This week I managed to get a closer look at the new 3D printing system from startup Rize.

I’ve written about this currently unreleased machine previously, but there’s no substitution for looking at the machine in person. I’ve come to realize that the technological approach taken by this company could be quite a breakthrough in the world of 3D printing.

Let’s do a quick refresher on how it works first.

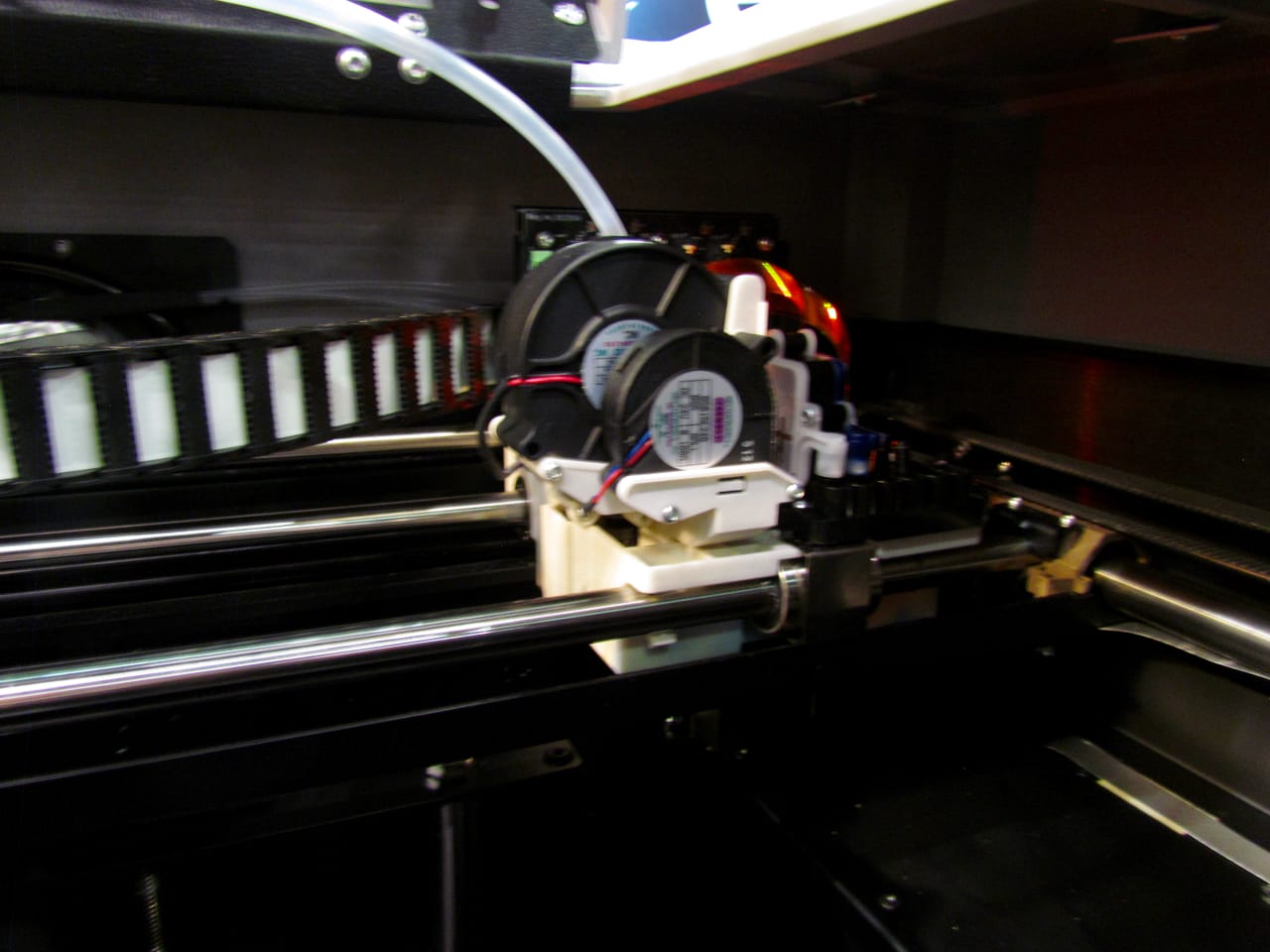

The Rize system is composed of a single plastic filament extruder, not unlike many other desktop 3D printer units. They use their own proprietary filament, but there’s a reason for that, which I shall explain momentarily.

So far this machine sounds like any other, but the next feature is what makes it different. In addition to the extruder, the Rize system also includes what they call a “print head”. This print head is in fact very similar to what you might see in an ink jet printer: a device with a great many tiny nozzles capable of depositing fine drops of liquid selectively.

Ok, so far, so good. Now here’s how the system works in its initial configuration: 3D printing occurs in the usual manner, but support structures must be built from the same material as the model, obviously, because there is no other material available in the single-nozzle Rize system.

