A new 3D printer project on Kickstarter hopes to capitalize on consumer 3D printing with a new approach.

The notion of a consumer 3D printer more or less fell out of favor after a few years of attempts to crack it by several major vendors. While each had initial (and ongoing to today) success with hobby DIYers, they ran into a brick wall when attempting to sell to “normal” consumers. By “normal” I mean people who were not actually makers, people not particularly familiar with the operation of technical equipment.

Those folks quickly realized the 3D printing equipment of the day was well beyond their means, in terms of reliable operations, as the equipment typically failed frequently and required technical adjustments, repairs and maintenance. Another major problem encountered was the lack of access to suitable 3D models. While there are plenty of 3D models available to download, perhaps numbered today in the millions, the question of whether any of them were desired is a hard one to answer. Even if a suitable 3D model was available, there were virtually no easy ways to guarantee finding it by normal consumers.

And certainly consumers could not be expected to learn complex and expensive 3D design software to develop their own 3D models.

Oh, and I must mention the price of the equipment at the time was ranging around USD$1,000 and up, further dampening interest in consumer 3D printing.

As a result most, if not all, of the major 3D printer manufacturers previously focused on consumer markets have either shifted their focus to professional markets or evaporated entirely.

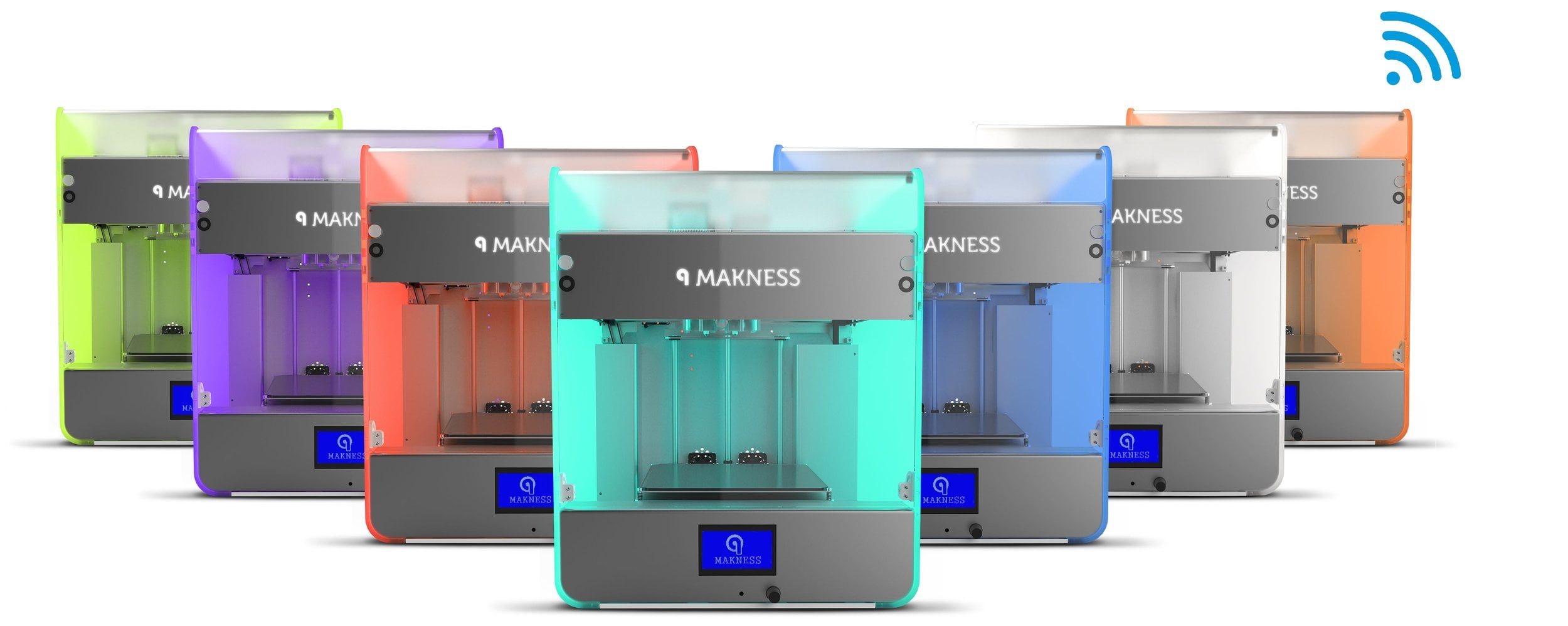

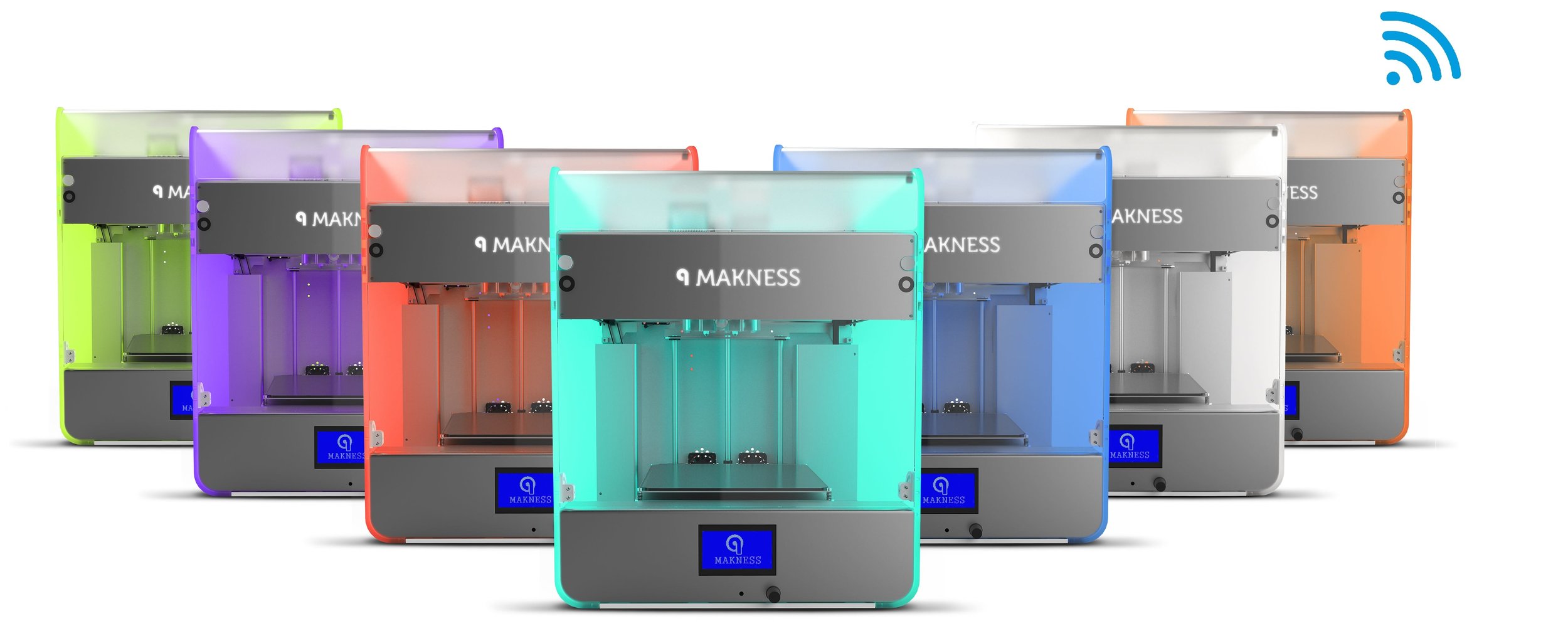

But now Spanish company Makness is attempting to enter this market again, developing their MK-1D 3D printer. But what exactly are they doing that’s different from previous attempts at this market? Let’s take a look.

The price of the machine is less than what one would have seen in the previous consumer push, currently at €649 (USD$690). That’s good, but perhaps still a bit high, considering that it is now possible to purchase competent 3D printers, albeit for DIYers, at less than USD$200.

The machine has a 200 x 200 x 200mm build volume, heated print surface and can apparently print 0.06mm layers. There’s a magnetically controlled door and an unusual internal cooling system.

Makness has developed a completely automated operations process. There appears to be zero calibrations required, and commencing a 3D print job is as simple as selecting a 3D model and pushing start. The printer seems to even lock out the operator until the cool down process is complete, simplifying release of the print from the bed.

