With all the hullabaloo regarding what’s called “continuous” 3D printing these days, it seems that EnvisionTEC holds a patent for it.

What is “continuous” 3D printing? It’s a process used in certain machines when 3D printing in resin. As you may recall, resin 3D printing is accomplished when a UV-light source selectively illuminates resin, causing some solidification to occur.

A problem encountered by many resin machines is that the illumination is from the bottom of a transparent resin tank to ensure a flat illumination surface. The newly fused resin also fuses to the tank itself, resulting in a tedious “peeling” process to unstick the fresh layer before moving on to illuminating the next layer.

Several companies have developed various approaches to solving this problem. The most notable is Carbon, whose oxygen permeable tank bottom chemically alters the resin at the tank edge to eliminate sticking entirely. Other companies have used unusual tank surface materials or adjusted their light engine to achieve similar results.

The really interesting thing is that when there is no required to pause for a “peel”, you can print continuously.

Instead of jumping up layers step by step, the Z-axis can simply slowly grind up in a continuous manner. By similarly continuously varying the light projection pattern in a coordinated manner, the print occurs continuously, without any layering effects. During printing, the light source is not turned off and remains on, simply adjusting the shape of the illumination as the print proceeds.

It’s a brilliant approach and should become very popular, not only for print quality, but because the prints can be much faster, although all machines are limited by the liquid flow of resin in to the cavity formed by the lifting print.

While these exciting new approaches are marketed strongly, we’ve learned that EnvisionTEC, a long-time manufacturer of resin-based 3D printing gear, apparently holds a patent on a form of continuous 3D printing. The patent, “Continuous generative process for producing a three-dimensional object” US 7892474 B2, describes the process as:

The invention describes a process and a device for producing at least one three-dimensional object, a photo-polymerizable material is solidified by means of simultaneous or almost simultaneous exposure of a build area or partial build area in a building plane via electromagnetic radiation, wherein a distance between a support plate, at which the object to be generated is built, and the building plane is changed during at least one exposure phase.

It is possible according to the invention to solidify the three-dimensional object in a main direction during a radiation phase exceeding a current prescribed hardening depth, without interrupting supply of electromagnetic energy during the irradiation phase. Further, it is possible to control a current hardening depth of the photopolymerizable material during a building phase.

