Yes, it’s the beginning of a new year and I had some thoughts on what might happen.

These are not predictions, but just thoughts based on trends I’ve observed over the past year and what might happen in the future. In no particular order:

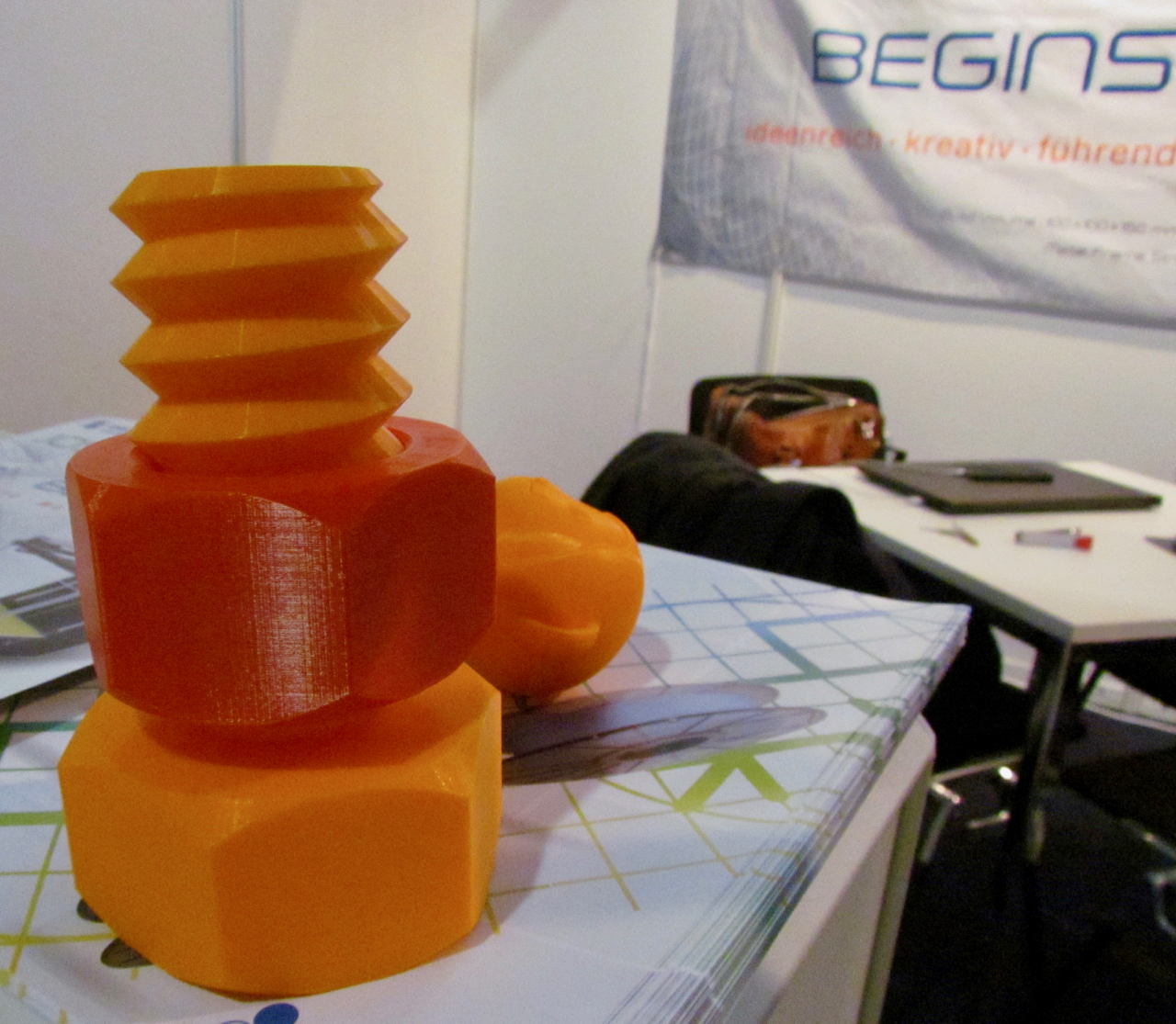

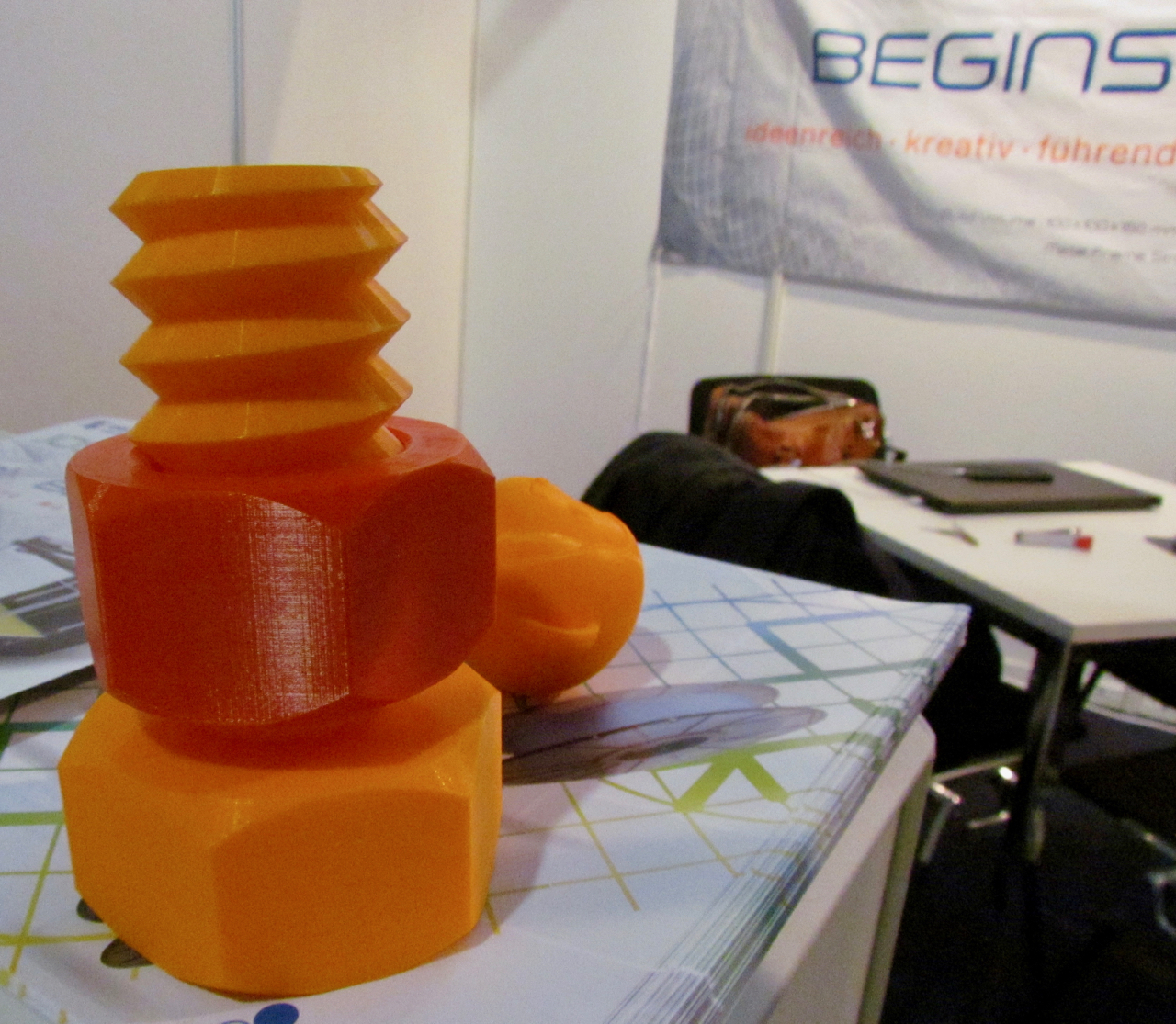

Irrelevant crowdfunded desktop 3D printers disappear: 2016 was the year when it became very clear that basic 3D printers launched in someone’s garage are no longer relevant. The functions and capabilities of such machines have long been overtaken by larger, existing manufacturers who can offer the same capabilities at lower prices – and far lower risk.

Unless someone invents a completely, entirely new 3D printing process with significant advantages, they have virtually no chance of being successful in such a venture in 2017.

Shakeups at 3D Systems and Stratasys: For decades, 3D Systems and Stratasys owned the 3D printing market due to their control of patents – of which many have now expired, opening up the market to others. In 2015 and 2016 we saw the entrance of huge players to the industrial 3D printing market, such as Ricoh, HP and several others. Their size is vastly greater than 3D Systems or Stratasys and could rapidly catch up and outspend them. In addition, there have been multiple new smaller entrants equipped with unusual and powerful new technologies. Any of these could also bite strongly into existing markets.

Thus, 2017 is the year when both Stratasys and 3D Systems will make their stand against this onslaught. Will they succeed? I don’t now, but if they struggle, there could be shakeups of a fundamental nature.

Materials challenge machines: As the desktop 3D printer market shifts towards professional use, so does the use of materials. Professionals require a wider variety of materials offering more interesting engineering properties, and there are a number of new machines recently announced that cater to that type of printing. However, there are many desktop machines that were originally designed around the earlier consumer paradigm of plastics PLA and ABS “if you have to”, that may not survive the competition. In a way, the explosion of different materials will expose many current machines to challenges they cannot meet.

