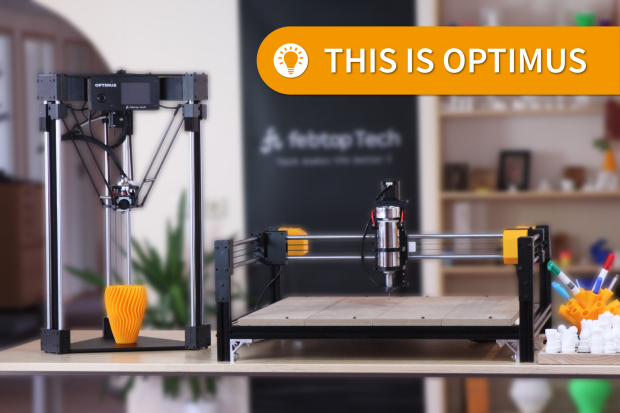

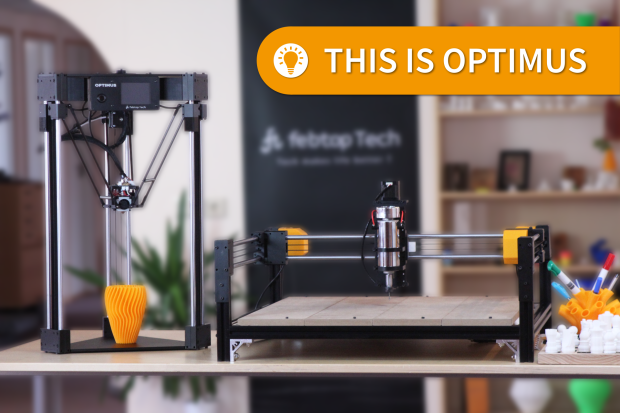

Today Febtop Tech launches the Optimus, one of the few combo machines that combines 3D printing with other making processes.

In the case of the Optimus, the device is able to perform laser engraving and CNC milling functions, but there are some interesting steps to get there.

The 3D printer function of the Optimus is provided through a pretty standard-looking delta 3D printer setup, which has a very healthy build volume of 240mm diameter by 300mm tall.

3D printing can be done with standard 1.75mm filament in materials with melting point less than 295C, such as PLA, ABS, HIPS and others. The machine is also said to 3D print layers as small as 0.05mm, which is better than typical these days.

But this machine also laser engraves and CNC mills, but to do so is radically different than what you’d see in other combo units.

When I first read about this machine, I was very skeptical about the ability of a delta mechanism to provide the necessary “oomph” to power a CNC bit through some stiff wood through those indirect delta arms. But then it turns out you don’t actually use the delta configuration when milling on the Optimus.

In fact, what you must do is disassemble the delta and extract the key mechanical component and install it on a separate cartesian system that is capable of the necessary power.

Febtop Tech explains that this transformation can take less than ten minutes, but I suspect it will be longer than that the first time you try it. However, like anything, it will get easier the more you do it.

What’s interesting is that the system is self calibrating, making the transformation far less arduous than it could have been.

But why do this transformation aside from the power requirement? It’s also the build size: 3D printers tend to have relatively small build volumes compared to many laser engravers and CNC mills. This transformation takes that issue away by providing a much larger build volume for those functions with the separate table: 400 x 400 x 80mm.

That permits creators to engrave solid materials (or cut paper) to a much larger size than would be possible on a small 3D printer build plate.

The CNC function is apparently capable of milling some fairly substantial materials such as “woods, acrylic, ABS, machinable wax, brass and aluminum and more”. That tells me this machine is pretty powerful, as other combo units are sometimes not powerful enough to run the milling bit through such materials except at very low speeds.

In this video you can see how fast this machine can mill, as it slices easily through some acrylic.

Another very interesting feature is a smartphone app that provides instructions for the often tedious job of setting up milling operations. If you’re not familiar with milling you will need instructions and having them in your hand would be of great value. However, at this time it’s only available for Android devices. I expect they’ll launch an iPhone version soon. It even can automatically transform a picture from your smartphone into GCODE for milling or engraving.

The laser function operates on the same table as the CNC, but what I found most interesting is the laser power. Most combo units have underpowered lasers that result in excessive job times due to slow movement of the laser, but that’s not necessarily the case with this machine.

While the standard Optimus includes a minuscule 0.5W laser, you can upgrade to 2W (USD$59), 5W (USD$179) or a very usable 10W (USD$275). The 10W option would enable practical use for engraving large flat surfaces on the large separate table.

Pricing for the Optimus depends on the options selected. You could, for example, buy just the 3D printer for USD$979, but I’d recommend not doing so as there are other 3D printer options available if you only need that function.

You can buy a 2-in-1 unit for USD$1,070 and it goes up from there.

Again, I must caution readers to moderate their excitement as this is a crowdfunded project from a small startup company. As we’ve written oh-so-frequently recently, such scenarios do pose some risk for your purchasing dollars.

Via Indiegogo