For those concerned about the pricing of proprietary materials, we’re told the price should be about USD$99 per kg, about double that of generic materials, but far less than other proprietary filament materials from other vendors.

Normally, such breakaway support structures attempt to maintain minimal contact points with the main body of the print in order to eliminate the rough surfaces where the touch takes place. Sometimes this minimal contact is a compromise between providing adequate support and minimizing surface damage. Sometimes you end up carving off rogue breakaway supports that won’t easily release.

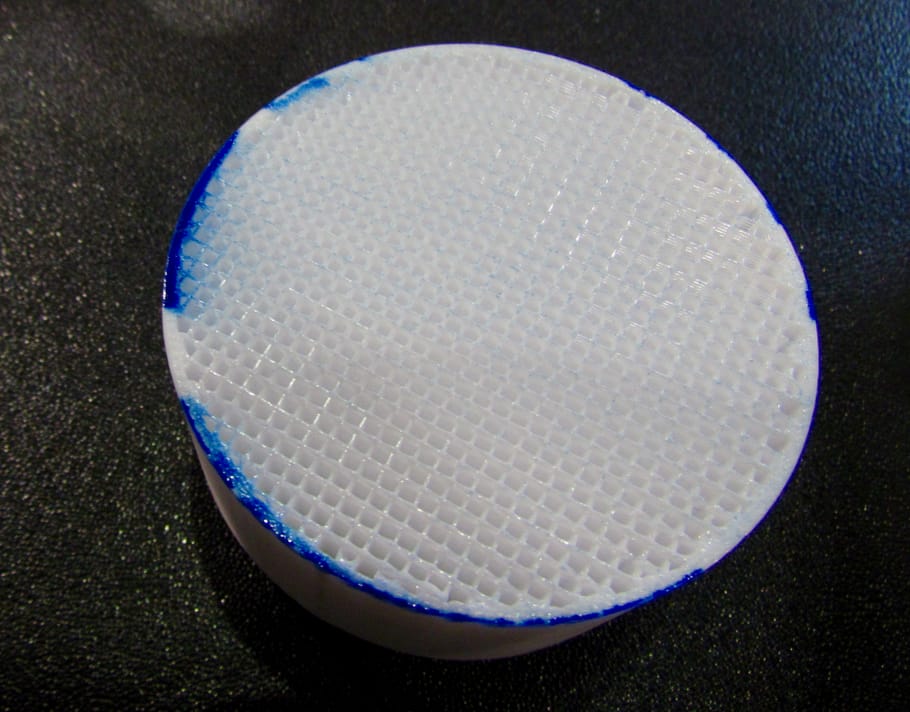

That doesn’t happen on the Rize system because of their fascinating print head innovation: at the point of contact, the print head sprays the contact area with a specialized solution, which they call “Release One”. This substance permits the support and model sections to touch for support purposes, but prevents them from fusing together!

This creates a situation where the support contact points need not be minimized, as they just fall off after printing and do not create rough surfaces on the model.

This is incredibly useful, but there are a few situations where this won’t work well, in which the support material is somehow embedded in the model and can’t easily be removed. For those you may have to adapt your model or reorient it to minimize the effect.

If that’s not sufficiently interesting, keep reading. There is MUCH more to this.

The print head in the Rize unit actually includes TWO ink jet sources. One of them, as explained above, would normally contain the Release One liquid. The other can contain ink.

This means that the Rize system can apply ink to surfaces as the print takes place. Here you can see examples of how this is done.

Logos can be emblazoned on a print. Images can be printed in grey scale. You imagination must be percolating at this point.

But it gets better.

The initial system has one print head, as described. However, the Rize design actually includes space for not one, but TWO more print heads, providing the ability to engage SIX liquid depositions simultaneously.

Now what would we want to use them for? How about this: CMYK. (That’s Cyan, Magenta, Yellow and Black, for you non-print tech readers, the basic color set that can mix to form ANY known color.)

Yes, you could actually create full RGB color with this system! If configured in this way, it’s possible this system could print full color textured plastic objects.

And there’s even more. The release material, plus CYMK is five liquids to dispense. On the fully tricked-out Rize system, there are six. One is empty.

It appears that it is Rize’s intention to use this empty slot eventually to include another specialized liquid that can smooth the printed surfaces. A type of “polisher”, I’d say. The chemical approach to smoothing prints has been done a few times in the past, with acetone vapor applied to ABS prints, tetrahydrofuran for smoothing PLA and similar. However, all of them are applied to the print after it’s completed.

Rize wants to do it WHILE THE PRINTING TAKES PLACE.

Thus, in the end it seems that Rize should be able to 3D print strong, smooth plastic objects in full color, right out of the machine. No one else can do that.

Rize formally released this machine at Solidworks World last week, at least in “single color” mode. As for the full color and perhaps even automated smoothing, that may even happen as well by the end of 2017.

Via Rize