Stratasys is using a well-known manufacturing methodology to guide the development of their new equipment.

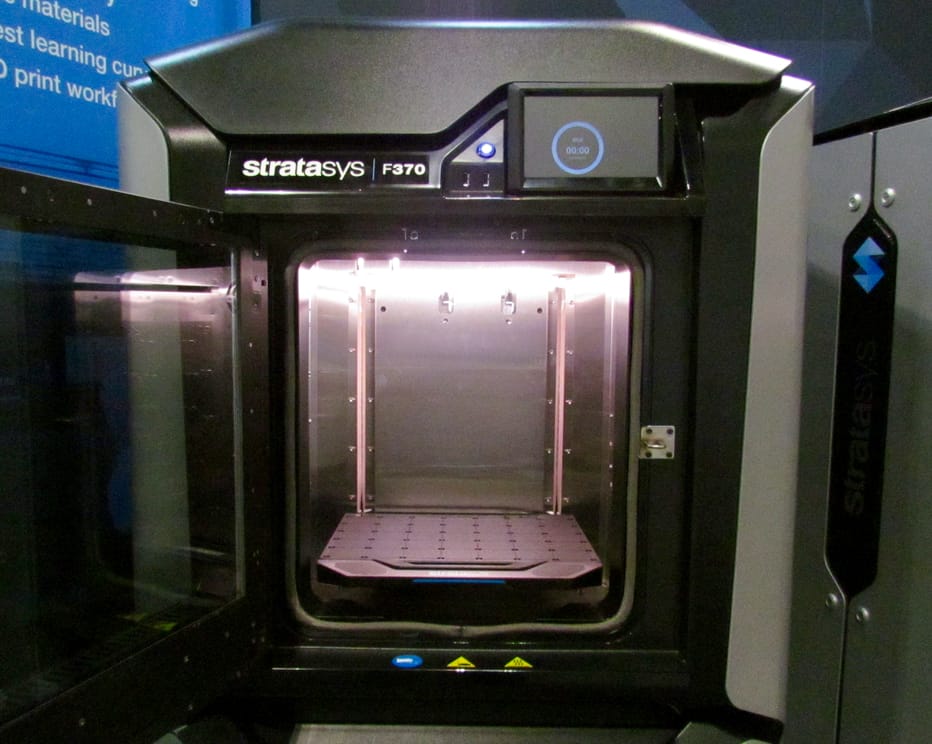

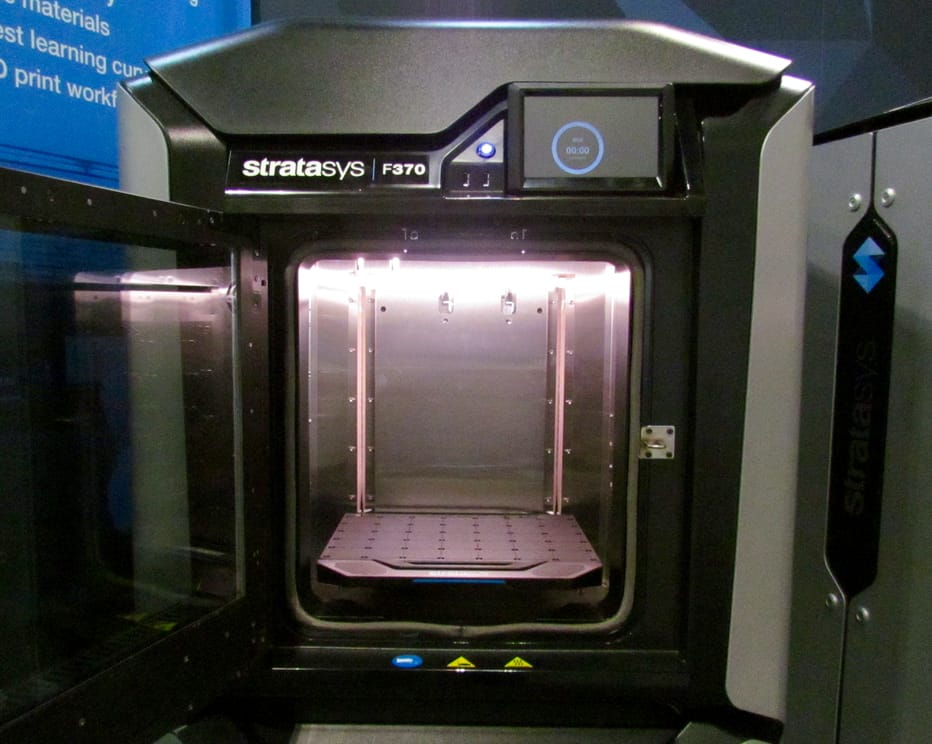

I was pretty impressed with Stratasys’ new F123 series as it included a number of visibly improved features, but what was also quite interesting was the “invisible” features.

By “invisible” I mean they aren’t things you might find on a typical specifications sheet. They are implications that one would find when using the machine, rather than hardware or software features directly.

Stratasys explained that their new equipment offered a number of productivity improvements. Some of them are easy to identify, such as their new easy-load filament system, shown below.

I agree with their strategy of trying to make life easier with operating their equipment, as sometimes 3D printer manufacturers overly focus on the technical specifications and forget that people have to actually use the machines for productive purposes. Their focus on usage is something all 3D printer manufacturers should do a lot more of.

But what I didn’t realize is that Stratasys is using a very specific manufacturing methodology to achieve this. In a post this week they revealed this:

Before embarking on a 3D printing investment, it’s important to understand the difference between an “over-the-counter” 3D printer and a professional rapid prototyping solution. To do this, business decision makers should compare the “Overall Solution Effectiveness” of these two classes of systems.

and

Overall Solution Effectiveness is a best-practice methodology from the manufacturing world; it was coined by Seiichi Nakajima in the 1960s. At its simplest, Overall Solution Effectiveness determines how much of your manufacturing time is truly productive. For the design world, we can adopt similar criteria to determine how efficient and effective a rapid prototyping and 3D printing set-up is.

Essentially, this methodology attempt to ensure prints are of the best quality, produced at the fastest speed and without interruptions.

These are the qualities that should be highly sought after by the professional designer market Stratasys (and many others) are addressing.

By understanding this methodology, Stratasys can gradually engineer their equipment to optimize these very things when someone operates the machines. This methodology would be used in the design of Stratasys equipment to make decisions on features and prioritize design options.

This is a very powerful approach that, over time, should make Stratasys equipment highly desirable.

Meanwhile, I have seen other vendors try to address “ease of use” and “productivity”, but none in such a formalized – and proven – way.

Perhaps other 3D printer manufacturers should do something similar.

Via Stratasys