Italy-based MeccatroniCore offers a small line of impressive desktop 3D printer units suitable for professional use.

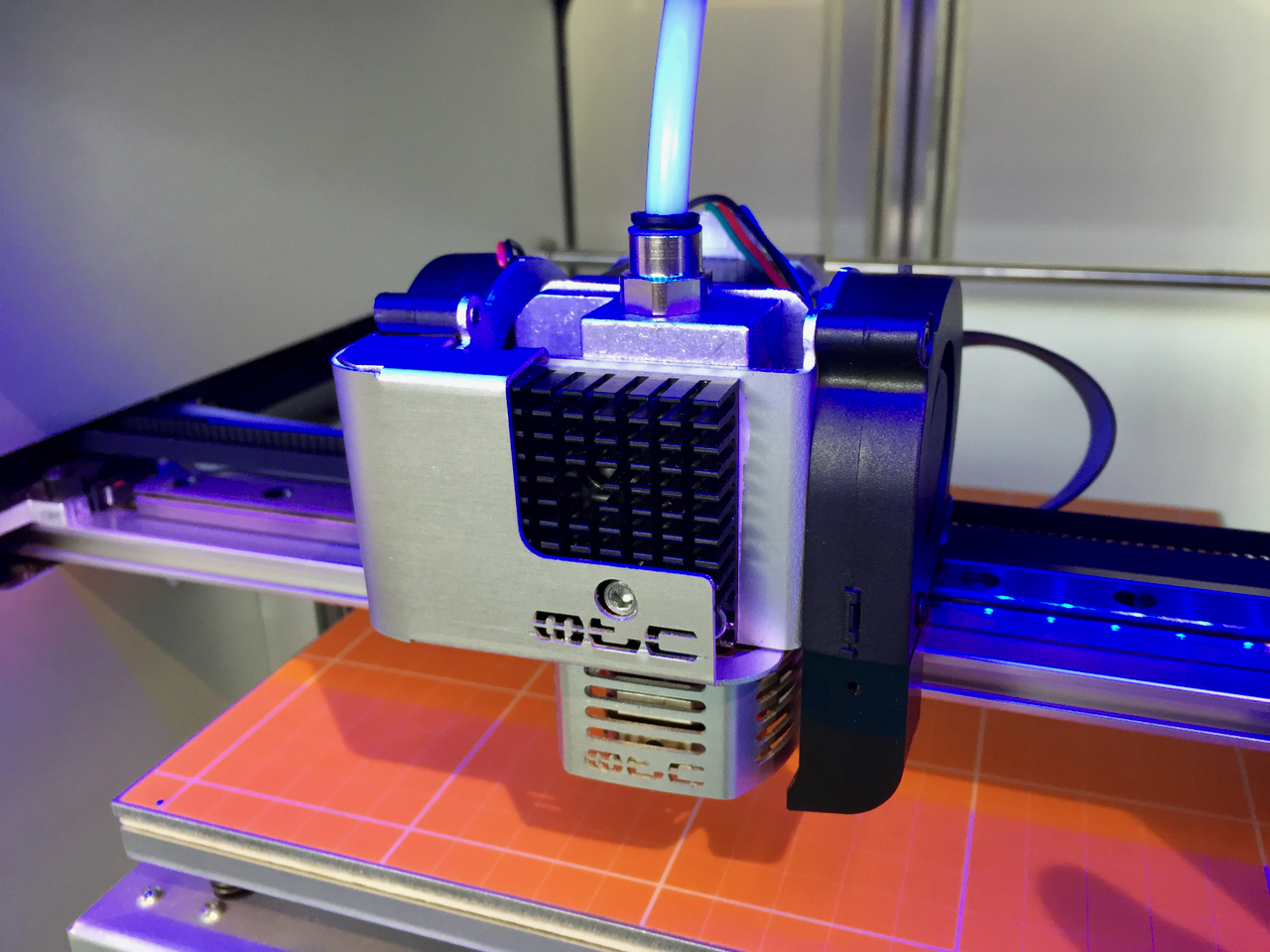

The company’s premier product is the Leonardo 300, named obviously due to the unit’s build volume: 300 x 300 x 300mm. Inside that generous build volume you will find dual extruders suitable of 3D printing a wide variety of materials, including PLA, ABS, Nylon, flexible TPU, HIPS, PVA and many others. The machines rated thinnest layer is 0.05mm, enabling very fine prints.

The Leonardo 300, seen at top, has a heated print surface and enclosed build chamber for print reliability. Steel nozzles are used instead of brass to take the punishment of composite filaments with embedded hard particles, such as metal or ceramic. The machine also includes an out-of-filament detection system.

