Open source desktop 3D printer manufacture Prusa Research introduced a fascinating new feature in their slicing software that attempts to resolve the eternal trade off between quality of print and print speed in 3D printing.

Normally, you select a single layer height for the entire print. The 3D model is sliced into layers of that size and all are printed equally. However, if the layer size is small, you get a finely detailed print that takes forever to complete; while a larger layer size provides a quick, rough print. There’s no in between unless you select an intermediate layer height that offers mediocre speed and mediocre quality, hardly an optimal result.

Now Prusa Research has provided a freshly modified version of Slic3r, the open source 3D print slicing tool, that includes what they call “Smooth Variable Layer Height”, or “SVLH”. The idea is that the layer height can change dynamically during the print operation. If that’s possible, then you could increase the layer height for vertical sections where detail is unimportant, or decrease the layer height for sections requiring finer detail.

This is particularly important for gradual sloping surfaces, where a very visible “stair stepping” effect often occurs.

The concept is an old one, but for some reason it hasn’t been popularly implemented. Prusa explains:

The idea to vary a layer height to improve the finish of sloping surfaces is certainly not new. A paper by Pandey, Reddy and Dhand 2003 gives an extensive overview of algorithms to vary the layer height to limit the surface roughness, Florens Wasserfall integrated automatic layer height into his experimental Slic3r in the year 2014 as a part of his diploma thesis and Autodesk has shown their flavour of the variable layer height algorithm during the last year.

Josef Prusa believes their implementation is the only one that currently is available for general use, saying:

I am very thrilled we were able to produce the first practical solution for FFF 3D printers with such stunning results.

And the results are quite dramatic. This video shows how it works:

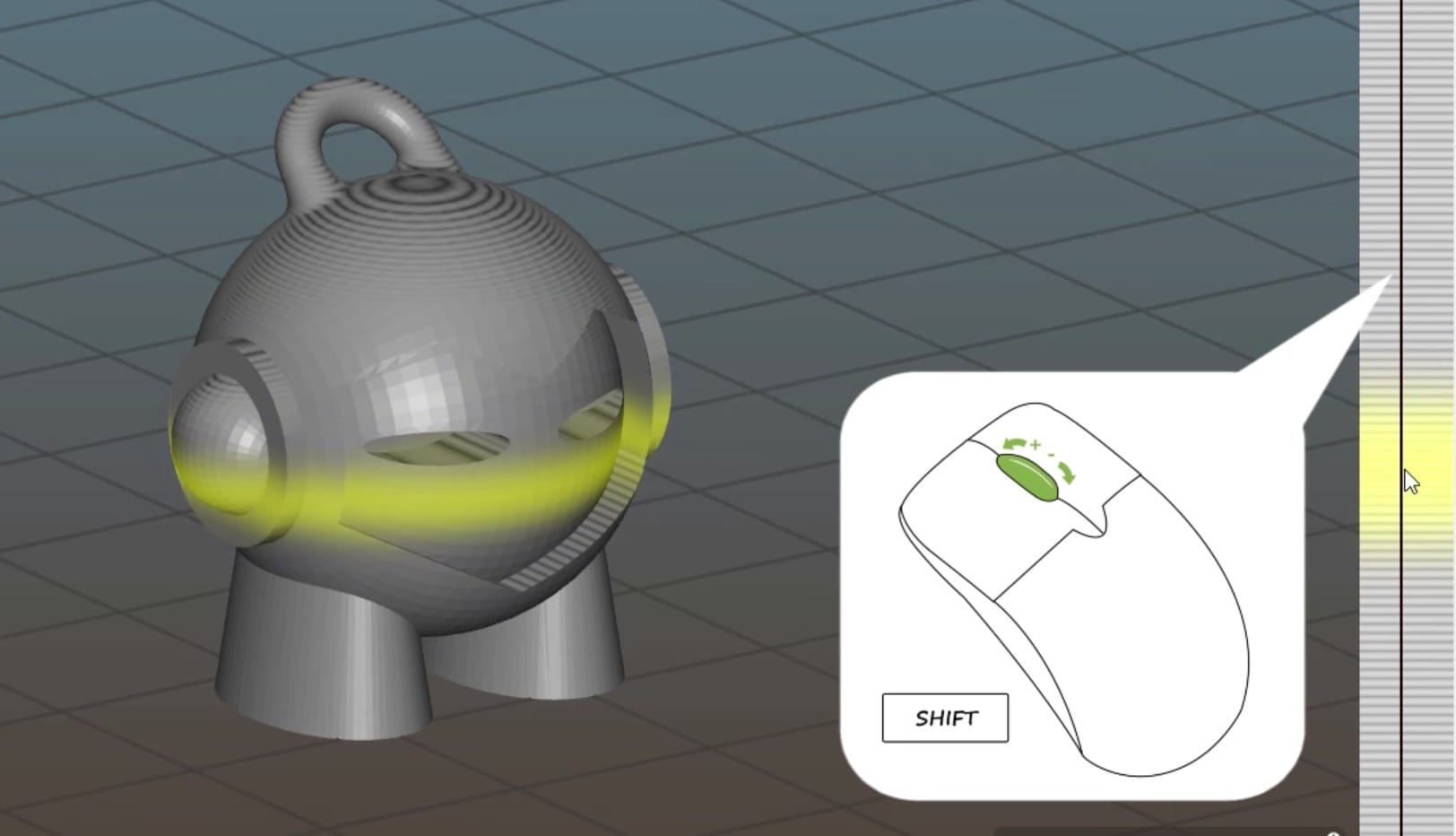

The differing layer heights are not generated automatically, but rely on the operator to select sizes for different vertical sections of the print as seen here.

This image shows the different quality levels and the corresponding print times. As you can see, the SVLH print wasn’t quite as fast as the fully coarse model, but it provided great quality at a speed faster than the finely layered print.

The software is available now at Prusa Research. Get smoothing now!

Via Prusa Research