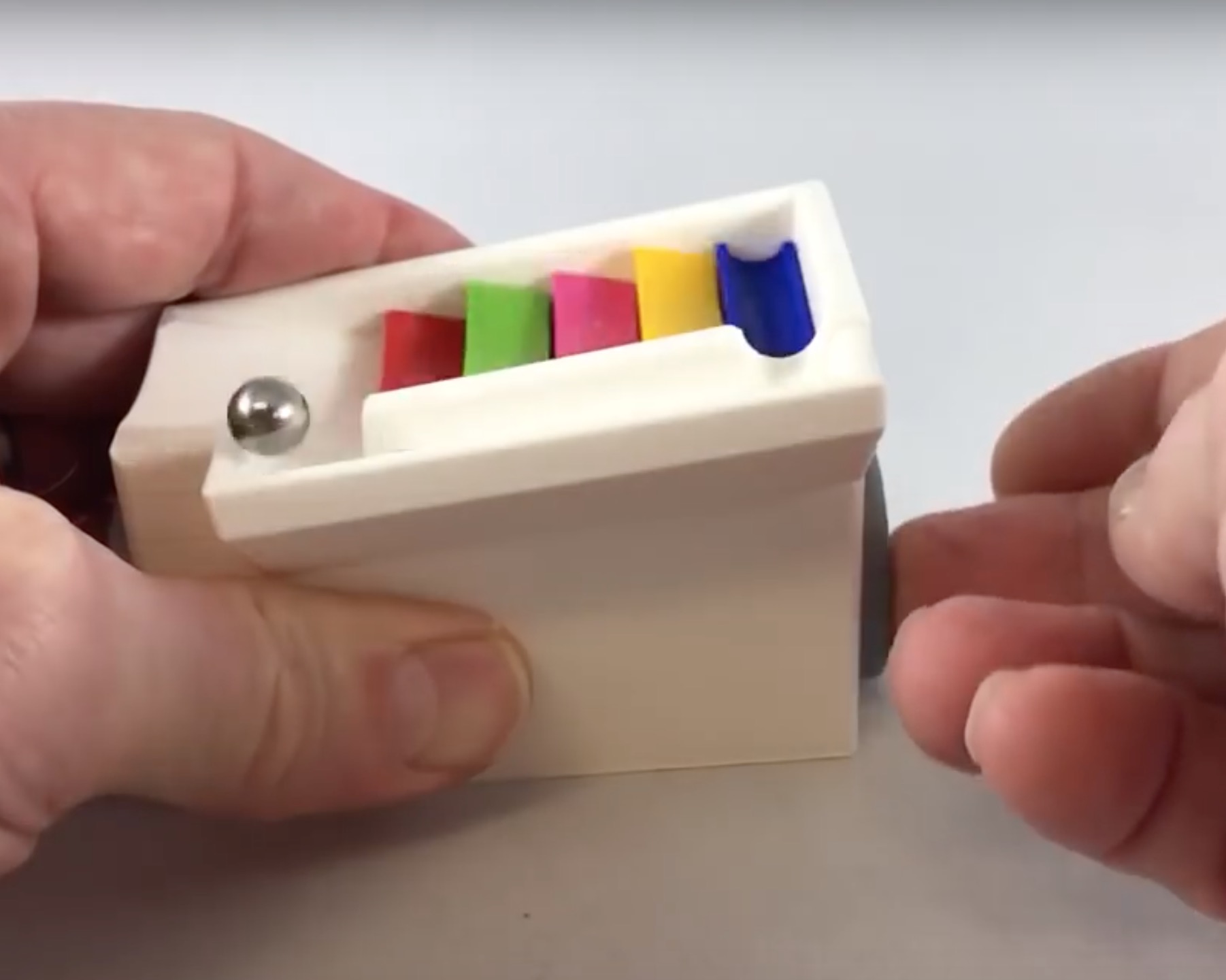

The Marblevator is an amusing device that implements an endless walk up some steps by a marble. While it may appear to be a perpetual motion machine, it’s actually powered by a hand crank, which powers a hidden camshaft.

The video shows how it works:

While it does look like a lot of fun, constructing this item will pose some challenges, as it includes a number of parts.

There are eleven part types in all, some of which must be printed twice to create the complete inventory required for assembly.

But this is a mechanical device that has many moving parts that must be well coordinated. Zumwalt recommends carefully preparing the parts after printing but before assembly to ensure they operate smoothly:

Prior to assembly, test fit and trim, file, sand, etc. all parts as necessary for smooth movement of moving surfaces, and tight fit for non moving surfaces. Depending on the colors you chose and your printer settings, more or less trimming, filing and/or sanding may be required.

Carefully file all edges that contacted the build plate to make absolutely sure that all build plate “ooze” is removed and that all edges are smooth. I used a flat jewelers file and plenty of patience to perform this step.

One of the best parts of this design is the small compartment to hold the marble at the bottom of the case. There’s a sliding cover with easy-to-hold tab to access this compartment. The design works because attention was paid to the use of the device and a possible failure mode, a missing marble, has been avoided because of this.

This project should be doable on virtually any 3D printer, and the files are available at no charge from YouMagine.

Via YouMagine