The €7,000 (USD$7,400) system is intended for professionals requiring accurate, reliable desktop 3D printing of arbitrary engineering-grade materials.

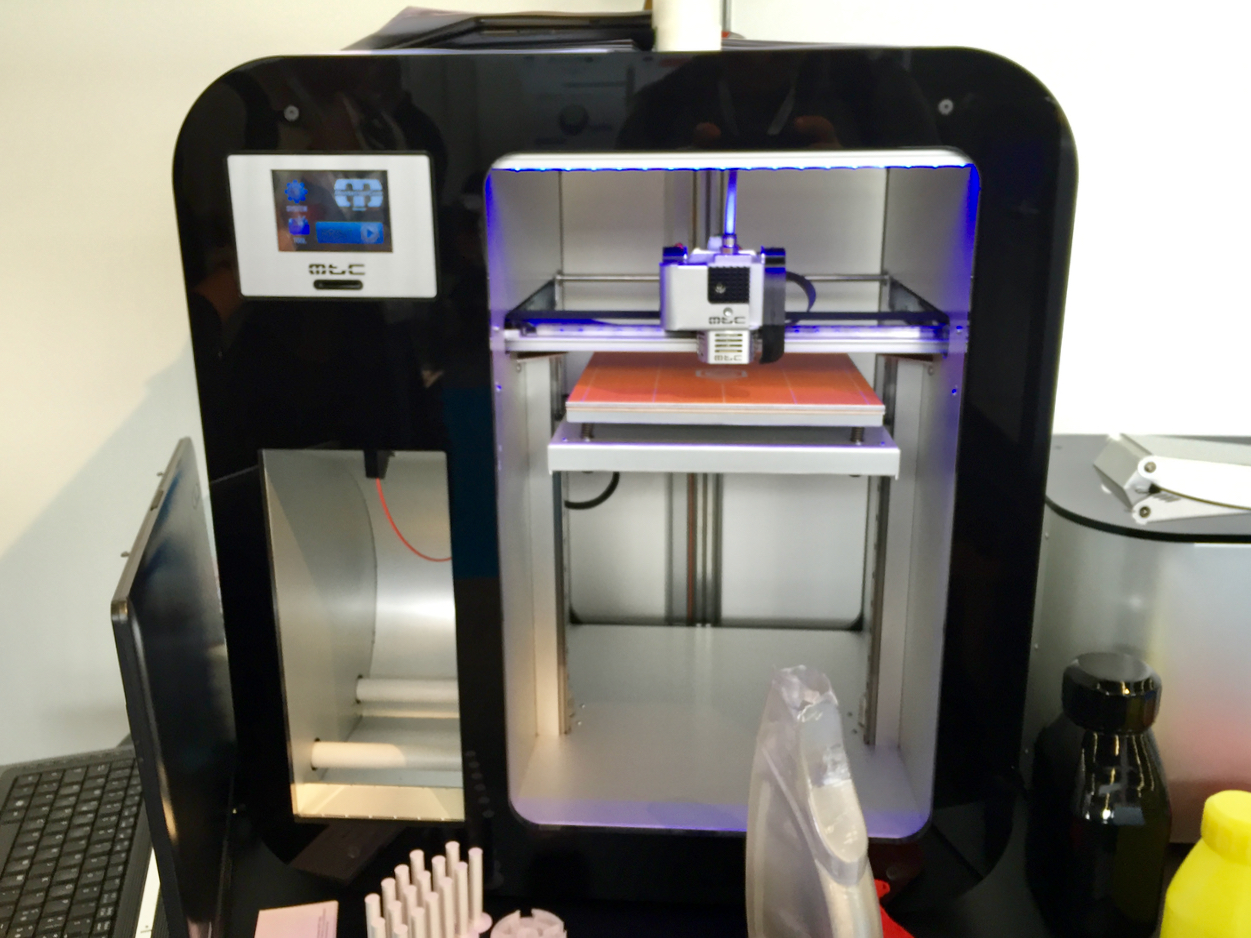

But that’s not the only device made by MeccatroniCore. The company also produces a “Studio” line of desktop 3D printers targeted at “semi professionals”.

The Studio 200 offers a 210 x 210 x 260mm build volume, while it’s larger sibling, the Studio 300, has a 310 x 210 x 260mm volume. Each machine is capable of 3D printing the same extensive list of materials as the Leonardo 300, but with only a single extruder. It’s also an open-to-the-air machine and not fully enclosed. These machines are priced at €2,300 (USD$2,400) and €2,700 (USD$2,800).

There’s one catch with these machines: they are built to use 220-240V input power, not 120V as is used in some regions, so be aware you may need power conversion.

