Discussions with AIO Robotics reveal they’re working on some interesting motion systems for their ZEUS equipment.

I first wrote about the California-based company over a year ago, when I was totally impressed with their concept of storing education lesson plans and associated 3D models on board the machine, with automatic network updates. It was a brilliant idea then, and still is today. I’m not sure any other desktop 3D printer manufacturer is doing the same, perhaps because AIO Robotics has a very powerful processor in their unit that can handle the load.

In any case, our team dropped by for a visit to see what’s new and we noticed a couple of interesting things.

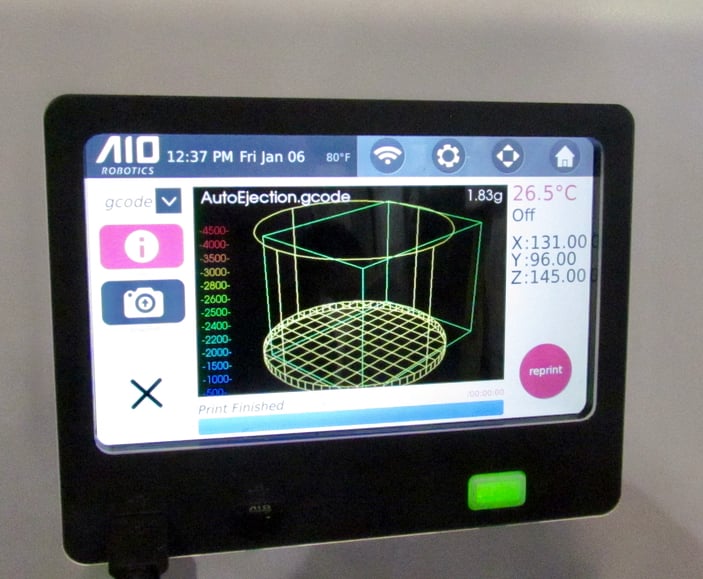

One was an “Auto Ejection System” that has not yet been released.

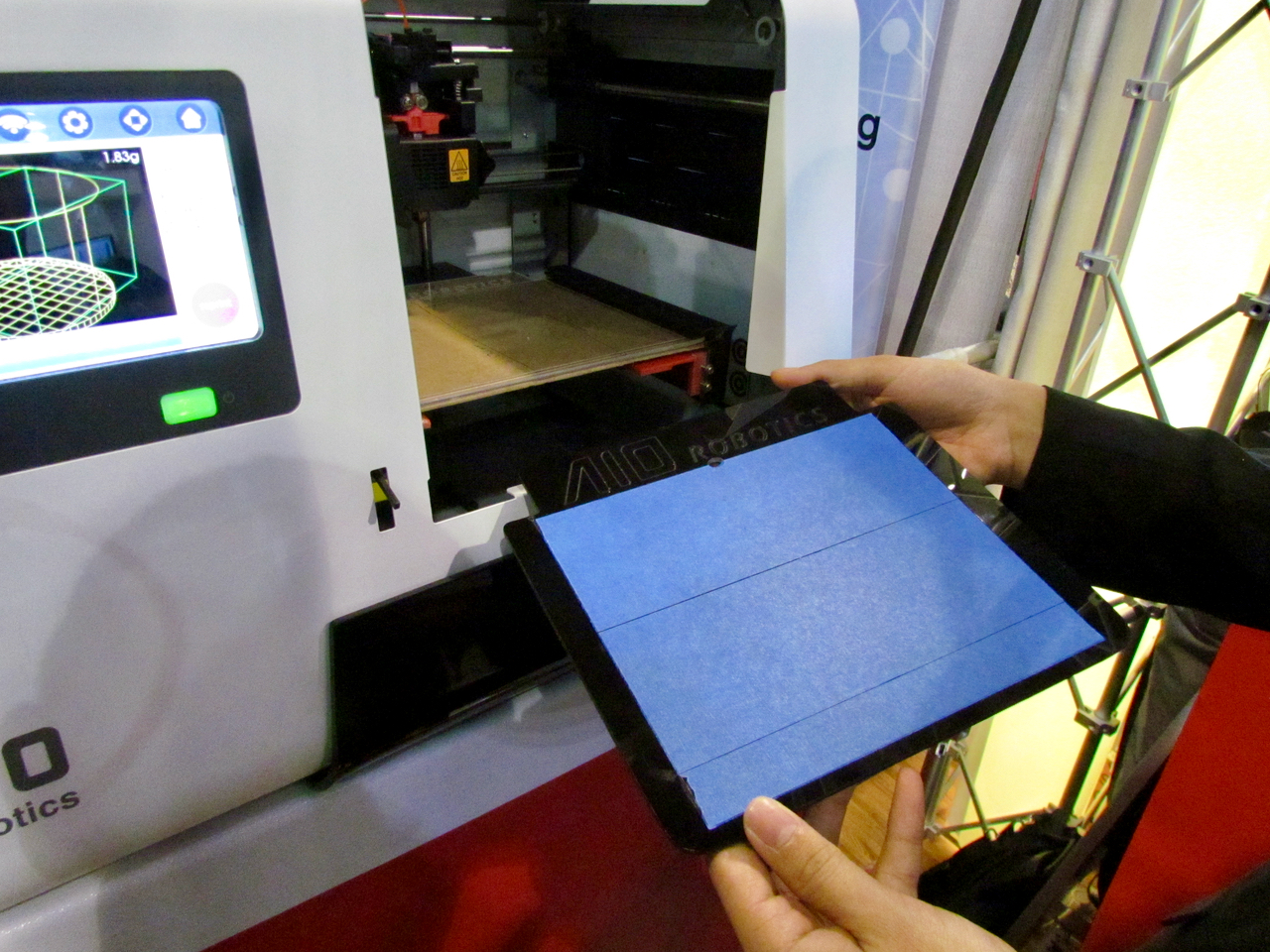

It’s an interesting concept. Evidently the machine will include a special holder for the build tray where up to three trays will be stored. The top tray is the one that will be printed upon.

When a print job completes, the top plate can be ejected and prints removed in an offline manner. Meanwhile, the machine has now exposed the second tray in the stack of three. The machine can then use its auto-leveling feature to detect the height of this new print surface and begin printing correctly once again.

It’s a very interesting concept, although it does not permit continuous printing – you can print up to three items using this approach.

Another curious thing I noticed was this circular print surface.

It’s actually a turntable, normally used for rotating an object for 3D laser scanning, which happens to be one of the standard features of AIO Robotics’ ZEUS machines.

But notice in this image that they are not 3D scanning: they are 3D printing! On a turntable. It wasn’t clear if the turntable rotates during printing, but if so, that would be a significantly different motion system for a 3D printer, requiring custom GCODE to handle the more complex movements.

As usual, AIO Robotics has something interesting to consider.

Via AIO Robotics