Today I’m looking at something called, “The Filament Roller” that just launched on Kickstarter.

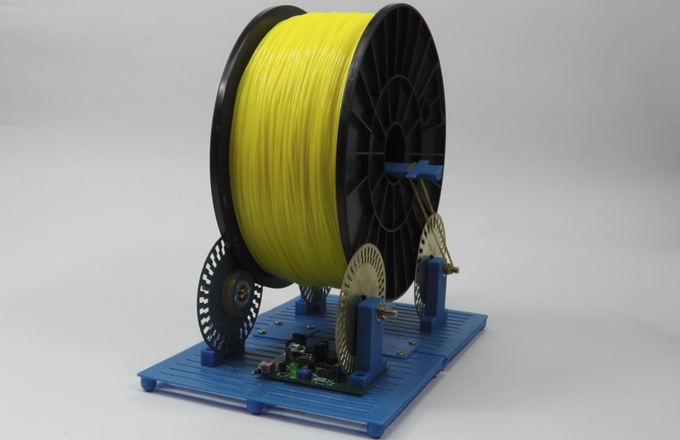

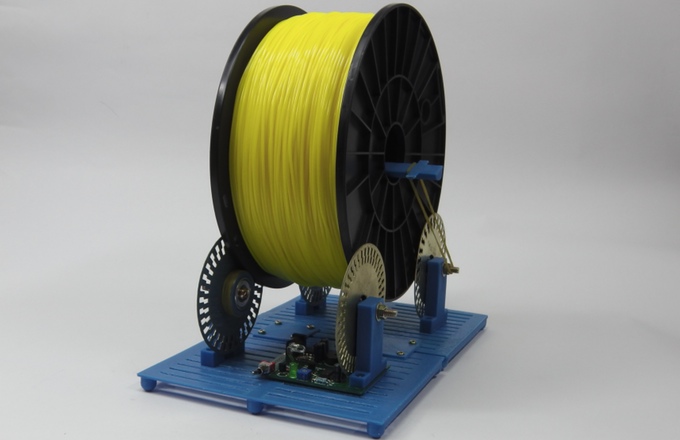

The product is a kit for constructing a rather flexible filament monitoring system that could be attached to many desktop 3D printers.

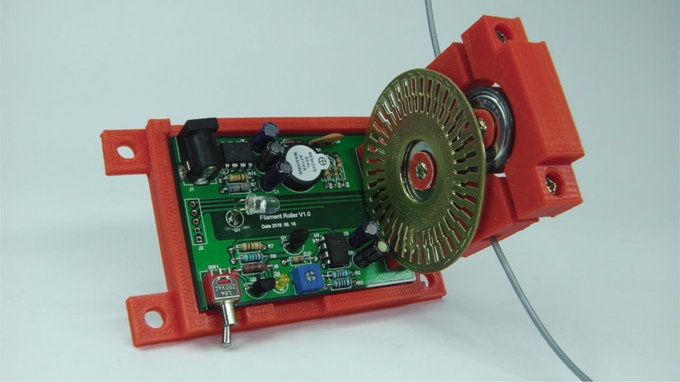

The Filament Roller is a straightforward system in which the filament path traverses the detector, whose key component is a perforated wheel that rotates in front of an infrared sensor as the filament passes. The perforations signal that filament is successfully moving. In the course of a print operation, the signals will be intermittent as the consumption of filament will vary as the print proceeds through the model’s geometry layer by layer.

Detection triggers occur when the filament progress signals from the wheel are not seen for longer than a timeout period. The timeout period is set by you as a value between 3 and 48 seconds. Thus the Filament Roller is able to handle both forward and reverse (retraction) movements of the filament.

When a timeout event is detected, the Filament Roller will provide a signal that can be accepted by external equipment such as an Octoprint set top box, and the print operation can be paused for investigation and resolution. The Filament Roller can also blast a 100dB buzzer for a human interruption.

To use the device, you print the freely provided plastic components, plug it all in and set the timeout value. It’s also possible to design and print a specialized plastic mount that better matches your particular spooling configuration, too.

You might think something like this is a frivolous and unnecessary accessory to a desktop 3D printing setup, but I can tell you that there are countless failure scenarios directly related to filament feeding. I’ve experienced many of them and likely you have too.

The “out of filament” condition is certainly one of them, but there are many instances where the spool simply doesn’t feed due to friction, filament knotting, poor grip on filament of inconsistent diameter and many more situations. Each of these will literally kill your print, waste a quantity of expensive plastic filament and most importantly burn your valuable time.

It’s because 3D printer manufacturers generally ignore this aspect of print operation and leave it to others to solve, particularly the buyer of the machine. Typical desktop 3D printers simply offer a post on which to hang your filament spool, and very often I’ve found them inadequate in terms of positioning, access, filament bend, smooth rotation and fit. By “Fit”, I mean situations where you purchase third party filament spools that don’t fit on the manufacturer’s spooling post.

These problems often require 3D printer operators to “invent” their own spooling systems, like a hangar system as shown here, where filament is more easily and reliably fed into an old MakerBot Replicator.

The Filament Roller should fix many of these issues.

If I have one beef with this system, it’s that it’s a kit that might require some work to install. It’s not much, but enough to scare away some 3D printer operators. The device is also not compatible with all 3D printers, but certainly will work with a great many that are based on RepRap designs – and use a set top box like OctoPrint.

The product is available for order on Kickstarter now, where you can pick up a single spooling system for only USD$44, but for those with dual or multi-head 3D printers, you might consider buying a double pack for USD$78 or the five pack for USD$184.

[UPDATE] Chris Robertson, the fellow behind the Filament Roller, contacted us with a clarification regarding the compatibllity of the unit:

The Filament Roller is compatible as an endstop sensor with Marlin firmware v. 1.1.x OR OctoPrint with any printer which is compatible with OctoPrint.

Via Kickstarter