We knew this was coming, and now it’s here: Ability3D has launched a Kickstarter campaign for their very inexpensive 3D metal printer, the Ability1.

We spoke directly with Ability3D chief Ben Willard at CES to get his thoughts on the project in January, but from that conversation it was clear his company was nearing the launch of their product, which surely must be the least expensive 3D metal printer available.

The Ability1 uses a 3D metal printing process totally unlike the more typical – and vastly more pricey – powder processes of the established metal printing vendors. However, Ability3D’s process is not a rookie method that has yet to be proven. No, it’s actually the very well understood MIG welding process. In their concept, the welder is essentially transformed into a CNC machine that operates in a 3D space. Metal is gradually deposited in layers, much like other 3D metal printers.

The process is rather coarse, however, and as a result the Ability1 includes a simple milling system to trim off excess material on each layer as the print proceeds. This ensures the prints are of reasonable quality.

The results are impressive, but perhaps not of sufficient quality to compete with, say EOS or Arcam to make certified flight-ready aircraft components. But that’s not the goal of this project; no, instead Ability3D is attempting to make an affordable desktop 3D metal printer that everyone can use for simpler projects.

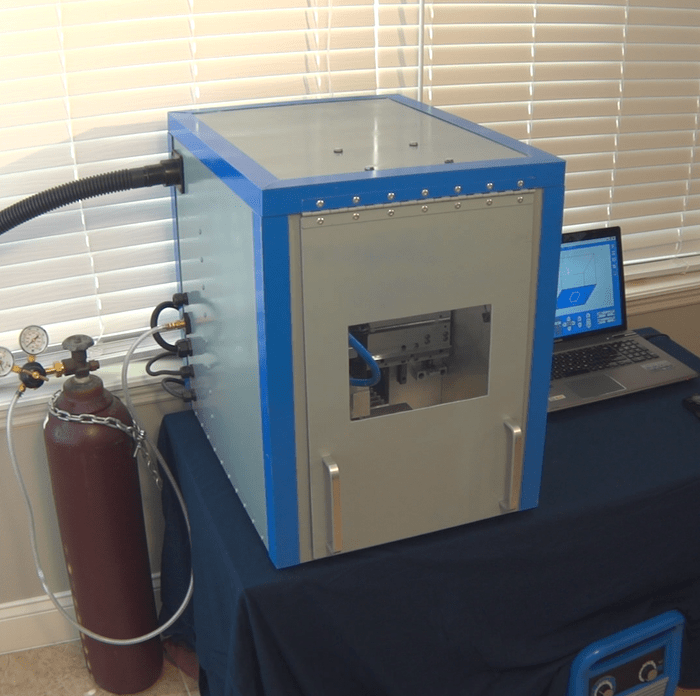

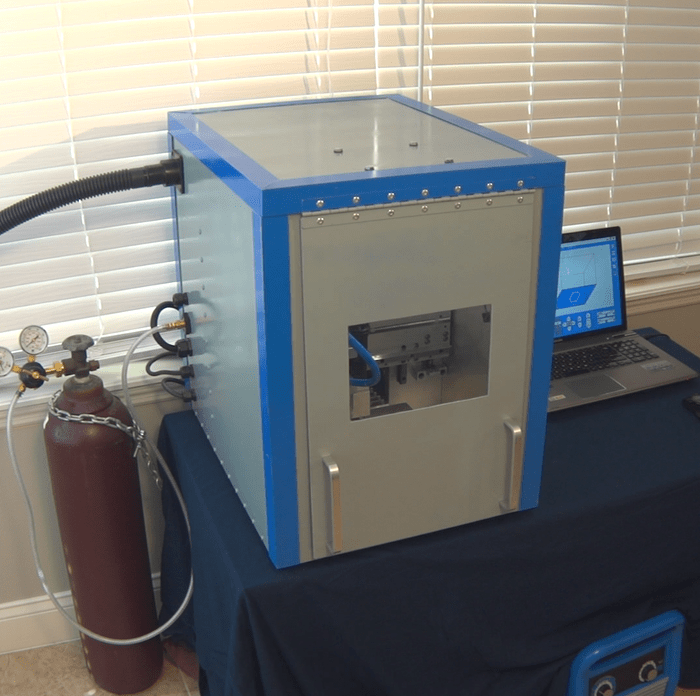

The design of the Ability1 is robust; it’s made mostly of solid metal and contains a number of safety features, such as an eye-safe viewing window to supervise operations. The machine also includes lockouts to power off operations should the door be opened during printing.

As the Ability1 uses MIG welding technology, it requires a gas source, so you must bring your own cylinder to attach to the Abiilty1. This should not be a problem as such gas is very commonly available almost everywhere. I wouldn’t be surprised if many Ability1 operators already have gas cylinders in their workshops already.

The Abilty1 includes a airflow system that draws in fresh room air and blows out welding exhaust through a tube that you must route to the outside atmosphere. This may restrict your potential installation locations somewhat, but is required for safety.

Materials for this machine are actually plentiful and inexpensive: you simply use MIG welding wire, which comes in a wide variety of metals at low prices. A typical price might be, say, USD$50 for 15kg of spooled mild steel material. That price, around USD$3 per Kg indeed less expensive than powdered material for the large-scale 3D metal printers, which can run up to USD$500 per Kg. The Ability3D approach could be literally 100X cheaper to operate.

The machine is not quite complete as ordered; this is a very early-stage of the device. You must supply your own computer to drive the machine.

Ability1: 3D Print Real Metal Parts At Home!

Ability3D is raising funds for Ability1: 3D Print Real Metal Parts At Home! on Kickstarter! 3D Printing real metal parts at home is finally possible with Ability3D’s 3D Metal Printer: the new Ability1

And there’s another problem: there doesn’t seem to be software available yet. And that’s one of the main purposes of their Kickstarter campaign; to raise funds to engage a software team to develop programs to convert 3D models into the correct GCODE for the Ability1. This is obviously essential for the success of the project, but at the same time is a problem that is likely solvable with the right team.

In the meantime, all the prints you’ve seen from the Ability1 and it’s prototypes have been based on handcrafted GCODE.

I’m not overly concerned about the lack of software, as it can be certainly be created and will likely enable a significant refinement in the quality of the output.

For now, Ability3D hopes you will sign up for a machine at a starting price of USD$2,799, which is a ridiculously low price for a 3D metal printer. They have set a rather ambitious goal of USD$640,000 for the raise, and it’s an “all or none” project. This means that if they do not hit that target it will not proceed.

However, that lofty goal is likely what is actually required to get this project completed, so I suspect they’ve done some careful planning here. That’s a good sign.

They hope to deliver the machine in October, but I must caution buyers that this is a Kickstarter project from a small startup company. I recommend you review our checklist for such situations.

It is possible they may incur a delay as they develop the software. However, software development is a continuous process and I expect things to gradually improve as the months tick by.

If this project succeeds, we will see an entirely new set of 3D metal printing operators: those who were unable to afford the very expensive traditional equipment.

Via Kickstarter and Ability3D