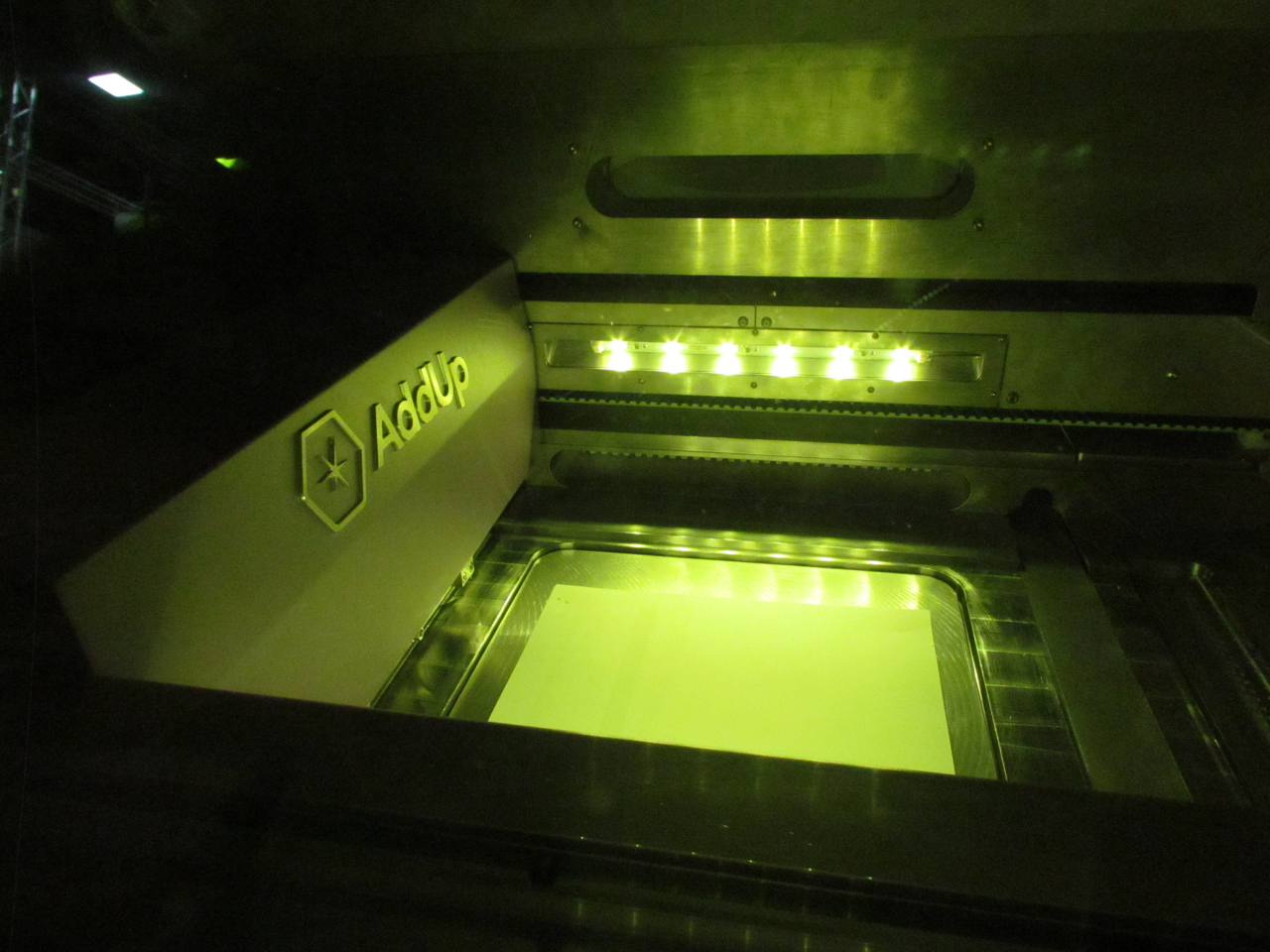

We’re looking at AddUp’s FormUp 350, a 3D metal printer that’s attracting some attention.

AddUp is a new company that is a joint venture between Michelin and French industrial engineering giant Fives Group, who are well known for building a wide variety of industrial machinery.

The FormUp 350, their flagship printer, ass a standard metal powder-bed design with a powerful laser to fuse layers. The machine is highly flexible, in that it can use “open materials” supplied by the customer.

Now you might be wondering what’s so special about this machine. I would say that it isn’t the machine itself, but rather its marketing potential.

One of AddUp’s backers, Michelin, is deep into 3D printing and in fact apparently has 30 machines making something around one million 3D printed parts per year.

Now they have a partner company that makes 3D metal printers. What do you think will happen?

It seems to me that Michelin will provide a kind of “instant market” for AddUp’s €730K (USD$775K), consuming a healthy chunk of their initial production. This will make AddUp a big contender in the 3D metal printer market almost immediately.

So far, we’re told they’ve sold three machines and are building more, with staff going from currently 50 people to 100 by the fall of 2017.

The machine has a number of options that can be applied to customer configurations, such as the powder unit shown here. But what’s really interesting is their transportable factory concept.

Here we see a small 3D model of the concept. It’s composed of a series of environmentally controlled rooms that can be assembled in arbitrary configurations to meet the customer’s requirements. You might, for example, have a couple for printers, but many for extensive post-processing. Or vice versa; it depends on the client’s needs. You can even put them outside to create a kind of portable factory.

In the competitive 3D metal printing market, AddUp is one of the contenders.

Via AddUp