Key to HP’s Multi Jet Fusion (MJF) 3D printing technology is its open materials platform, wherein materials partners can develop powders specifically for 3D printing with MJF. Not only is this a unique concept for printer manufacturers, but it could also be crucial for the widespread adoption of MJF in the broader manufacturing industry.

While treating ENGINEERING.com to a tour of its Corvallis, Oreg., site, HP used the opportunity to introduce us to what may be the world’s first Material Development Kit (MDK) for 3D printing. Although it is modeled after a software development kit, an MDK isn’t as straightforward as providing source code to a potential material partner.

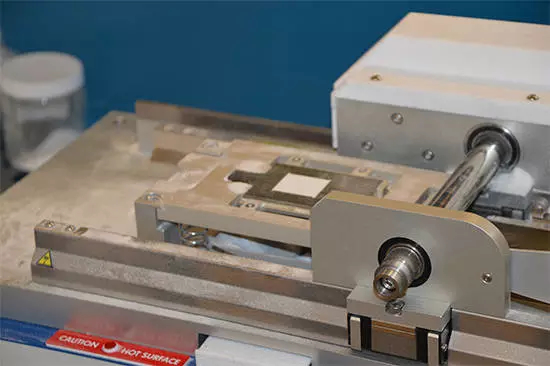

The MDK is actually a piece of hardware built by HP partner SIGMADESIGN for the purposes of testing powders before submitting new materials to HP for certification and sale in the company’s marketplace. At the Corvallis site, we were able to get a look at the MDK as well as future developments associated with the HP open materials platform.

The MDK

Product engineering and design company SIGMADESIGN was among the first customers to receive an HP Jet Fusion 3D 4200 3D printer. As such, the company has firsthand experience with MJF technology and its work in product engineering enabled SIGMADESIGN to develop the MDK for MJF.

Bill Huseby, president and CEO of SIGMADESIGN, said of the MDK, “Many companies, both large and small, do not have the internal capabilities to execute their 3D printing vision as quickly or as broadly as they’d like. We are proud to provide world-class foundational tools such as the MDK and in-depth design expertise for organizations ready to innovate using HP Multi Jet Fusion technology right now.”

The MDK, which is available for preorder from SIGMADESIGN for $24,150, provides just the first step to validating a material for use with MJF. The system simulates the rolling mechanism featured in MJF 3D printers that makes it possible to test how well a powder spreads across the build platform. The MDK disperses the powder across one of a variety of test coupons that represent the layer thicknesses possible with MJF (five coupons from 0.1 mm to 1.0 mm).

Although the dispersion may be partially determined by the human eye, SIGMADESIGN also developed a $6,725 vision system accessory that quantifies the average optical density and uniformity of the MDK’s powder spread. This provides a much more accurate calculation of how well the material can be spread by an actual HP system.

Read more at ENGINEERING.com