There is one aspect of operations that cannot be totally automated, and that’s the installation of print materials. Makness has conceived the concept of what they call “capsules”, which I might call “small filament spools”, which are easily installed by dropping them into a holder on the extruder. The MK1-D loads the filament from there automatically.

The MK1-D includes two extruders (dual nozzle), permitting the use of two colors in a print. While this is an advanced function, it seems they’ve overcome the problem of how to create dual-color 3D models, a complex process to be done by proper 3D designers.

How have they overcome this? The MK1-D attaches by network to the company’s repository of 3D models, all of which have been tested and tuned on the equipment. The machine receives the correct settings to ensure a successful print.

It appears that Makness’ approach to consumer 3D printing is to control every possible aspect of the process, thus relieving the operator of the need for skills they probably don’t have.

This could work, until it doesn’t. I do have some concerns about this approach.

First, the dual nozzle arrangement, while useful for clients, might prove problematic. Those who have used dual nozzle machines tend to find reliability problems because the second nozzle can get caught up in misprinted plastic, ruining the print. There’s also the matter of maintaining calibration between the two nozzles: I’m not sure how Makness does that.

Second, the “capsules”, while easy to use, are likely expensive per weight, as compared to other generic filaments one can purchase. Their chemistry, geometry and installation process more or less ensures you must purchase them from Makness, or risk print failures. Also their “open to the air” appearance is a bit concerning as PLA plastic tends to degrade over time if left open.

Finally, the idea of limiting 3D models to a single library is quite restrictive. I understand they need to do this to ensure the success rate of prints and control the flow, but will consumers accept such a limitation? We already know that this was a problem when earlier consumer product attempts were made, so what’s changed since then?

But for some curious consumers, this machine might be quite suitable as it does appear to offer very simplified operations.

However, I must provide a caution as I always do when referring to crowdfunded projects: do not invest in this product without carefully examining the company and its products as best you can. Be prepared to lose your money should the company run into difficulties. I think I should make a checklist for readers to use in such situations.

Via Kickstarter and Makness