Professional desktop 3D printer manufacturer Type A Machines announced an interesting contract manufacturing relationship that could indicate their plans.

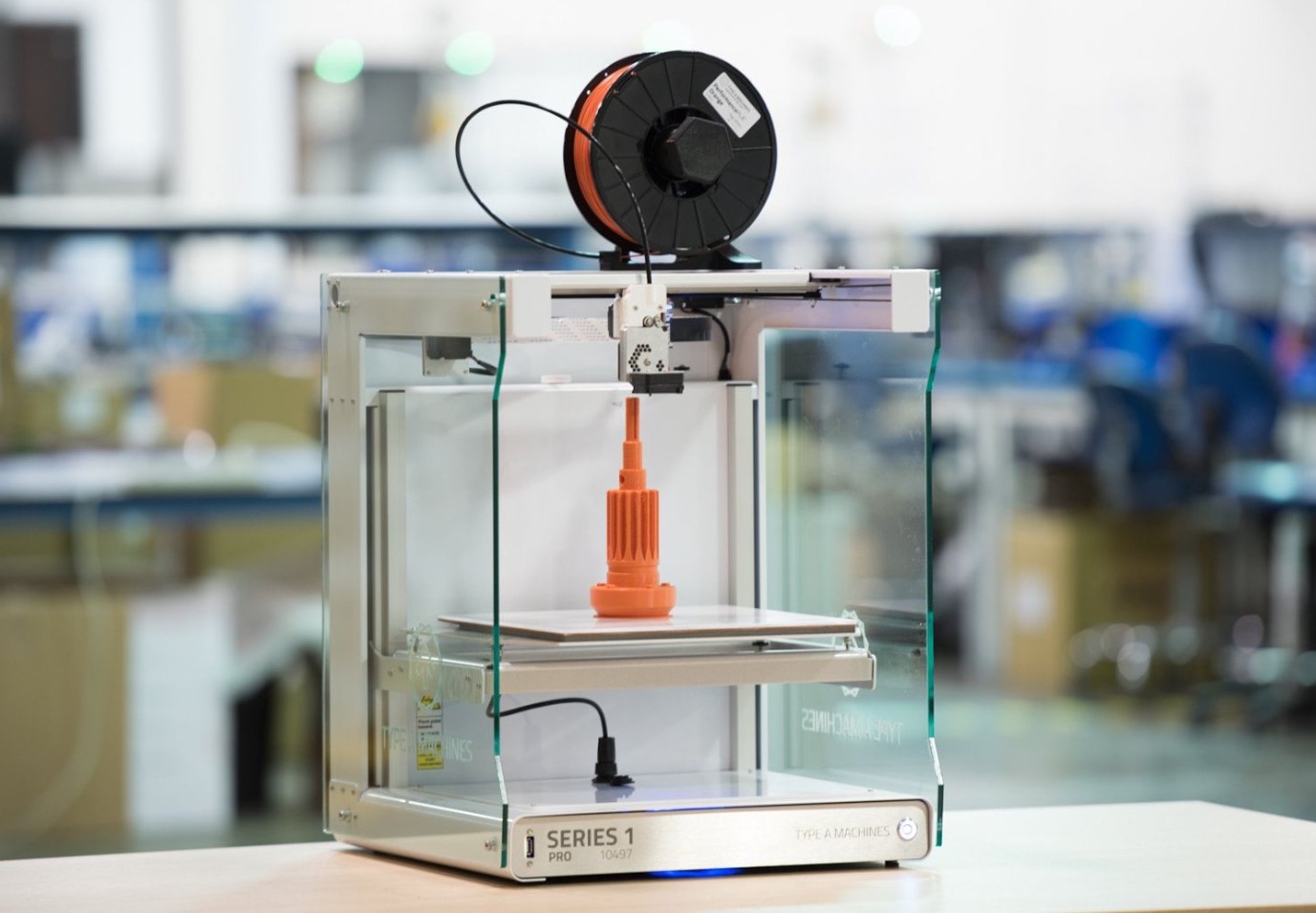

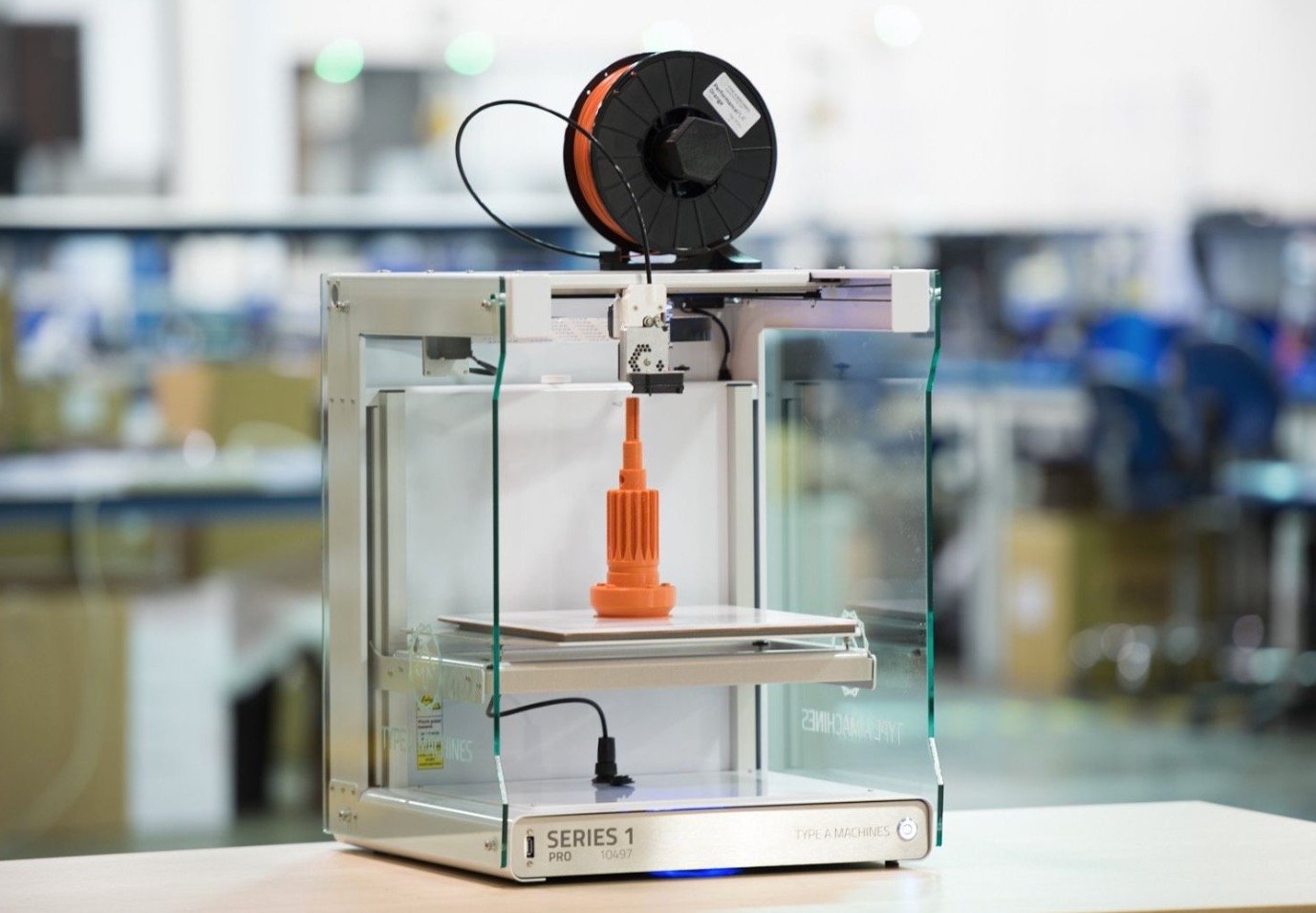

The startup company has been around since 2012, I believe, and has been selling equipment since at least 2013, with their Series 1 machine. Their latest machine is the Series 1 Pro, a more advanced version.

But it’s not machines we’re talking about today. Nope, it’s instead how they’re made.

Most 3D printer manufacturing startups commence operations by simply assembling the machines in-house. At this point in the company lifecycle, many companies fail because they don’t understand how to make machines in quantity. It’s a special skill that isn’t frequently found in two or three person startups. But Type A Machines covered off that step easily and has grown to today.

But what’s more interesting is the next stage that a company must go through: scaling up. It’s at this stage a company must transform itself into one that’s capable of delivering larger quantities of equipment on a much more consistent basis with known high quality.

Very often this is another stage where companies fail. It’s because while the company has developed a successful in-house manufacturing process, they realize that they are not capable of expanding their operations to higher scales, and thus seek some outside party to help them achieve their production goals. Some call it outsourcing, others call it contract manufacturing.

Essentially, the company has a professional manufacturer do the work for them. In theory this should be a great benefit, because the inevitably larger contract manufacturer will have: more and powerful making equipment; shifts of trained workers to make things; deals with suppliers and shippers that could not be obtained by smaller startups.

