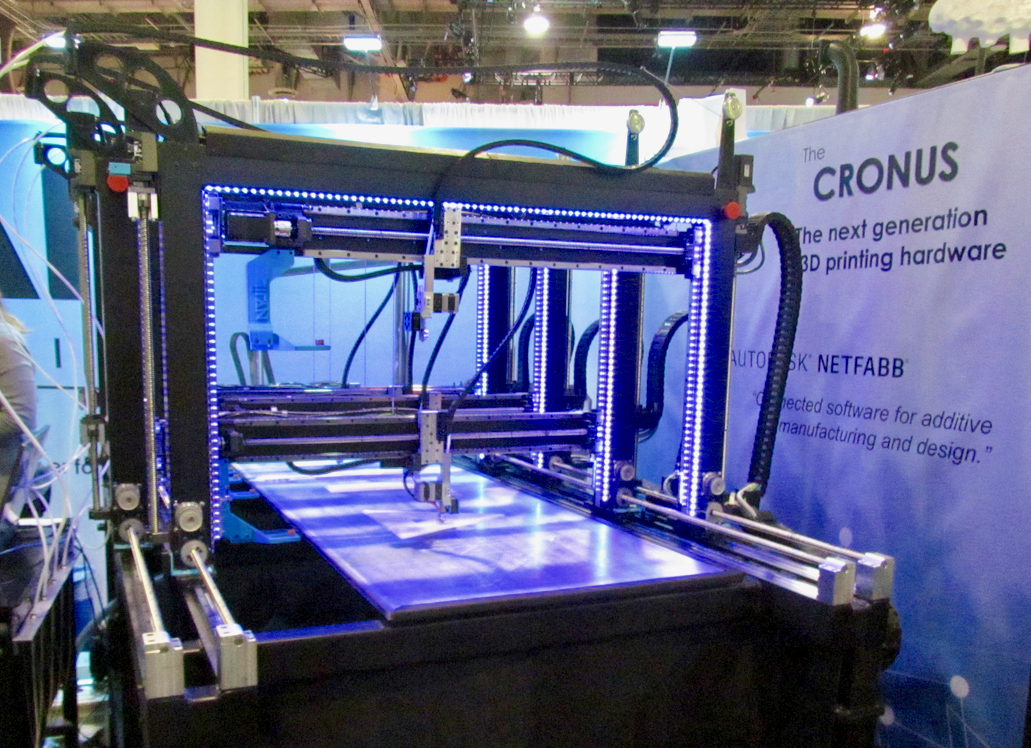

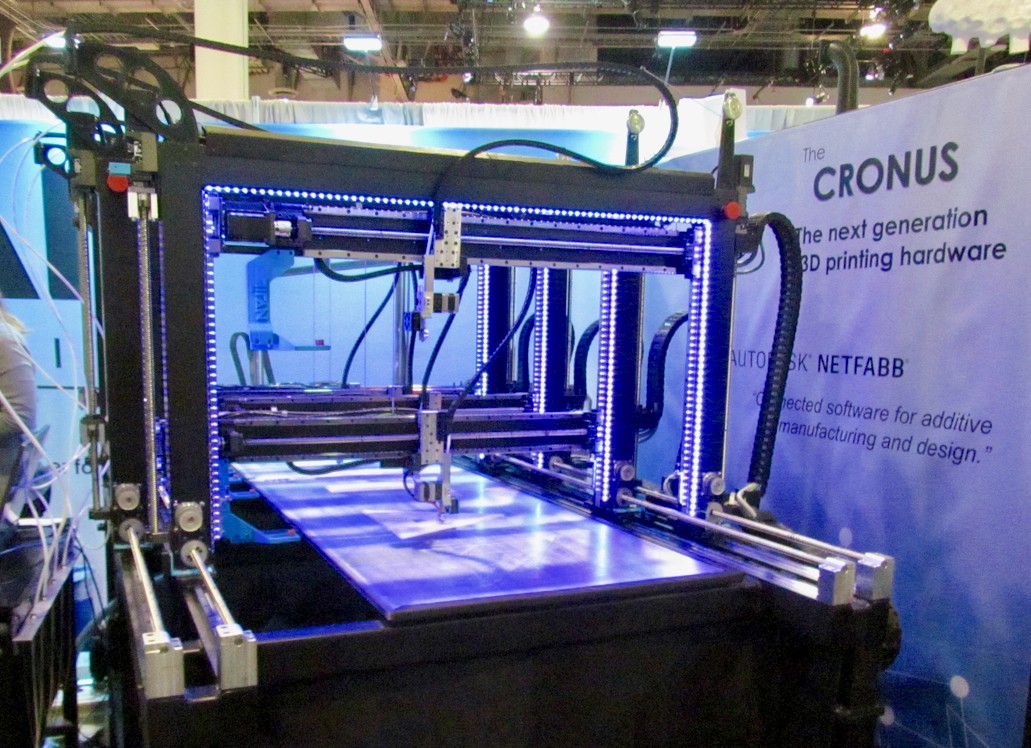

Titan Robotics has constructed one of the most unusual 3D printers I’ve yet seen.