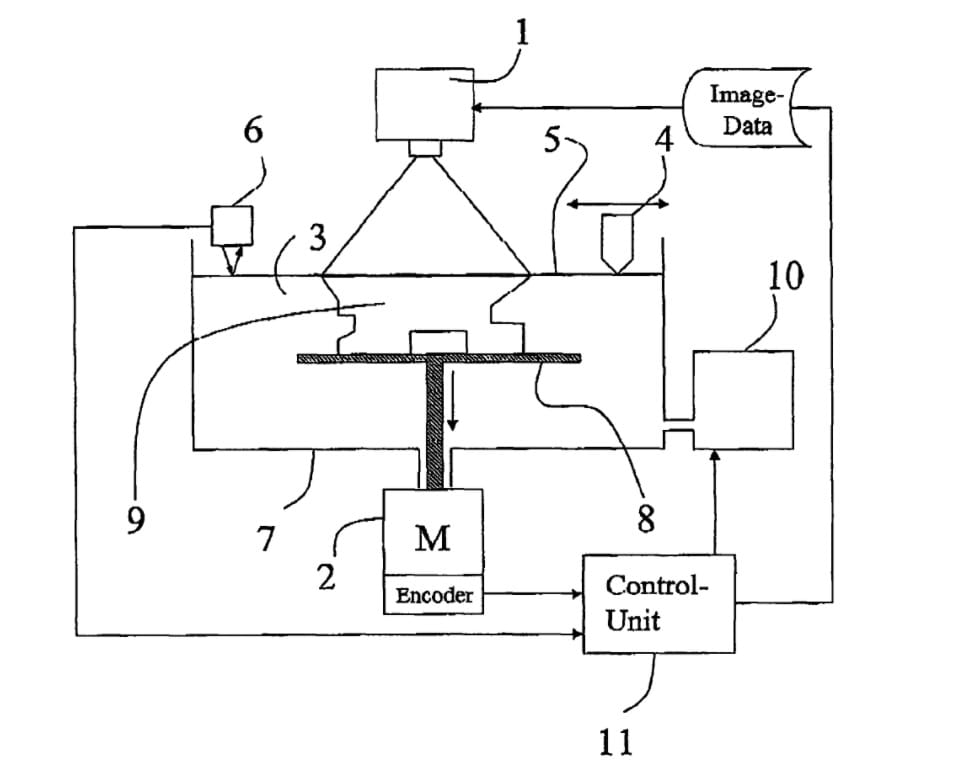

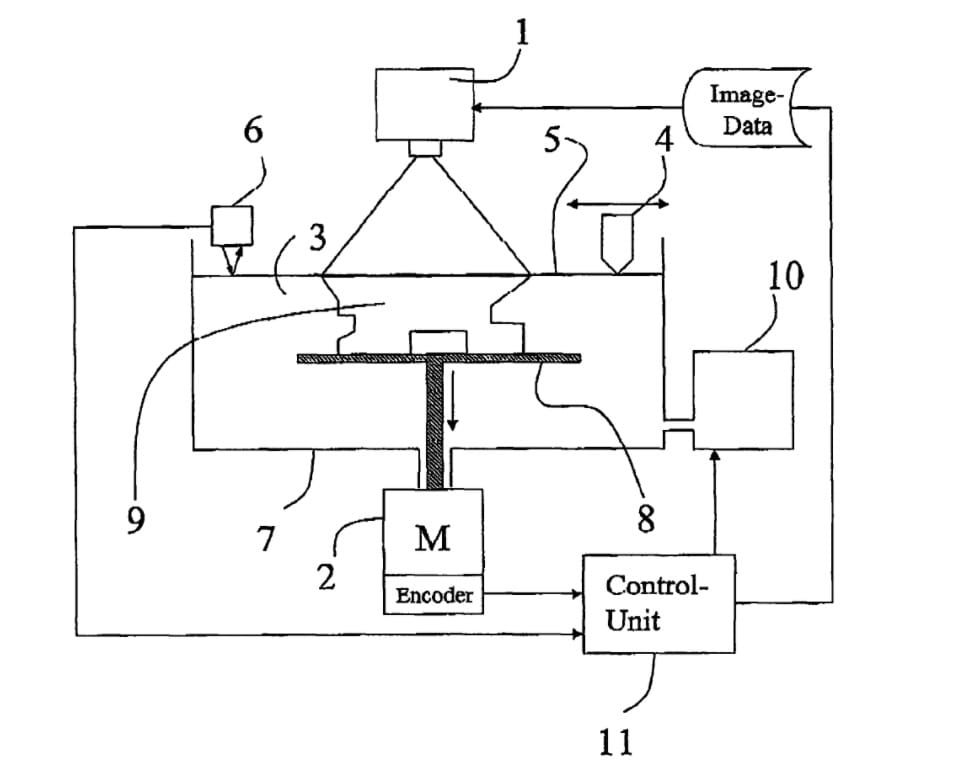

Now let’s see how they accomplish this. In the diagram from the patent above you can see how the system works. They’ve set up a light projection system of some sort at the top, which illuminates the liquid surface of the resin. The print bed is continuously lowered into the resin, where new layers are added at the top. When printing completes, the print is swiftly raised up through the resin and presented for removal.

The EnvisionTEC patent was awarded in 2006, and they should have the standard 20 years of exclusivity, meaning this tech would be available to others some time in 2026. Only 9 years away!

One thing I immediately notice is that the manner of EnvisionTEC’s continuous process differs from most other processes in that it is done from the top down, whereas most of the other continuous print processes work from the bottom of the tank up.

Because of this, I strongly suspect there will be no incidents of infringement as the processes appear to be significantly different, although with similar results. Don’t expect EnvisionTEC to be suing Carbon, for example.

However, there is at least one company that does in fact use the same top-down resin printing approach: Gizmo 3D Printers. The Australia-based company produces low cost machines that can indeed print continuously; we witnessed it doing so first hand last year.

I have no idea whether EnvisionTEC considers Gizmo 3D Printers’ activities an infringement, but it could be possible due to the similarity of process. However, that’s a matter for lawyers to investigate as slight differences can sometimes invalidate an infringement case.

Regardless, I’d like to see more machines using continuous 3D printing, because it’s a better way to make things.

Via Google Patents