Notable 3D print retailer iMakr has begun selling a desktop 3D food printer to consumers. Is this a wise idea?

3D food printers have been around for quite a while now, as I have seen experiments from at least seven years ago. Since that time there have been a few experimental food printers and even a couple of commercial units. Even 3D Systems marketed a 3D food printer of sorts (it printed in sugar) for a while. But most of these are now gone.

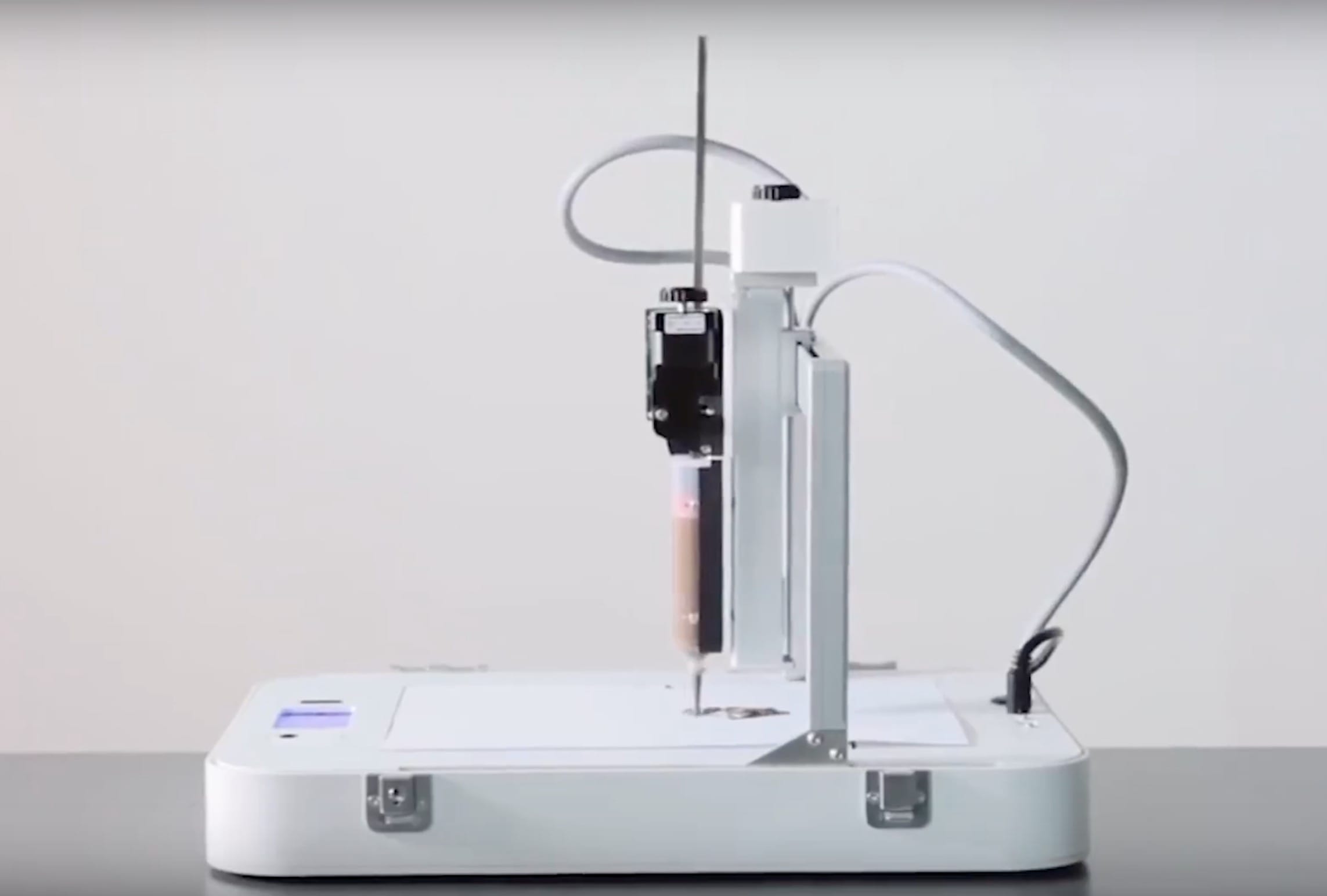

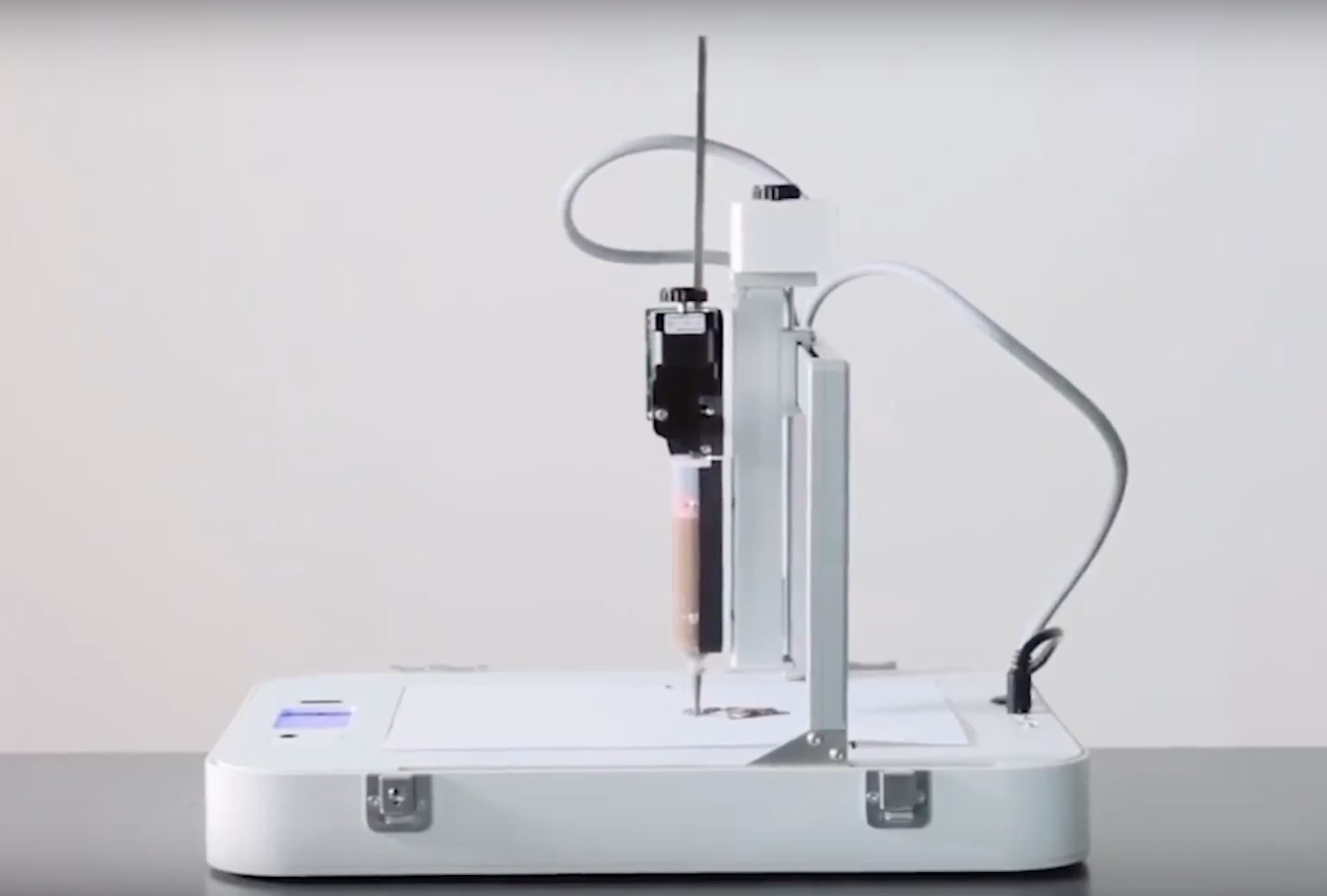

Now we see that iMakr now offers such a device, one of the very few food-capable machines to appear on their shelves. (Another would be the Choc Edge 3D chocolate printer). The ByFlow Focus is the device in question.

At its core, the Focus is simply a portable 3D printer that can print in both normal plastic filament or extrudable substances with its alternate syringe-style extruder.

