The curiously-named Something 3D company has figured out a way to actually 3D print color objects with a filament extruder.

The three-year old Israeli company has seemingly found a way to perform multi-color, RGB-style 3D printing using a filament-powered extrusion system.

3D printing in color has been a goal of many for years, but has almost always had major challenges. The concept is simple: feed filaments of the four primary colors into a single extruder and adjust the feeds and speeds to allow the plastics to mix and produce the desired color, which is extruded through the nozzle.

Sounds easy, doesn’t it? Except there’s a huge problem.

The “mixing” happens inside the nozzle where there is a “lag” between the original color. 3D printer operators may recall the time it takes to swap a color filament: you typically run the extruder for several seconds to watch the “old” color slowly change into the fresh “new” color.

The solution for some full color extrusion machines is to simply move the extruder off to the side and “purge” out the old color and then resume printing with the new color. Now imagine doing that kind of color swap for every portion of a brilliantly textured 3D model! You would be purging almost constantly, wasting a massive proportion of materials as incorrectly mixed colors.

Some machines try to leverage this effect by touting a gradual layered color change. But while that is mildly interesting, it is hardly useful for printing anything specific: the color change becomes visible over multiple layers of the print!

But now Something 3D has come up with a way that just might work.

[Aside: I asked how they picked their company name, and found they had to “name it something.”]

Does it work? Look at these prints. Note – these were apparently produced directly on the Something 3D equipment using plastic filaments only; no post print painting was undertaken. They look exactly like this when printing completes.

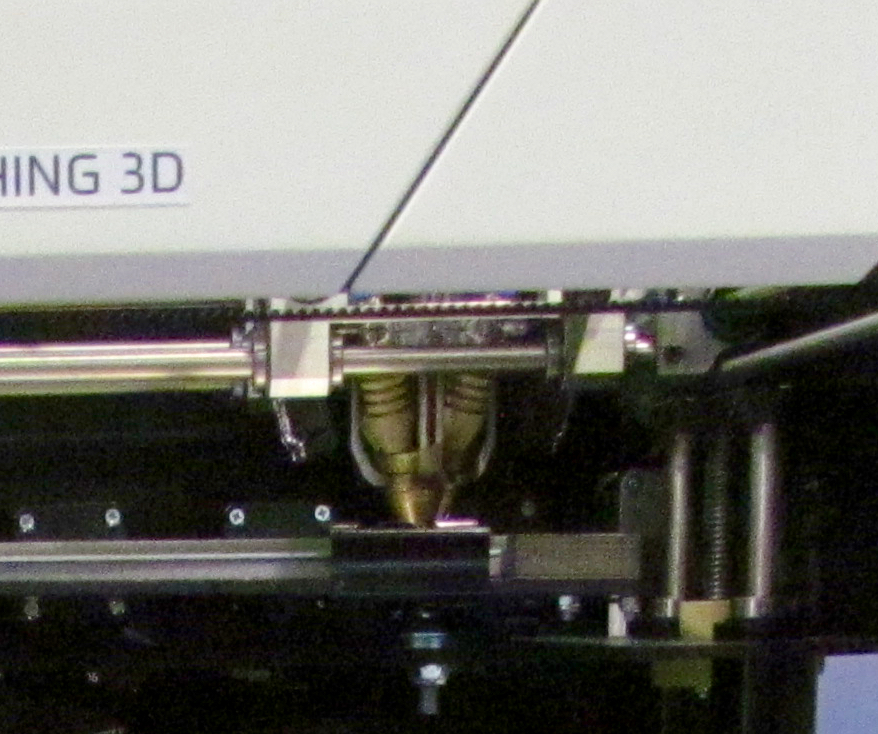

It seems that Something 3D has figured out a way to very rapidly switch colors without incurring massive purging. How do they do so? I was told they have an ingenious nozzle design, combined with some tricky software controls, which no doubt perform some delicate mechanical maneuvers that work in conjunction with the nozzle flow. They explained they have “special GCODE to enable color textures”.

This enables them to control color textures on a voxel level! There’s very little color slop from one voxel to adjacent ones.

The example prints they showed us were simple shapes with a JPEG image applied to the surface. It’s a very simple texture application, but one that can clearly demonstrate the power of this technique. Evidently the system is capable of 3D printing “thousands of colors” and that Something 3D “can raise this”.