The new machine is based on the Autodesk Escher concept, and I believe this could be the very first commercial implementation of the system.

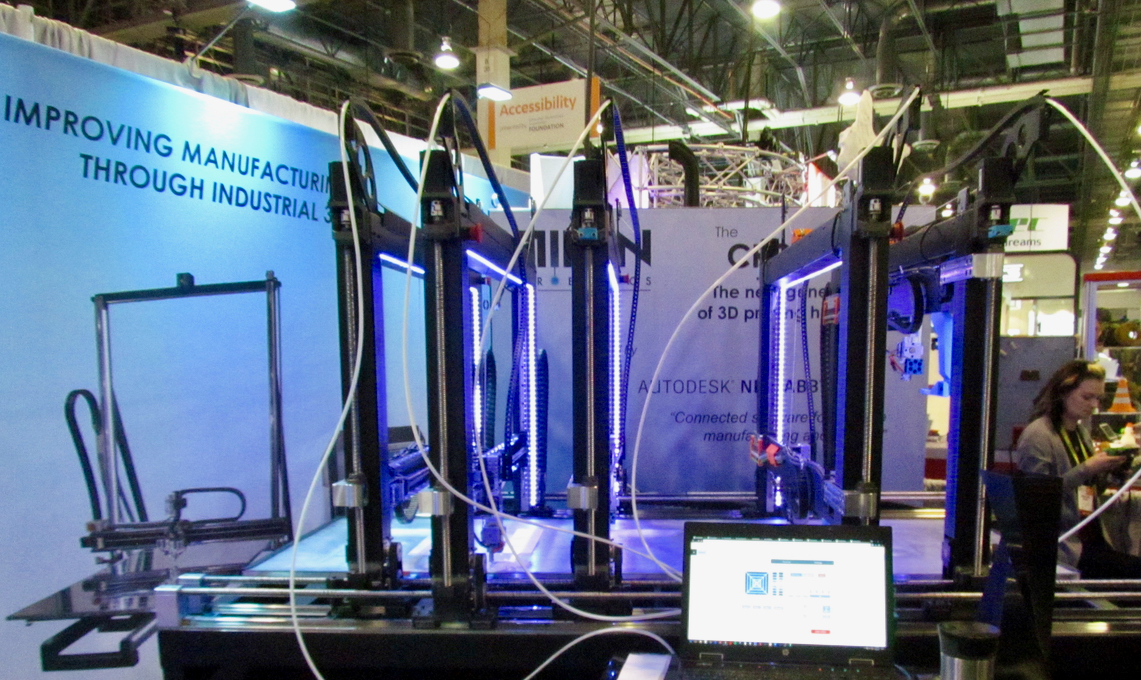

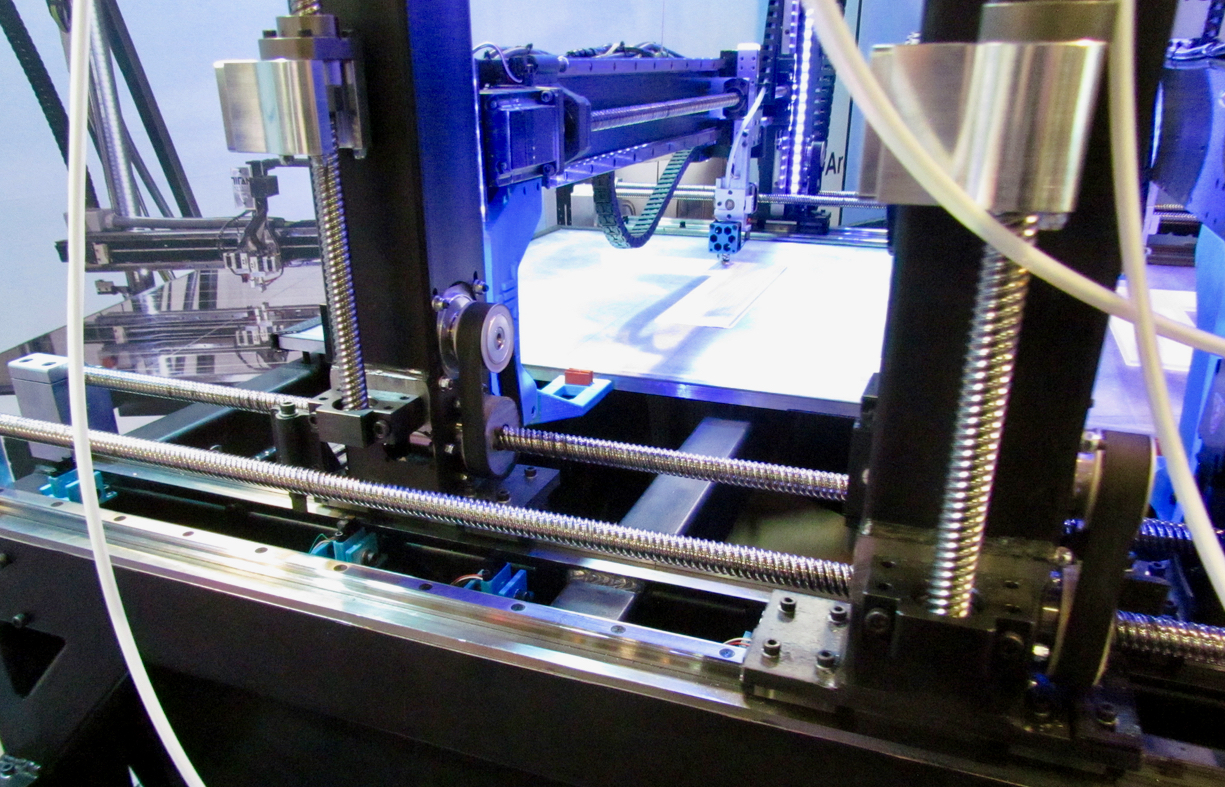

The first thing to note on this large machine is that it includes multiple motion systems. This enables you to print multiple objects independently; that is to say, the extruders do not necessarily move synchronously and you can print multiple DIFFERENT objects at the same time. There is also the possibility of 3D printing a single large object and have the multiple extruders all work on different parts at once. It’s a flexible system that can produce a lot of printing in a short time.

The up-to five print heads are fascinating to watch as they’ve independently across the 1,828 x 762 x 508 build volume.

As you can tell, this machine is open to the air and thus is capable of printing only PLA and PETG plastics at this time. However, we were told there is an enclosed version as well. That enclosure enables printing of additional material types, such as ABS, PC, PBT, HIPs and several others, although I suspect very large ABS prints could be problematic at such a size.

I’d tell you more specifications, but it wouldn’t be reasonable to do so, simply because all of Titan Robotic’s products are essentially custom built. While there is a default build volume, for example, they can easily adjust that when the machine is built for the customer. The number of gantries is variable. The nature of the extruders could change, etc.

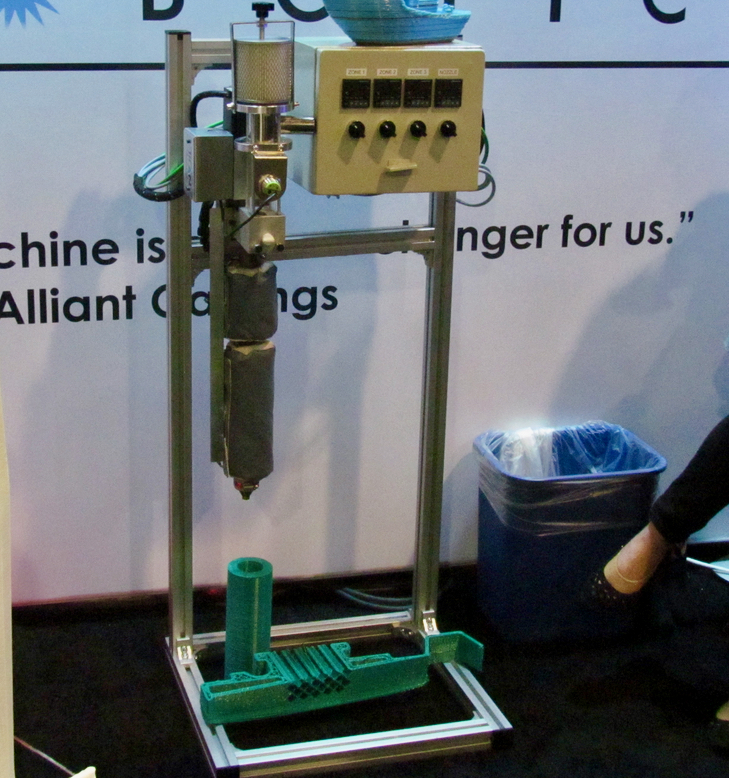