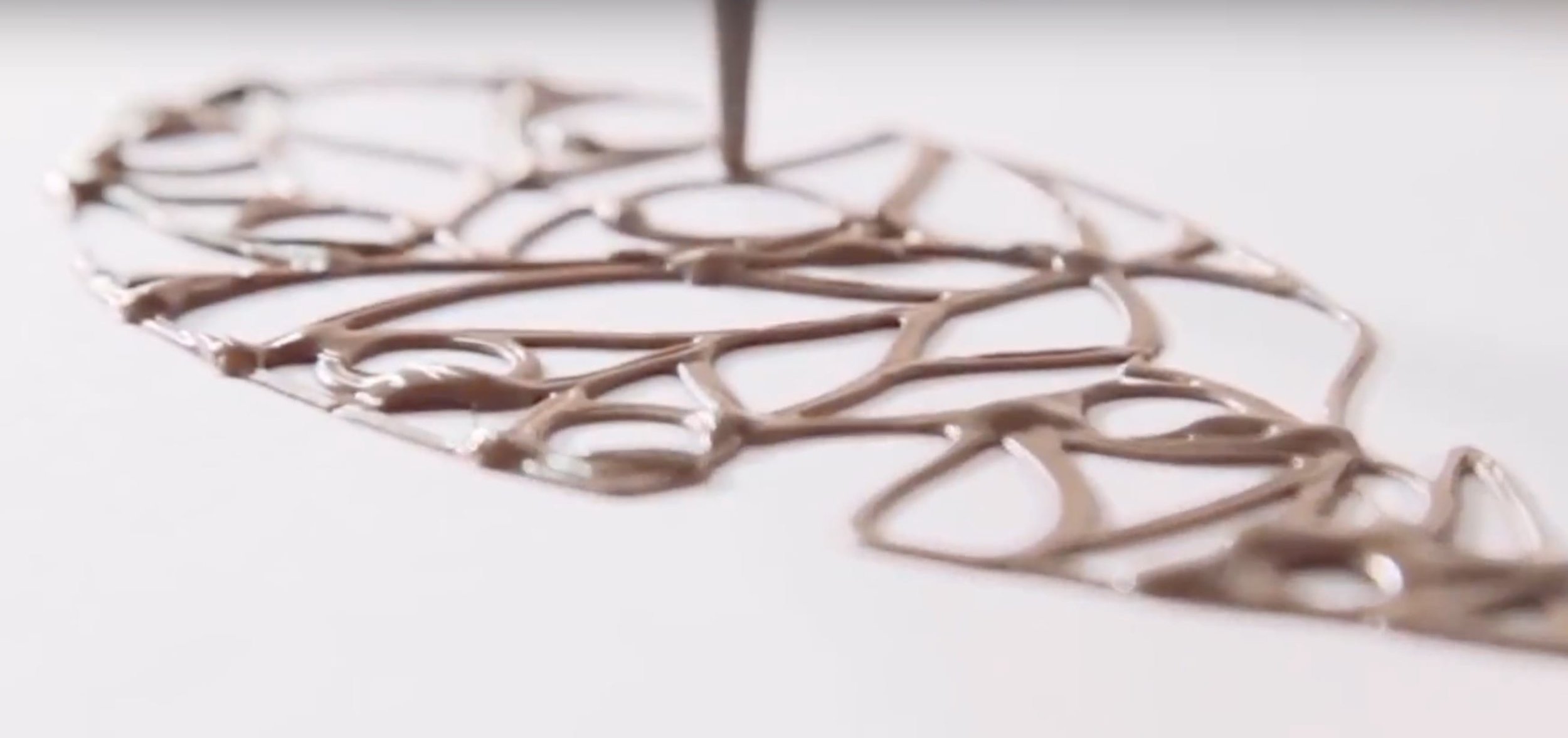

It’s through this alternate extruder will food emerge. Paste, really, which includes silicone, but also many food pastes, such as dough, heated chocolate, peanut butter, etc.

Food prints are usually impractical for normal use, as the effort and time required to 3D print a food item often outweighs the value. For commercial operations who make more complex items for money, it may be a different story, however.

The Flow includes a build volume of 208 x 228 x 150mm and includes a glass plate, which would be practical for food printing. Aside from the syringe extruder and portability, the device appears to be a typical desktop 3D printer with the usual features.

But what’s interesting to me is that iMakr is positioning this as a portable 3D food printer, which it is – but it’s really a plastic 3D printer. It could have been sold as a 3D printer with food attachment, but no, that’s not how it was billed.

I’m wondering if iMakr is doing a bit of a marketing experiment here, attempting to test the interest of buyers for 3D food printing equipment? This machine is more capable than the Choc Edge, as it can print a much wider variety of food pastes.

While the machine may provide the capability of extruding food, there still remains the barrier of 3D food models and recipes for the unit. There are few sources of 3D food models available, leaving the development of 3D models for this purpose to the operator, who hopefully has some basic 3D design skills and software. iMakr has provided one such recipe, but you’d need a great deal more to make it practical for the general public.

Will this product sell? I’m very curious, as it carries a rather hefty USD$3,299 price tag, well above that of comparable plastic extrusion units. Those other units don’t have the food capability, however, making that feature worth USD$1,000 or more.

Historically, however, iMakr has tended to sell 3D printers that were of good quality, as their process involves very extensive testing of any unit provided by a manufacturer before it hits their product shelves.

Is the public ready for 3D food printing? We’ll find out.

Via iMakr