Researchers in Singapore have developed new elastomeric materials that could be used in 3D printing applications.

Flexy materials have been around for a while in the 3D printing world, and have been used in a variety of ways, including “coating” handles with grippy surfaces, integrating flexible hinges into a 3D model or even producing bouncy tires for wheeled applications.

Some of these flexible materials can stretch a bit, but most simply flex. You’ll find a selection of flexible filaments available, as well as some photocurable resins used in other 3D printing processes.

Like other materials, it’s advantageous to 3D print flexible and stretchy objects because you can achieve shapes that are not possible to produce using standard making approaches.

Now the researchers have apparently developed a far more powerful elastomer that could be used in photocuring-process 3D printers. The abstract from their paper explains:

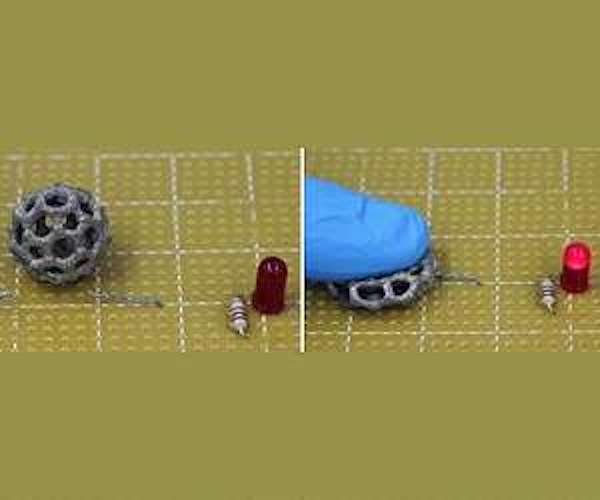

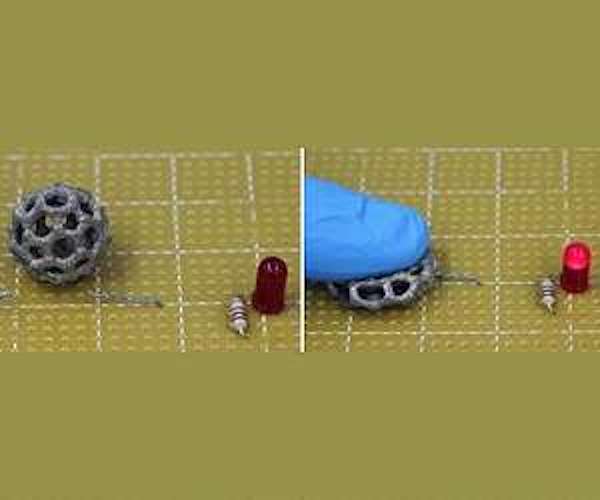

Stretchable UV curable (SUV) elastomers can be stretched by up to 1100% and are suitable for digital light processing (DLP) based 3D printing technology. DLP printing of these SUV elastomers enables the direct creation of highly deformable complex 3D hollow structures such as balloons, soft actuators, grippers, and Bucky ball electronical switches.

According to a report on SpaceDaily, the new material can be stretched:

…More than five times the elongation at break of any commercially available elastomer that is suitable for UV curing based 3D printing techniques.

What does all this mean? I suspect it simply extends the envelope of 3D printing possibilities. The current capability of 3D printing is essentially proportional the available engineering properties of the available materials. This material definitely adds new capabilities.

What will designers make with this? One can only imagine.

Via SpaceDaily