There are large and growing number of 3D metal printers on the market today, but none of them are exactly like BeAM.

Most of the 3D metal printing options available today use a relatively standard approach of focusing a high-power laser on a flat bed of metal powder, selectively fusing layers until the object is completed. I’ve recently seen multiple new companies introduce such equipment and it’s almost becoming difficult to distinguish between them as they are so similar in capability and process.

But then there’s BeAM, a five year old French company based in Strasbourg.

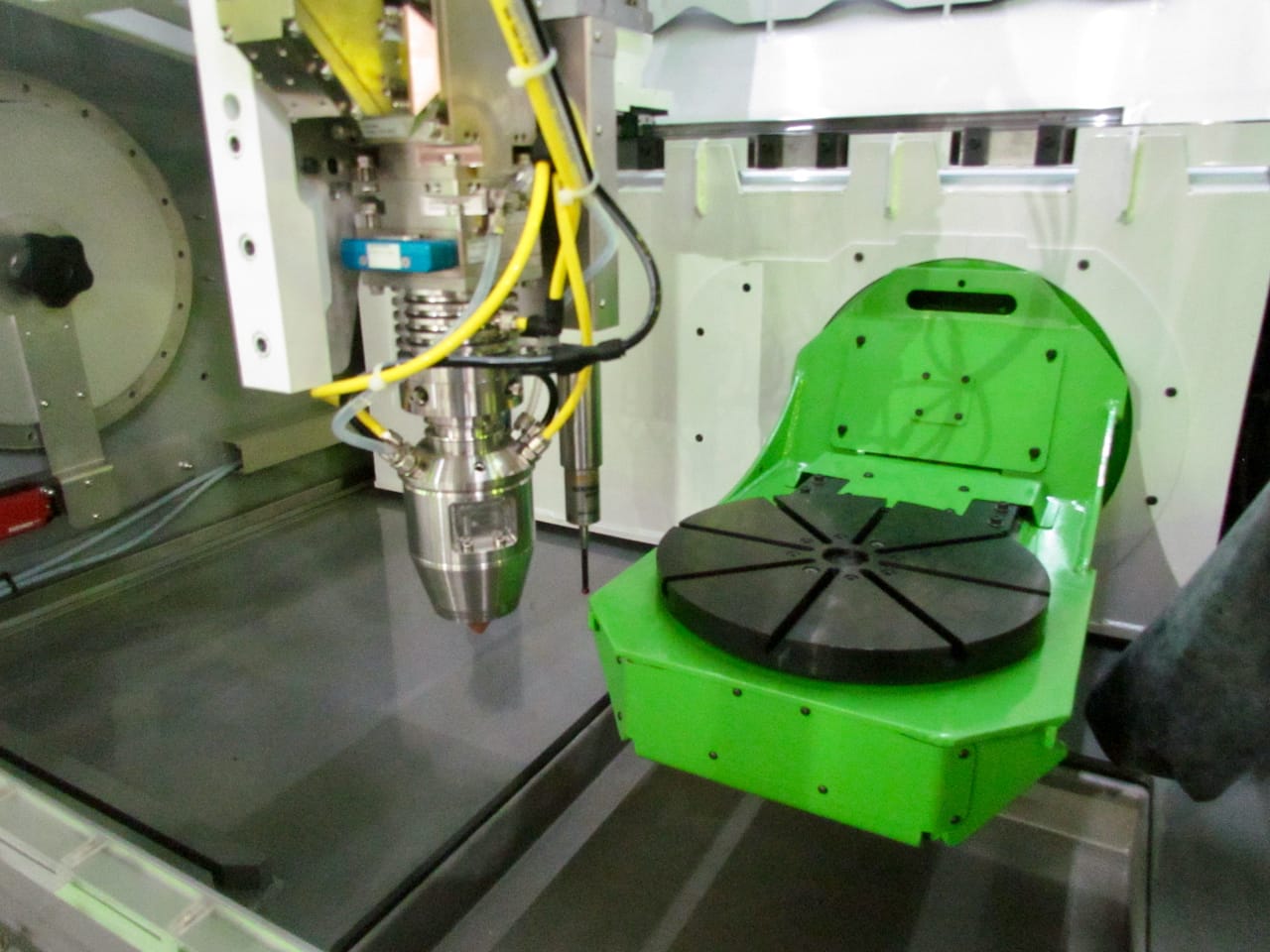

The company’s machines use an entirely different approach, although it still uses metal powder. Their laser metal deposition process, called “CLAD” is unique. It involves spraying metal powder precisely at a target location, where simultaneously a high-power laser beam also arrives. This melts the powder instantly where it fuses into shape. Thus there is no need for a powder bed; the powder is delivered only to the object’s location.

The BeAM system has another very cool advantage: a multi-axis CNC system moves the in-progress print dynamically to create the shape. You can see how this works in their video:

This approach has a very significant advantage: there is no need for support material! You simply move the object to the right orientation for each split-second of printing. This works well because the printed metal is extremely stiff and does not flop around while being reoriented, as thin plastic might.

Why is this important? Because in other 3D metal printing processes support structures drain off heat during printing and must be carefully designed to ensure the appropriate amount and speed of cooling of the fused metal powder. There are no such problems with BeAM’s system.

An interesting side effect is also enabled by this CNC arrangement: it’s possible to repair complex metal parts with the right GCODE. A hole could be filled, for example, by mounting the broken part on the print bed and the BeAM machine would move the part into the correct orientations for the CLAD nozzle to patch it up. You cannot do this with a powder-bed process.

One challenge with BeAM’s process is that they apparently cannot print in aluminum. But other metals are certainly possible to print.

Among the many options for 3D metal printers, BeAM is definitely one to investigate.

Via BeAM