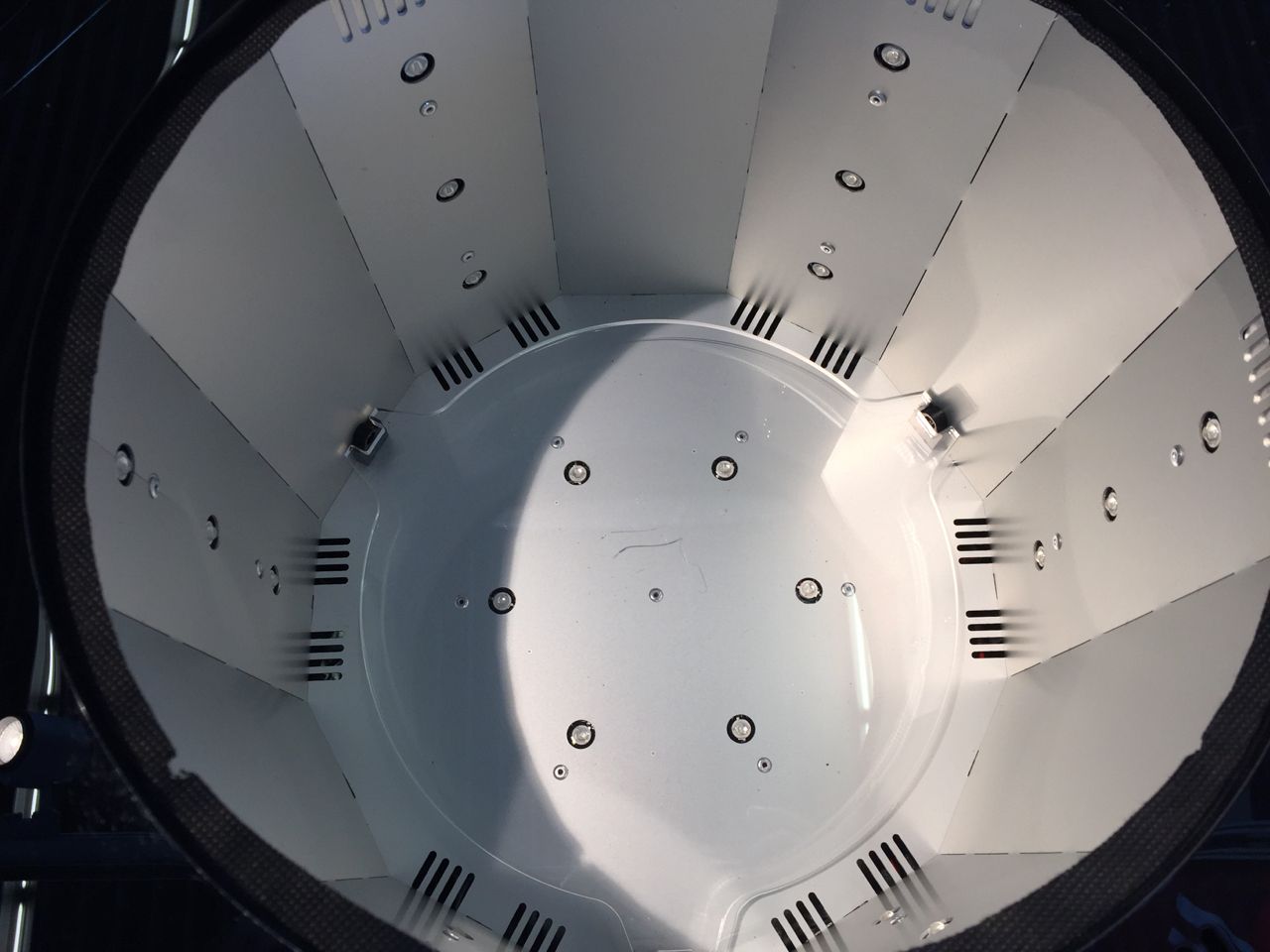

Finally, MeccatroniCore also markets a very unusual device, the BB Cure UV curing system. This is a machine that accepts freshly 3D printed objects from a resin-based 3D printer using photopolymers and bathes it in UV light to increase the strength by continuing the photocuring process.

The BB Cure is targeted at jewelry (€900, USD$945) and dental (€1,200 USD$1,260) operations using resin-based 3D printing. It’s a very flexible unit that has a large curing chamber, able to accommodate prints from multiple machines at once, as you can see here. The machine can set different temperatures to ensure optimum curing time and effectiveness.

I say this machine is unusual because MeccatroniCore does not produce a resin-based 3D printer! Their product line is otherwise entirely filament-based and does not require UV curing. Thus, they’re really addressing the shortcomings of other vendors with the BB Cure.

Via Meccatronicore