It’s a compelling reason to outsource your production: more, potentially better and cheaper.

However, like the challenges of initial manufacturing, this stage also requires particular management skills to properly organize and supervise the work with the manufacturer. Those are different skills than can be found in a typical small in-house manufacturer. Consider the case of MCOR, who recently engaged a professional manufacturer to produce their Arke color 3D printer in our detailed interview earlier.

Some companies fail at this stage, like Solidoodle.

So it is very challenging to get this stage right. And it seems that Type A Machines is taking this step.

I don’t know all the details, as it’s not my business, but from the surface it appears Type A Machines is doing things properly. They’ve engaged BriteLab, a San Jose-based manufacturing operation to build their equipment.

If they succeed, then they’re in an enviable position. Should the market for professional desktop 3D printers explode – and it might given what I’ve been hearing – their contract manufacturer will be able to churn out quality units on demand. They should never fall short of units to sell, while other in-house operations may be challenged to do so if demand rises steeply.

Another interesting benefit from using a contract manufacturer is a change in the quality of the device. A good contract manufacturer will have tremendous experience in building all kinds of devices efficiently and effectively. Their knowledge would be applied to the Type A Machines’ design and perhaps adapt it to streamline production, make the machine more reliable and potentially other improvements.

I think this is good news all around – unless you’re a competitor of Type A Machines.

Via Type A Machines