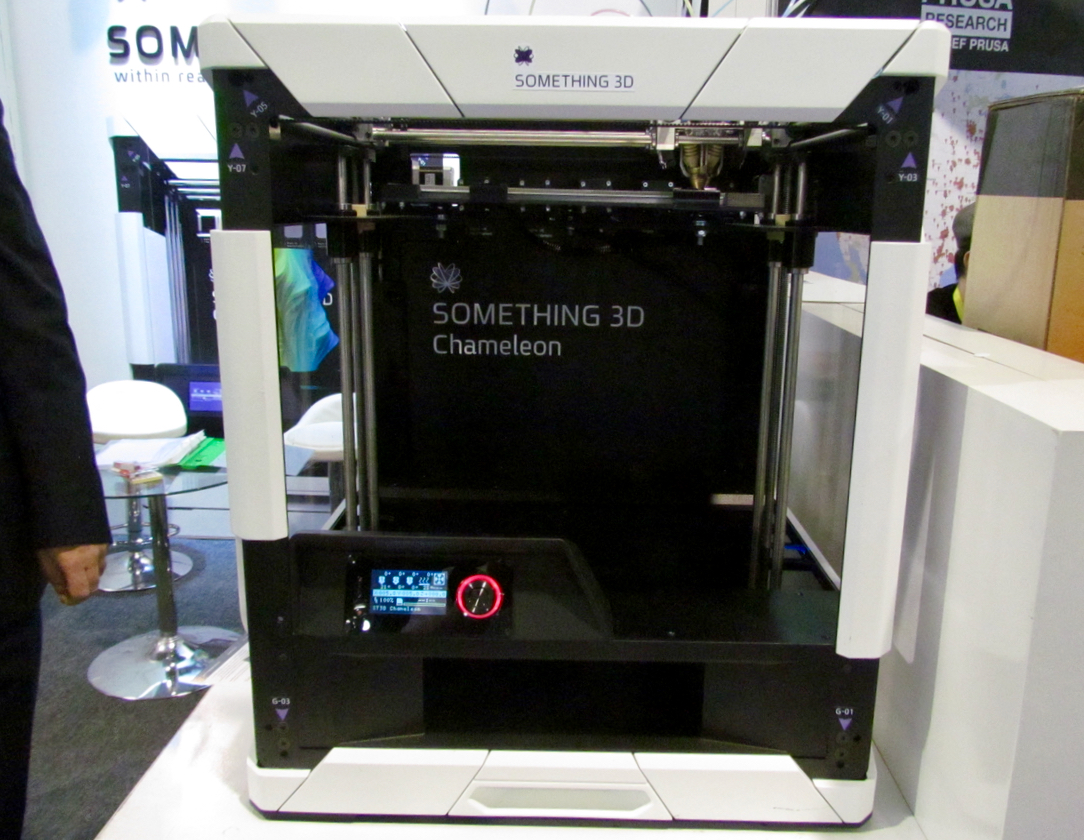

The prototype machine that performs all this is the “Chameleon”, a very apt name.

For materials if printing in full color, the Chameleon requires five colors of filament: white, magenta, cyan, yellow and black. And that’s exactly what you’ll find in this “WCYMK” cartridge.

Now at this point I must point out that this particular cartridge is a huge milestone for the 3D printing industry. As far as I can tell, this is the very first time “full color” materials have been seen in a single cartridge, a long held dream that positions a 3D printer in the same mode as a color 2D printer might be seen.

One critically important point about this technology is that it is not limited to “colors”. Imagine if you substituted different filament materials instead of WCMYK? You might have a flexible filament, able to introduce fine flex components to your print. Or perhaps a conductive filament could be used to lay down simple embedded electric circuits. A carbon fiber or nylon filament could provide strength in required areas. You get the idea.

Can you buy a Chameleon? Well, not really. The company does sell “mono” versions of the device for USD$2,500 and USD$5,000 for a larger version.

No, instead the company really exhibited the device as a demonstration only. They’re actually wishing to become a technology supplier to others who would integrate the tech into their machines. Currently they are seeking partners, so if you happen to own a 3D printer company, you might want to give them a shout.

And it’s not limited to hardware partners; imagine a Photoshop Plugin that takes a colored 3D model and converts it Something 3D GCODE for printing, for example.

Something 3D is onto something big.

Via Something 3D