Incrementally improved, not revolutionary new 3D design tools: 3D printers require 3D models to operate, but not everyone knows how to design in 3D. It’s a challenging skill, not only because it requires your brain to think a bit differently and is time consuming to learn, but also because the tools are often very expensive. Will this change? I think not, as the software manufacturers have little incentive to change their valuable business models and no one else seems able to invent easy methods of 3D design that have caught on to large portions of the public.

Consolidation of materials manufacturers: In recent years there has been a small explosion of 3D print materials providers, as existing chemical and plastics manufacturers sought an additional line of business by adapting their equipment and production lines to produce 3D print materials. However, their skill level in addressing the specific needs of the 3D print community are quite varied and I believe we will see many of them drop out of the market and leave it to others that are more dedicated to the space.

Evaporation of many desktop 3D printer manufacturers: Making a desktop 3D printer became infinitely more challenging in 2016. At the higher end, many new manufacturers released very powerful machines capable of producing engineering-quality prints suitable for professional use. At the low end, larger manufacturing entities such as Kinpo Group (XYZprinting) have driven the price of machines to such low levels that it’s becoming impossible to even launch a reasonable low cost machine. As a result, expect to see a number of smaller manufacturers disappear in 2017.

And of course 2017 will hold many surprises, but I can’t say what they will be because no one has told us!