And that’s another important option on this machine: while the device shown uses standard plastic filament as the material, it is also possible to use a pellet system being developed by Titan Robotics, shown here. A pellet system could enable much more rapid – and less expensive – 3D printing operations, which is particularly important when producing large prints on a machine like the Cronus.

The company has also been experimenting with a material we haven’t seen before: PPS or polyphenylene sulfide, sometimes referred to as “Ryton”. This unusual material offers thermal resistance up to 260C, high dimensional stability, flame retardancy and strong chemical resistance. We hand examined a test print of this substance and found it to be ridiculously strong.

The Cronus, like all Titan Robotics equipment, is made to the highest standards of machinery. The device should be highly reliable and produce excellent output, even at this size.

I spoke with Titan Robotics founder Clay Guillory to find out more about this machine.

Guillory explained that it was quite a project to produce. Although he said the design was completed in only 5-6 hours, it took over a month to actually build the Cronus, as it is called. Apparently the machine required over two MILES of wire!

So far they have made two units, and expect to make more as customers demand. Guillory expects to have formal public availability sometime in February, not far away from today. Pricing is variable and depends on a variety of optional features that may or may not be installed. However, the price is expected to be “in the low to mid six figures”.

Looking for a reliable large machine? Consider Titan Robotics.

Via Titan Robotics